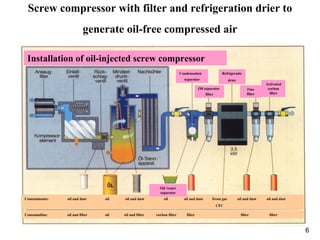

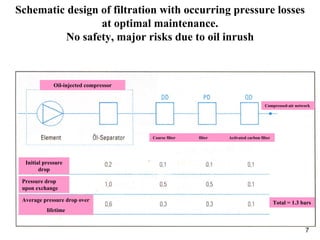

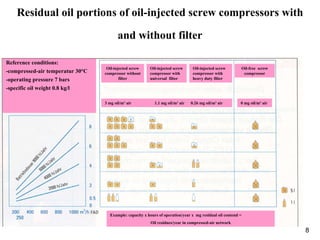

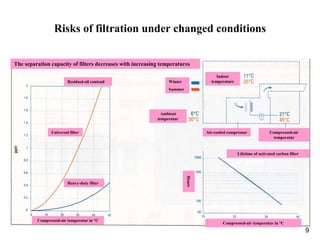

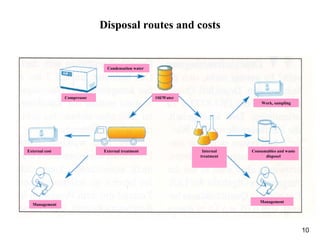

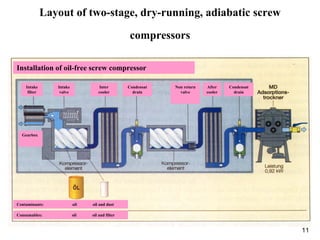

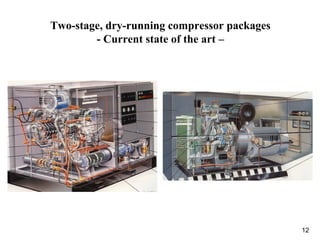

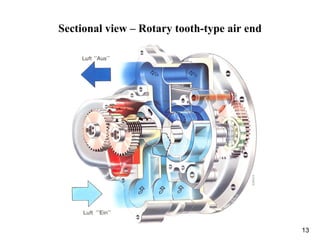

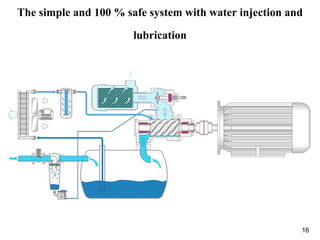

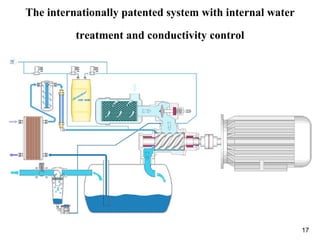

The document discusses oil-free compressor systems. It notes that oil-free compressed air is required for applications involving food, pharmaceuticals, and clean rooms. It then describes the GVM compressor system as being oil-free and able to generate compressed air continuously with low energy and maintenance costs. The system avoids risks from oil in the compressed air network. The document also discusses other oil-free compressor options that require cooling systems and filters that can become contaminated over time.