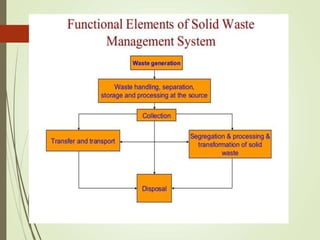

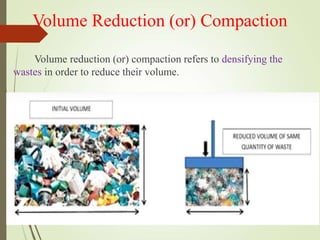

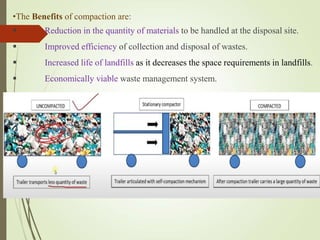

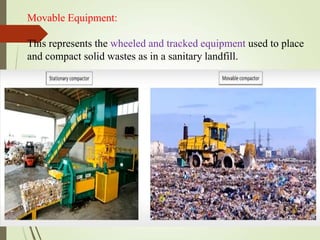

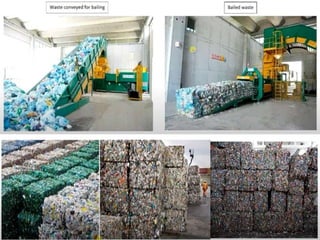

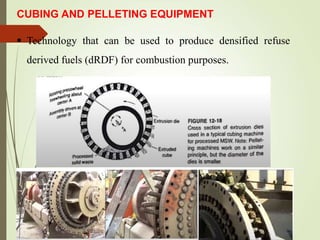

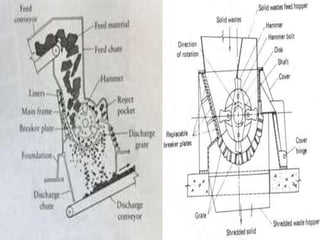

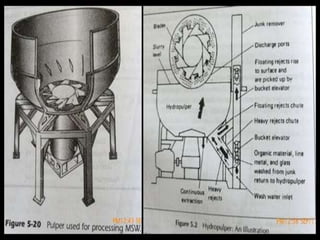

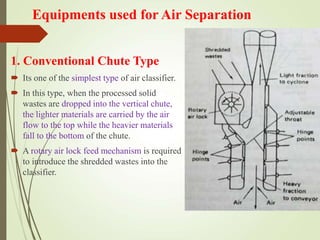

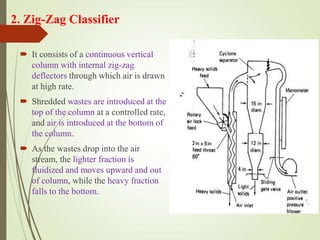

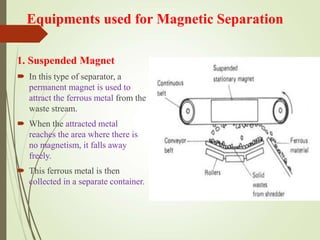

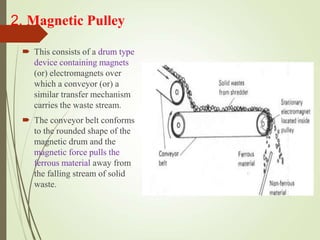

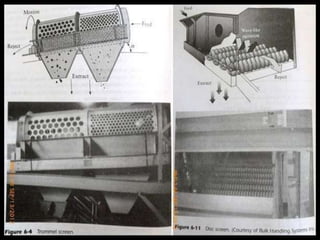

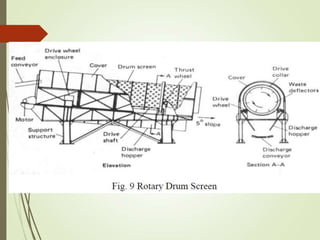

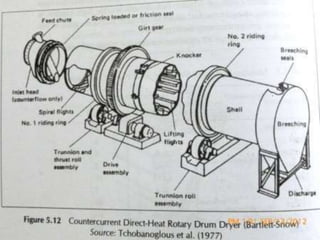

This document discusses processing techniques for municipal solid waste management. It describes various physical processing techniques including mechanical volume and size reduction through compaction and shredding. It also discusses component separation techniques like air separation, magnetic separation, and screening. Drying and dewatering operations are described which are used to reduce moisture content before thermal processing or landfilling. Specific equipment for tasks like baling, cubing, hammer mills, hydro-pulpers, suspended magnets, and magnetic pulleys are outlined. The objectives of processing include improving waste management system efficiency, recovering materials and energy from waste streams.