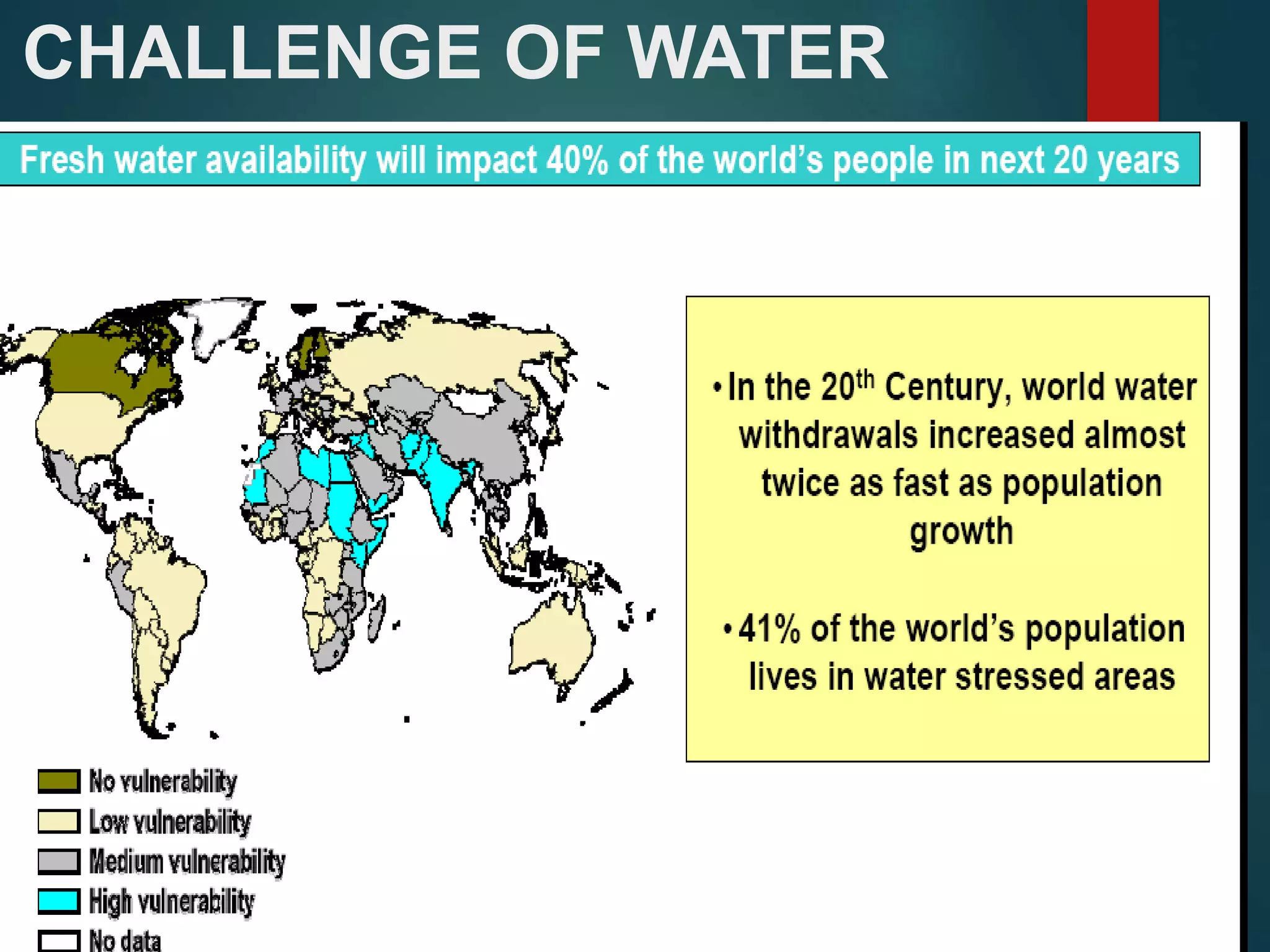

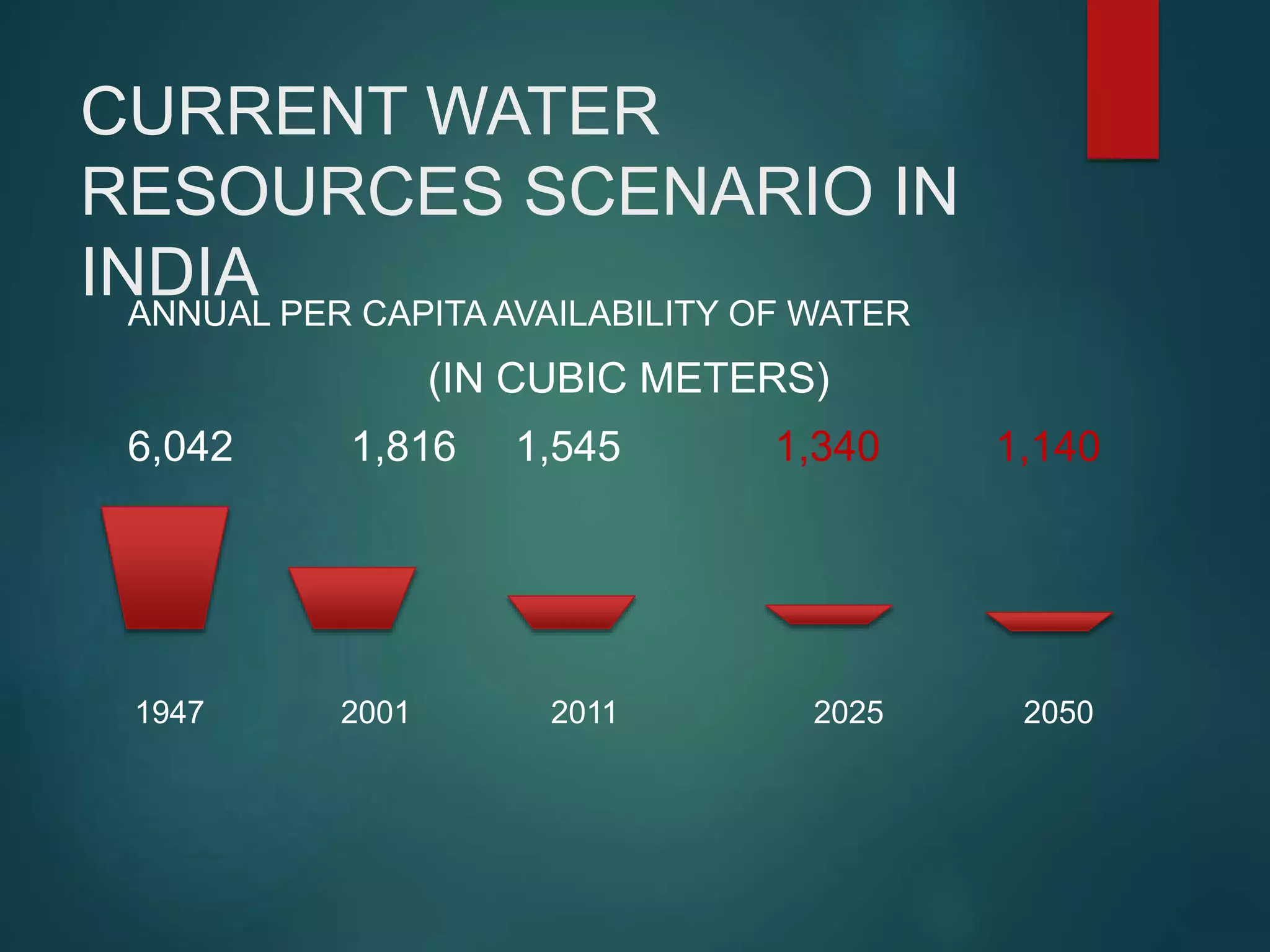

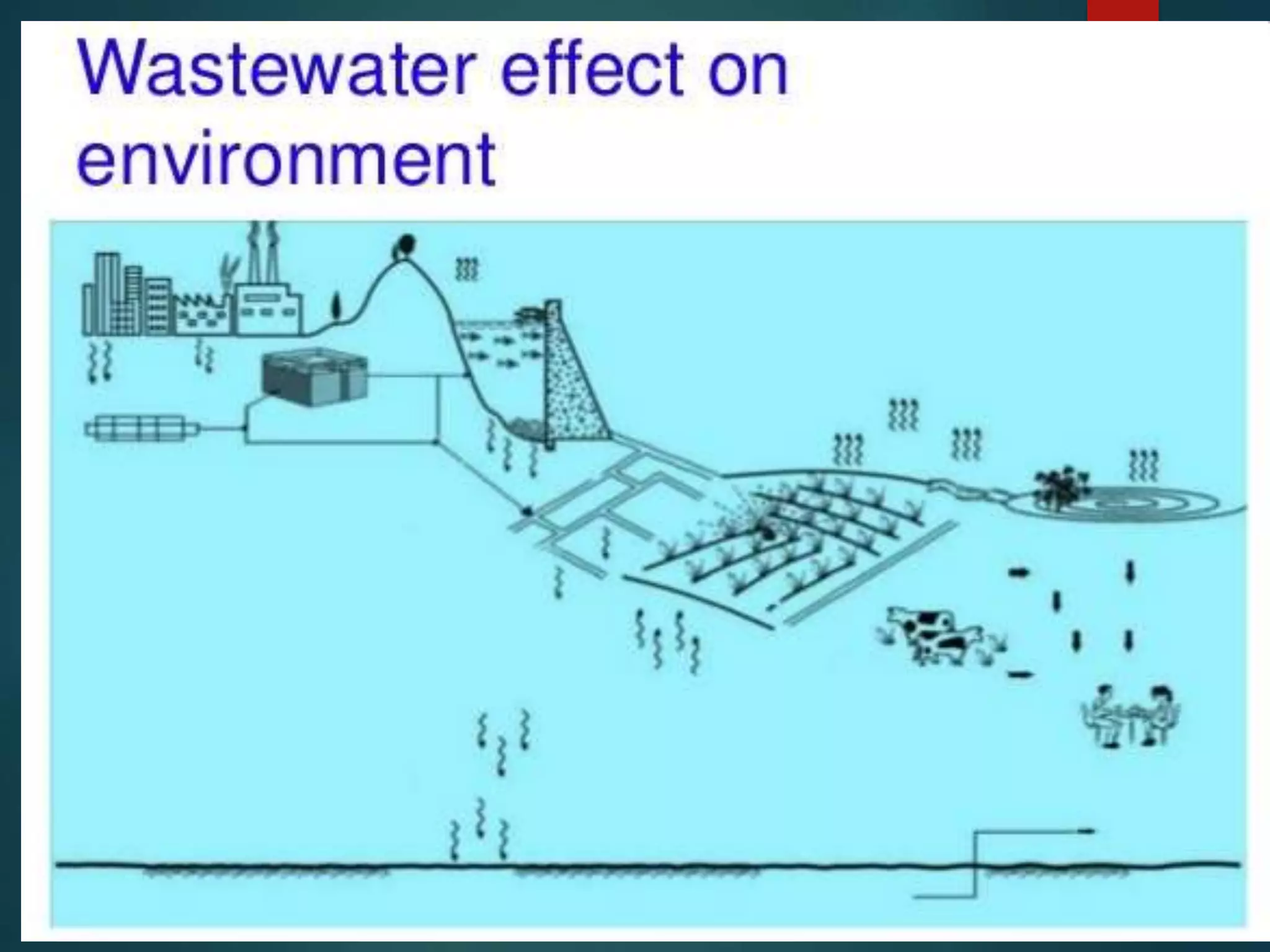

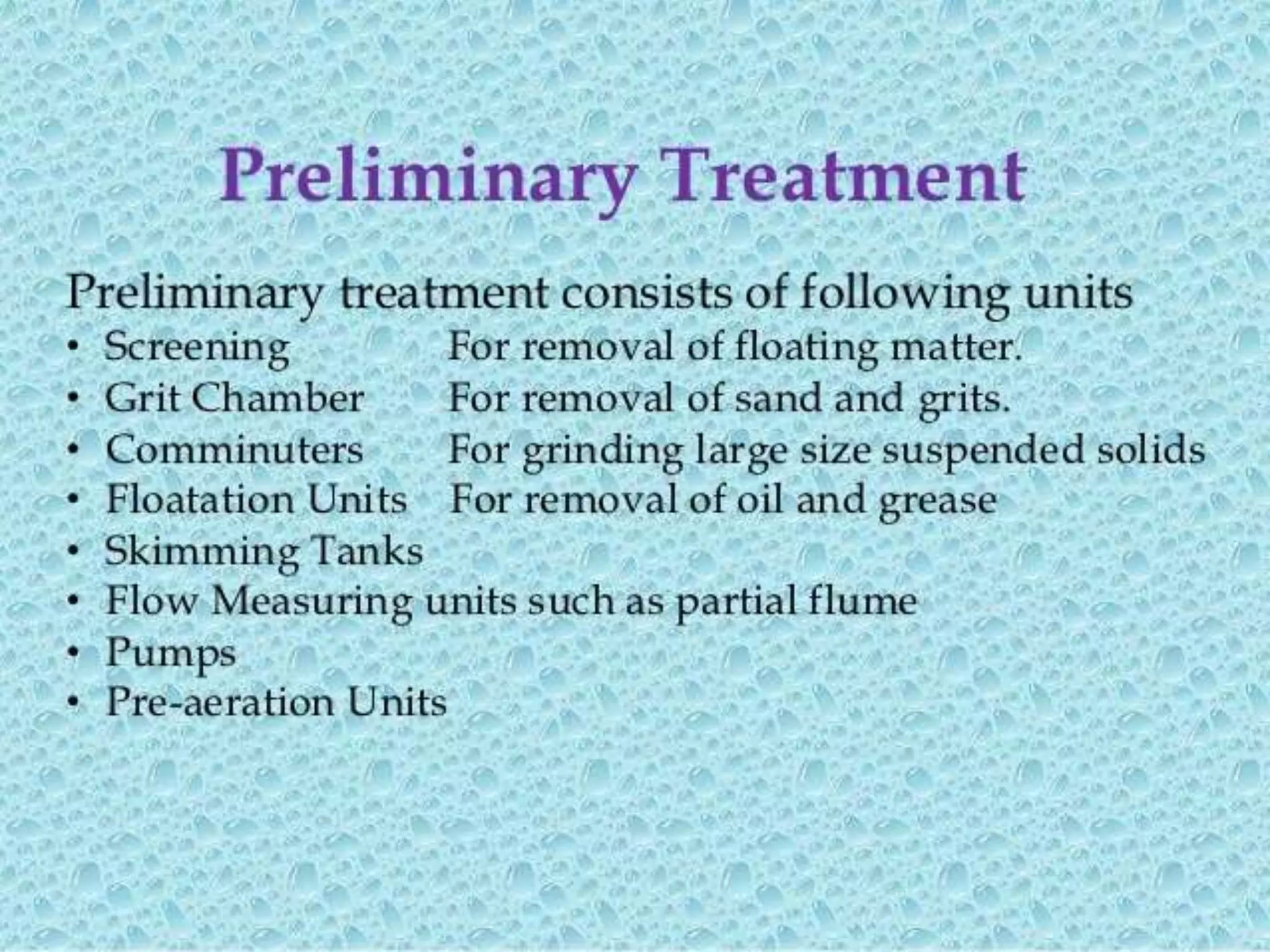

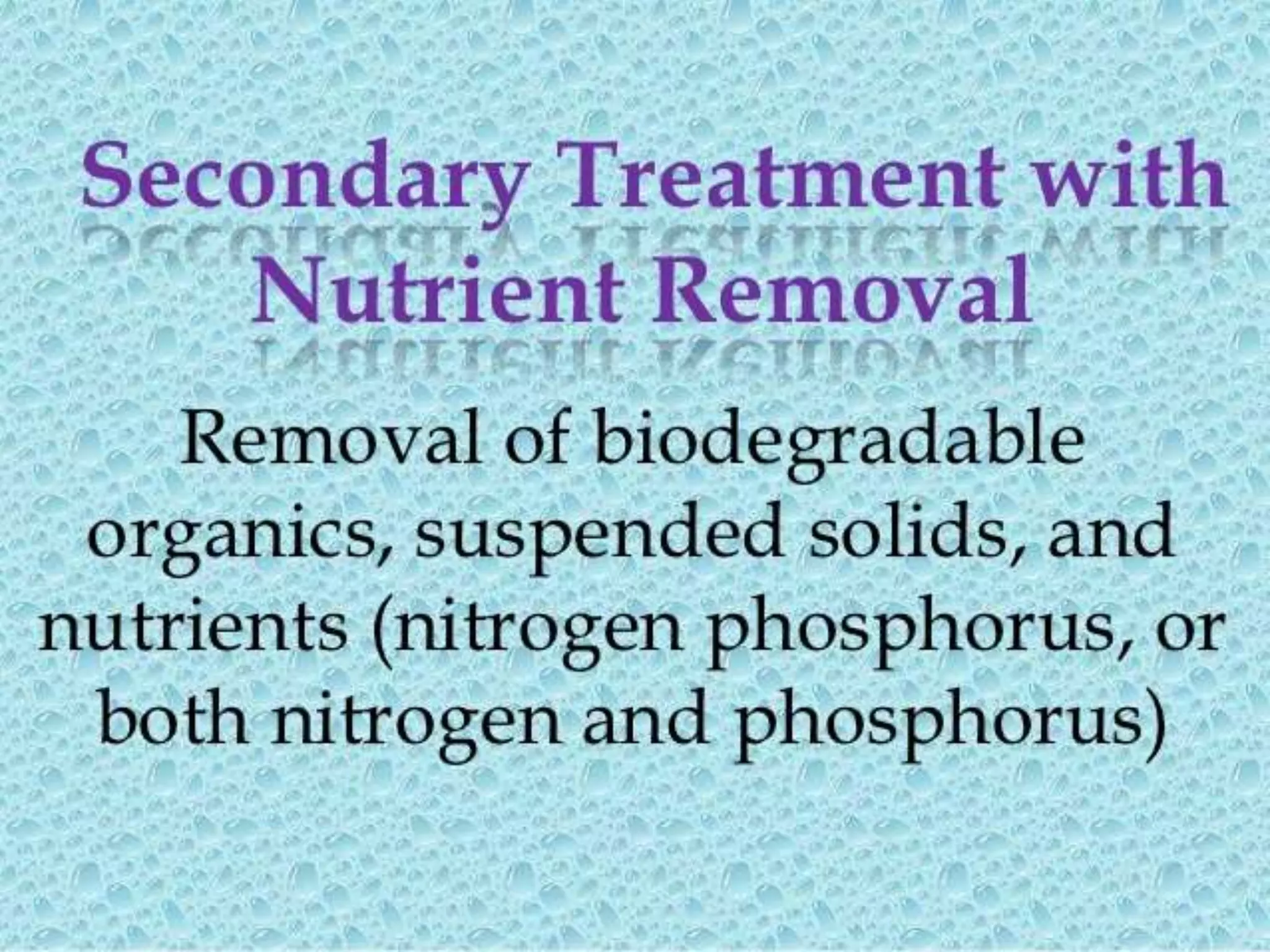

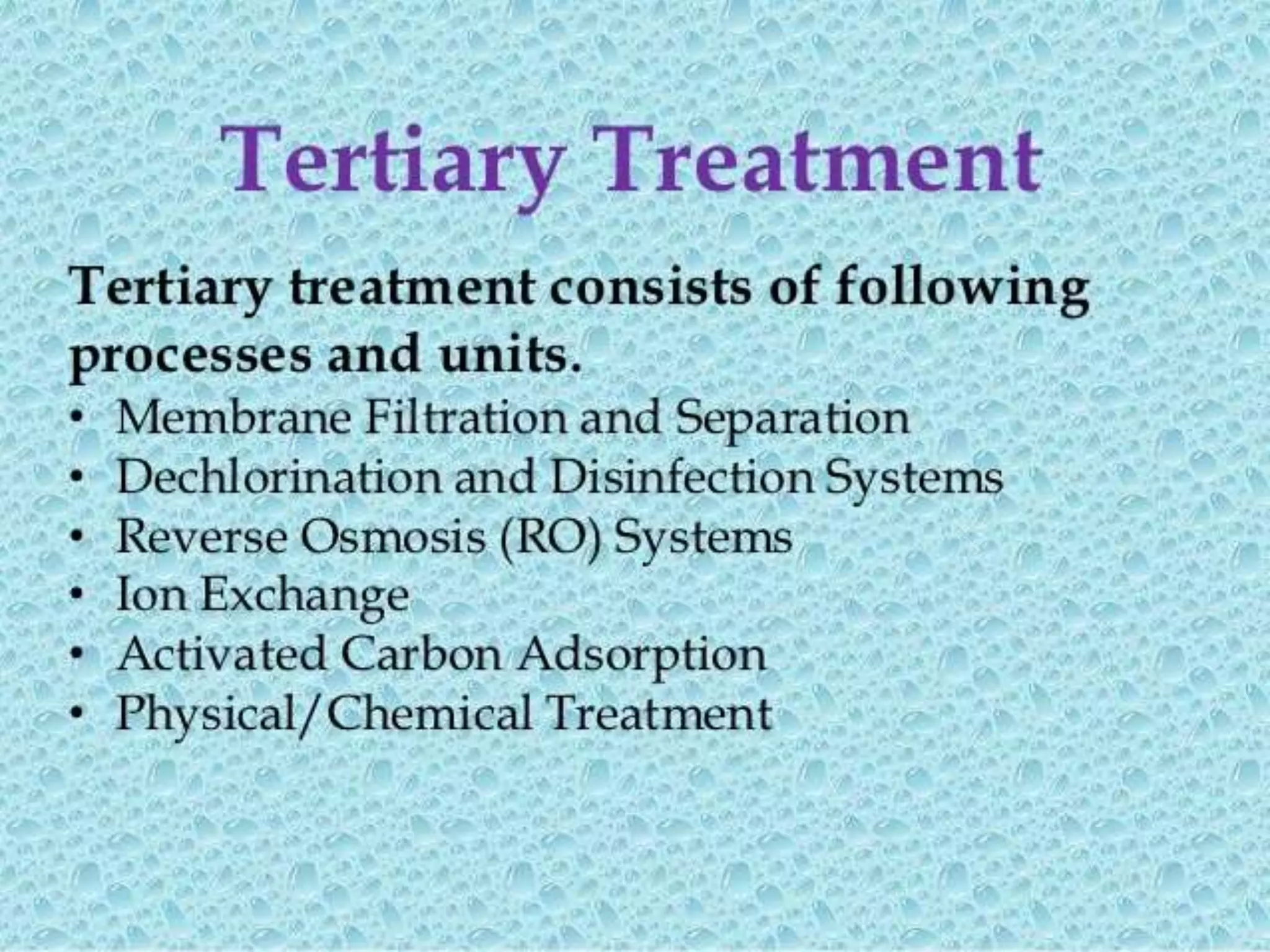

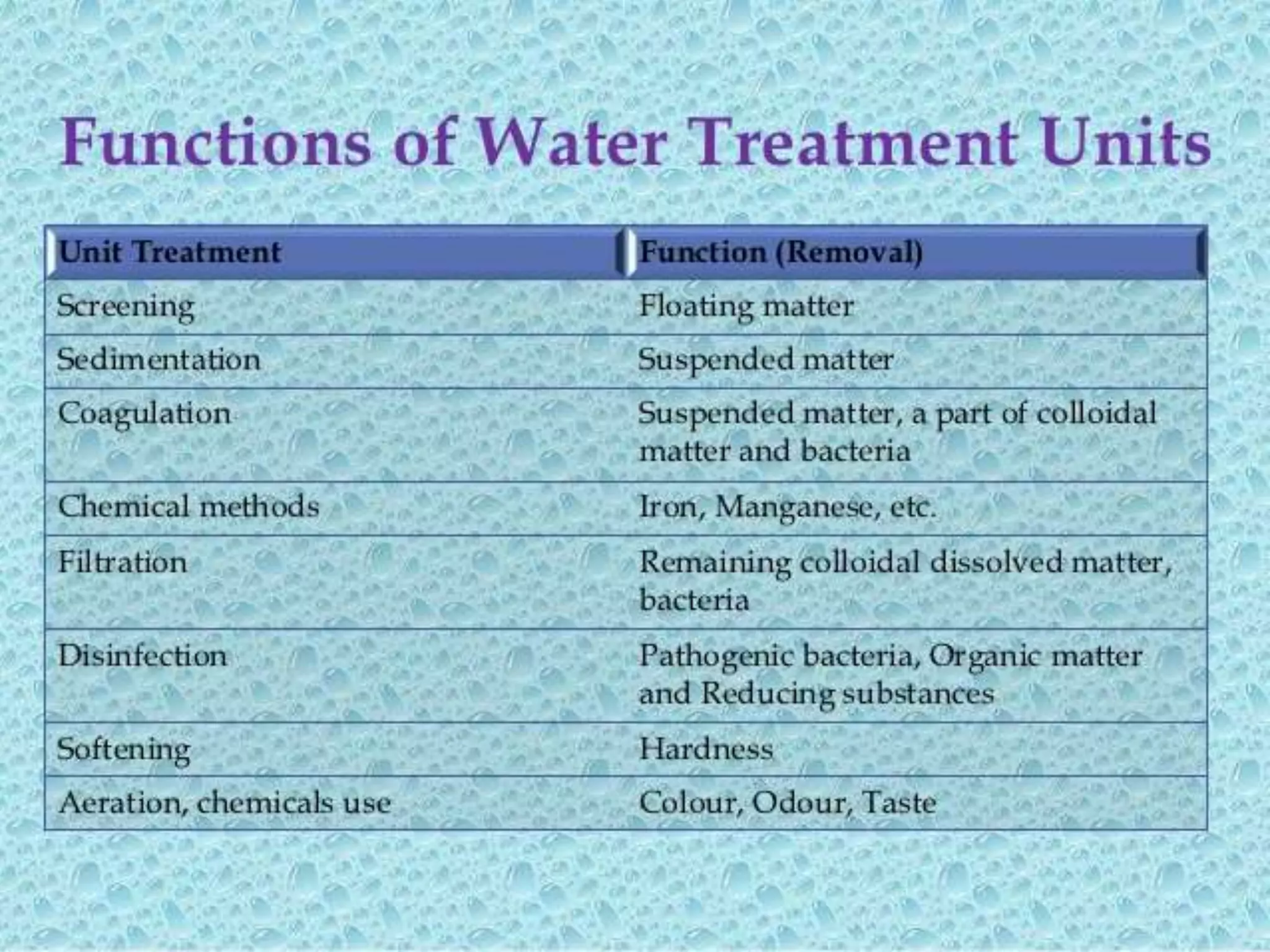

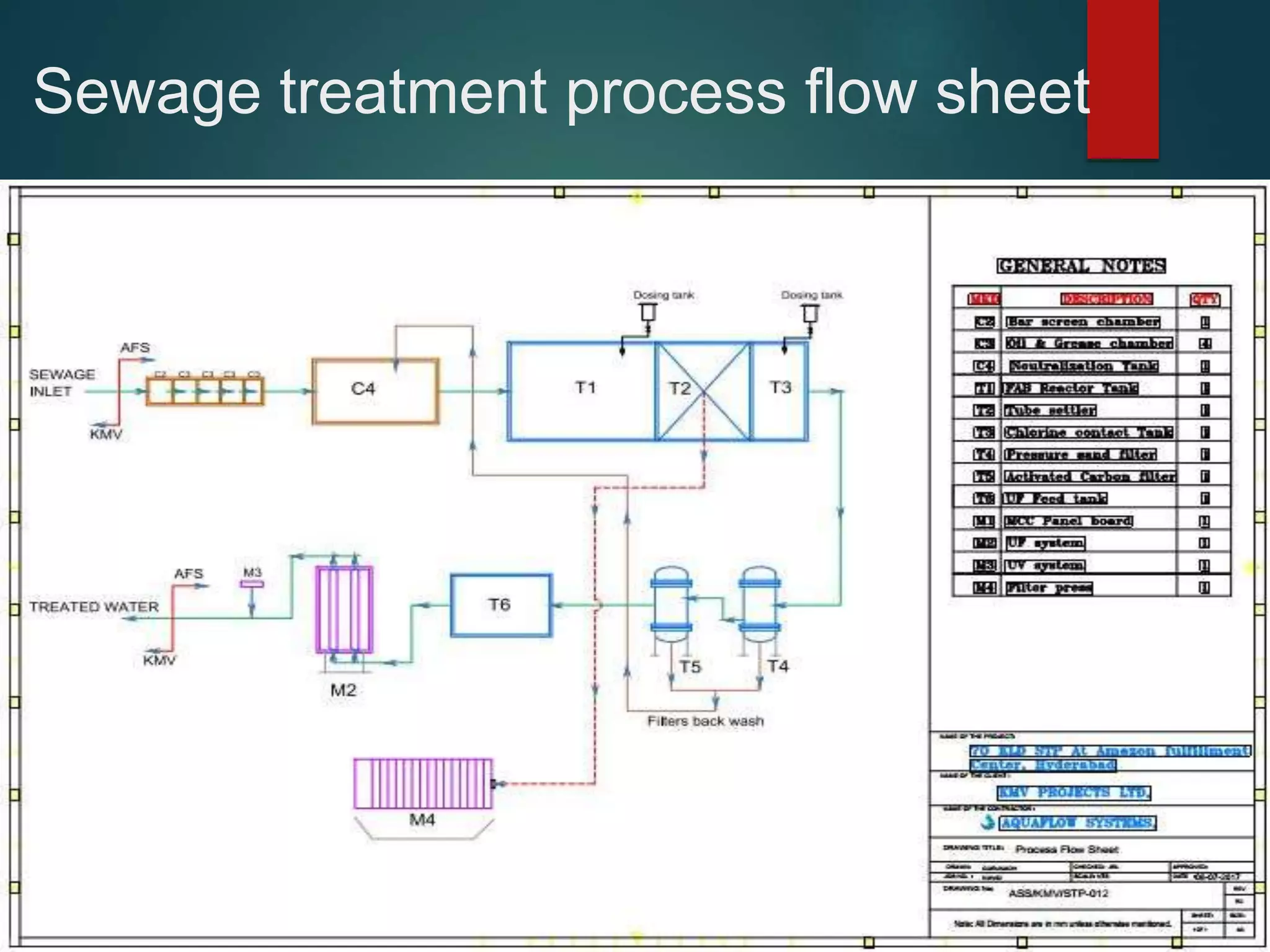

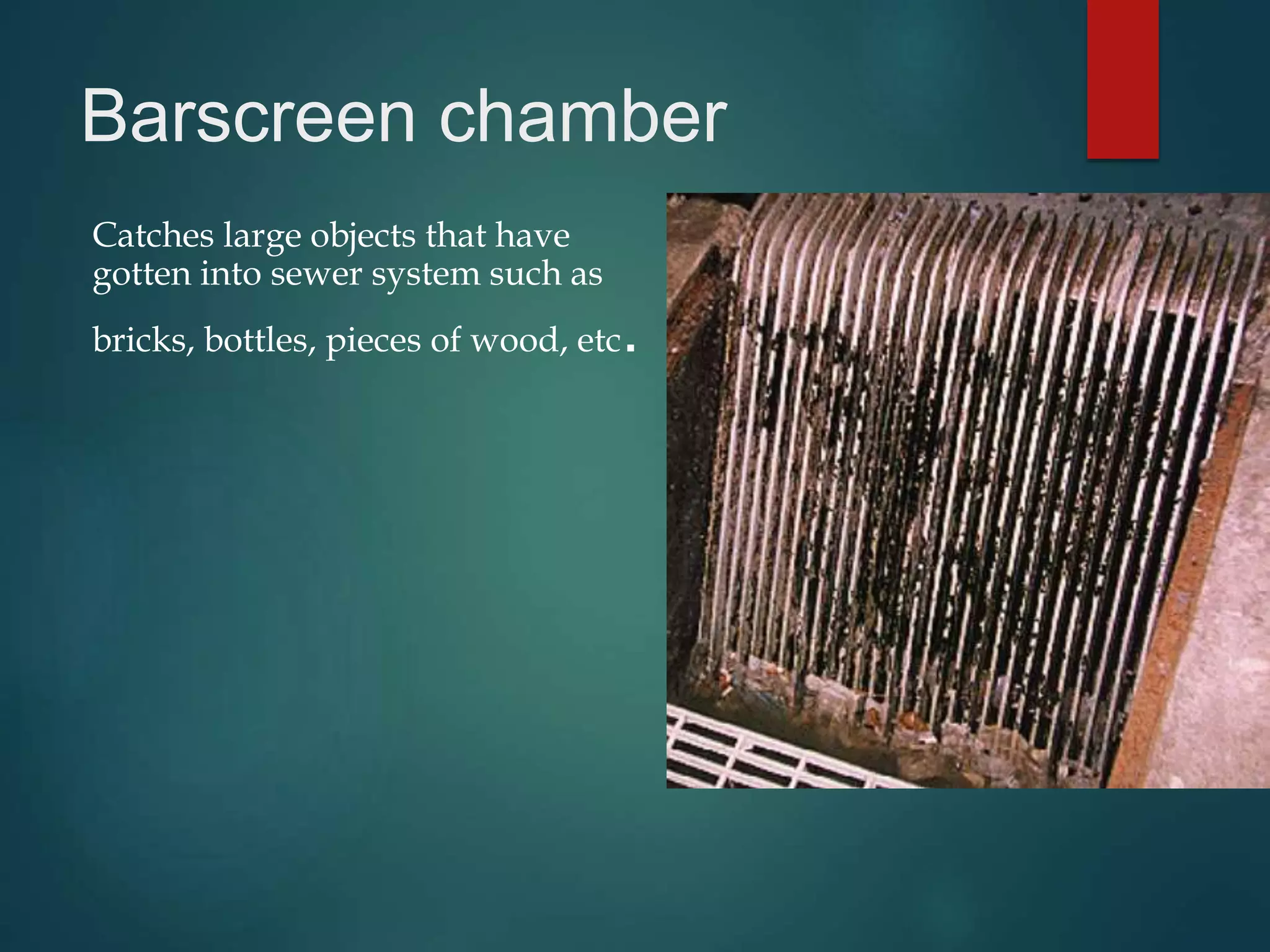

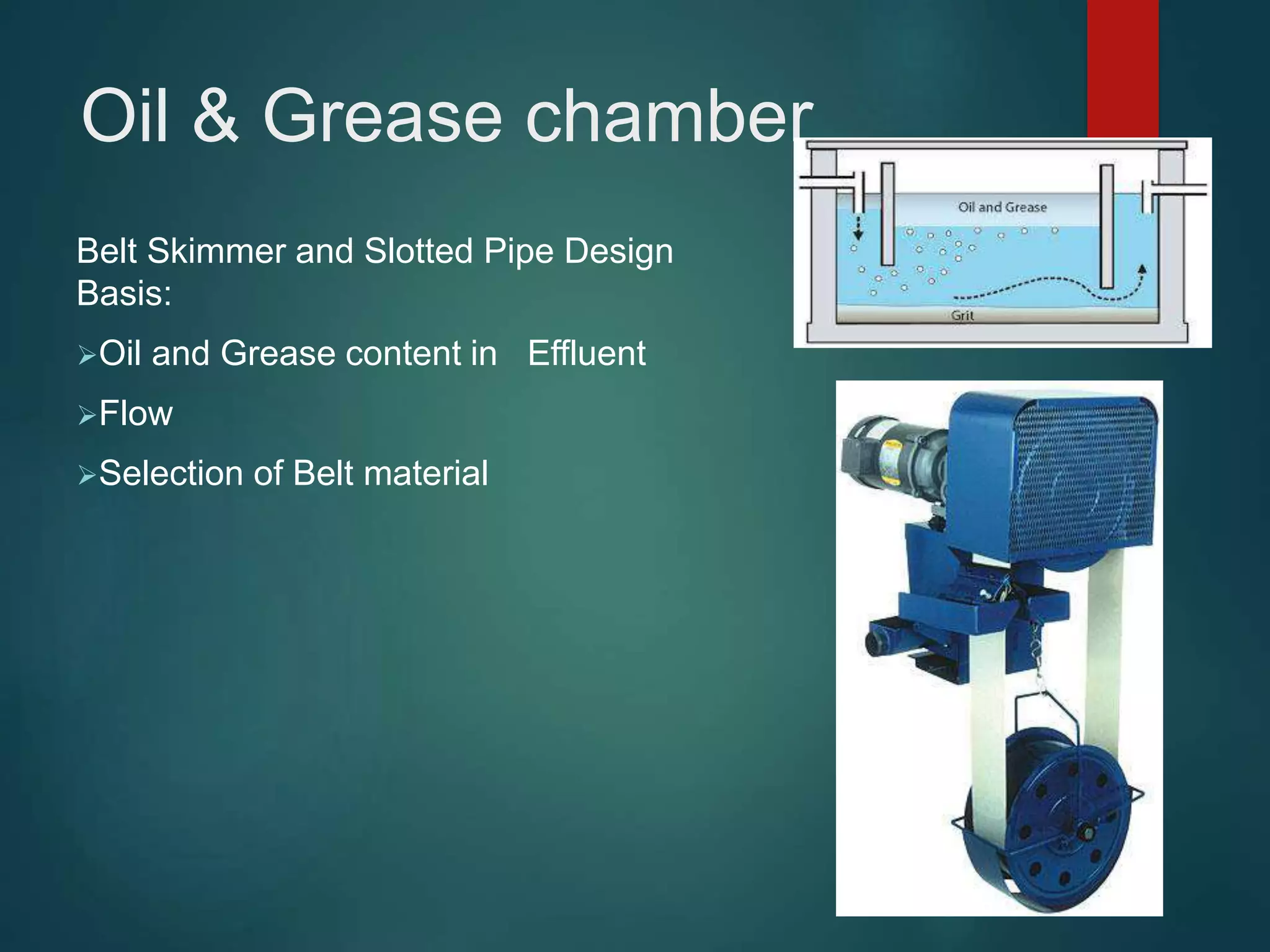

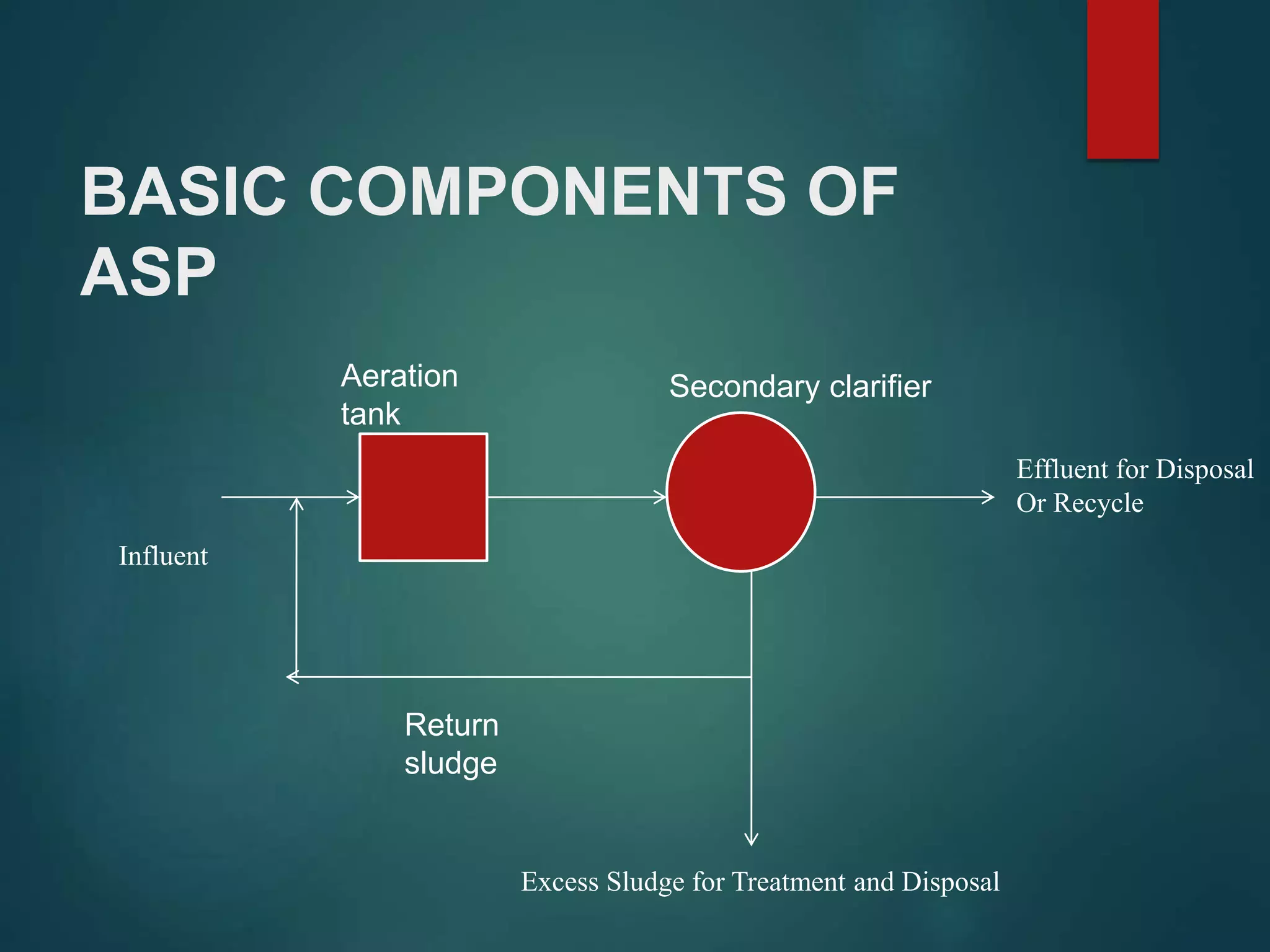

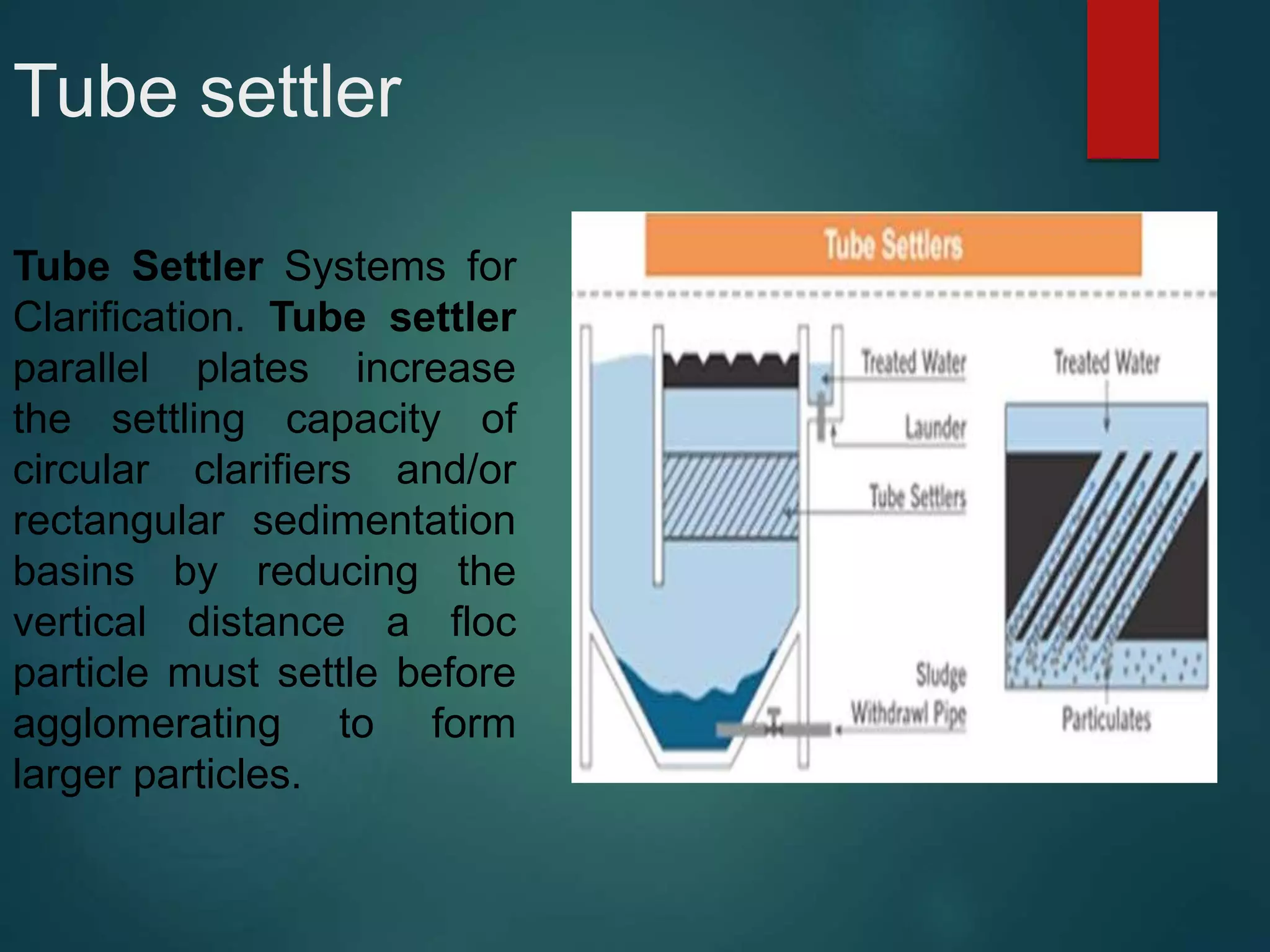

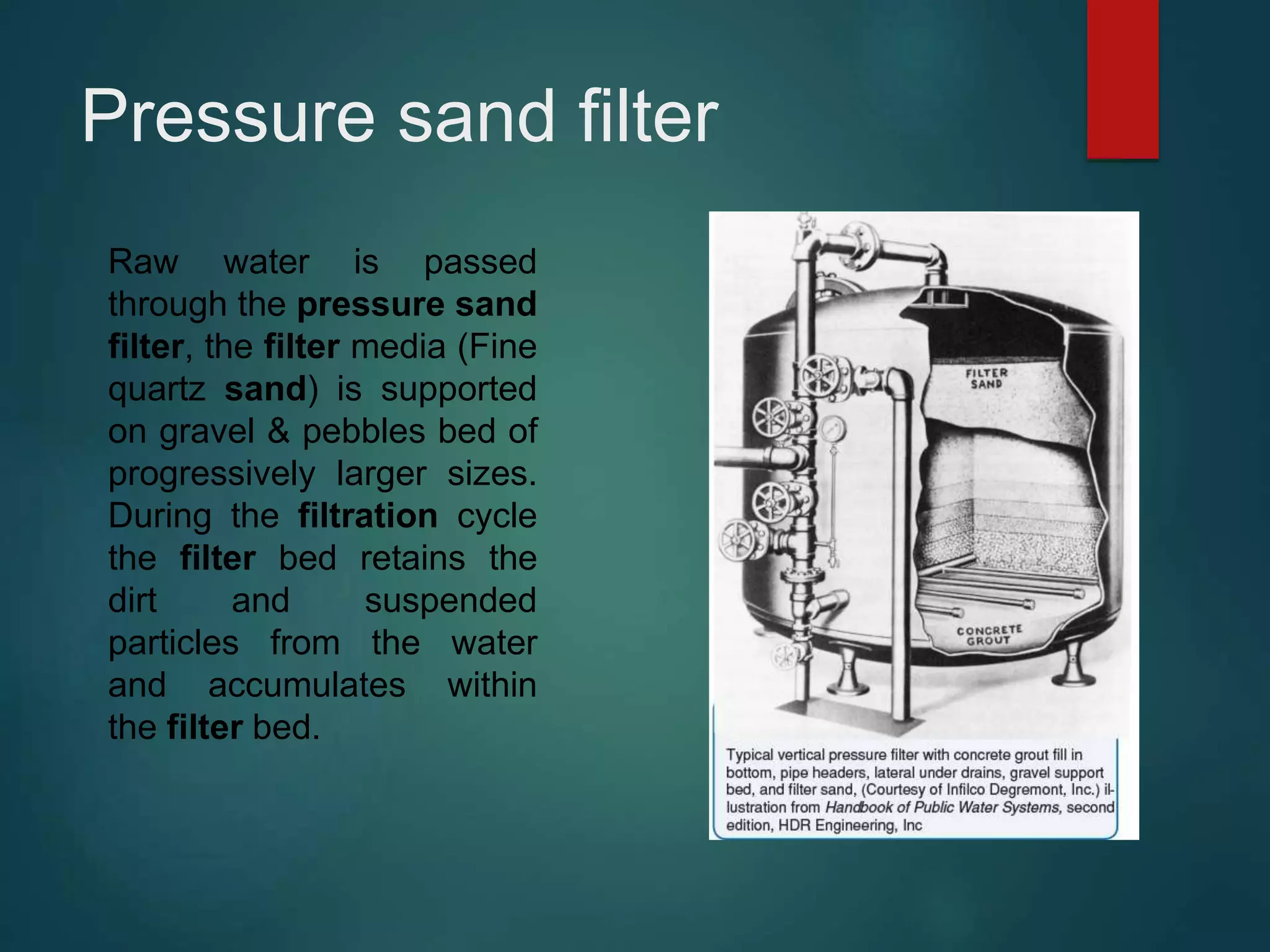

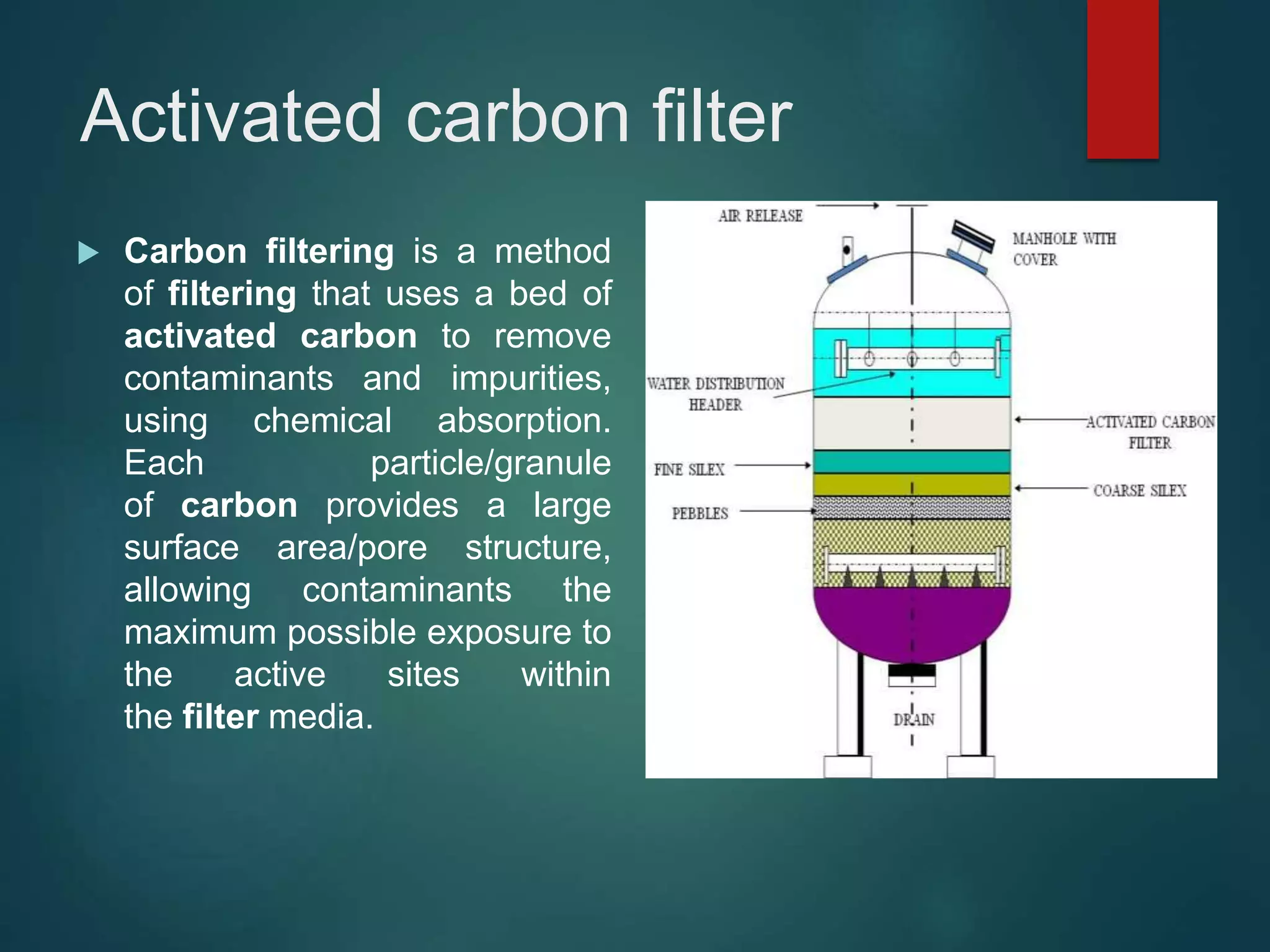

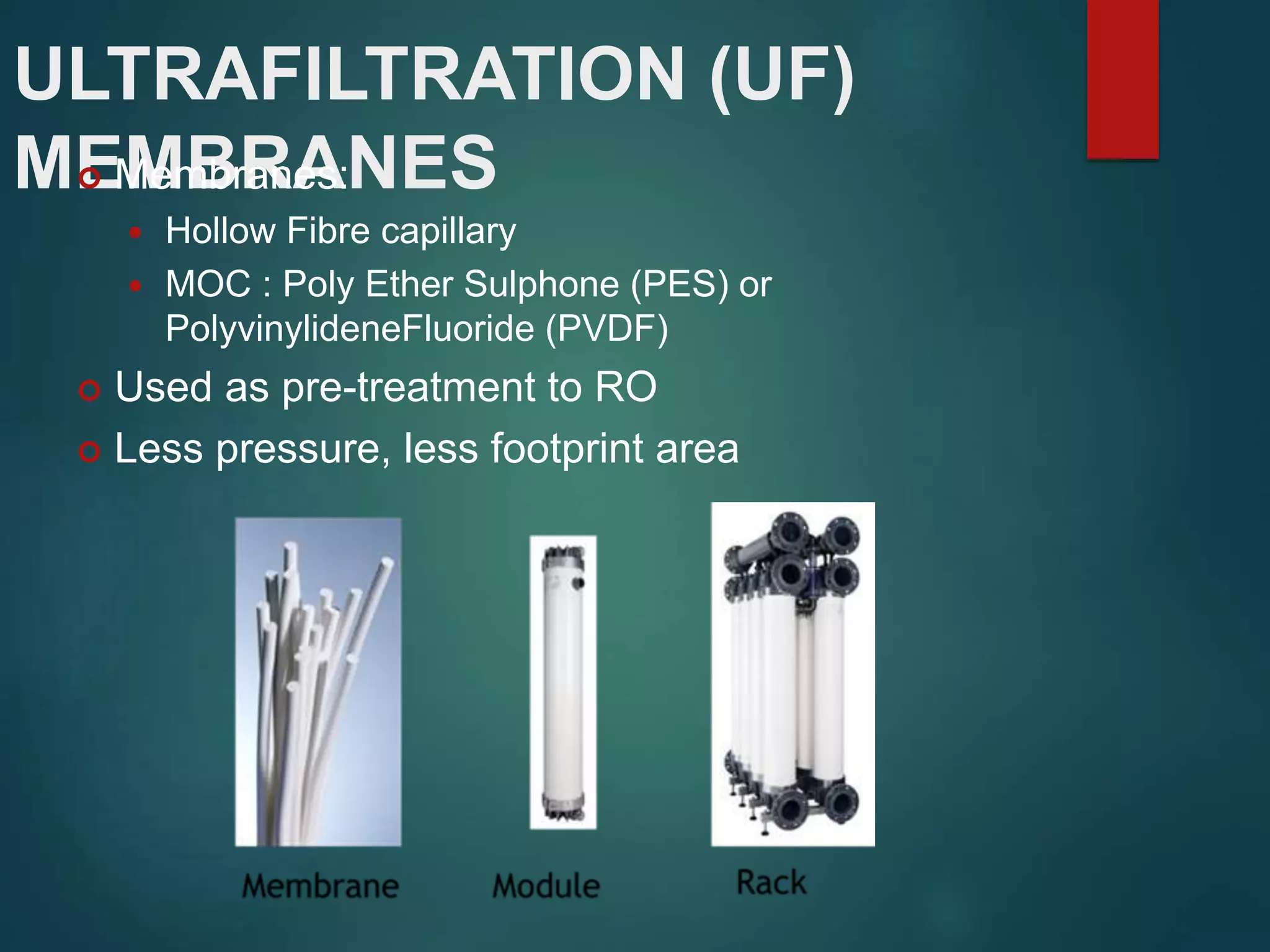

This document provides an overview of water issues and sewage treatment processes. It discusses the global water crisis, reasons for water scarcity in India like increasing demand and decreasing supply. It then describes the various unit processes involved in sewage treatment like bar screens, neutralization, activated sludge process using aeration tanks and secondary clarifiers, and tertiary treatment using processes like filtration and UV disinfection. The importance of proper operation and maintenance of sewage treatment plants is also emphasized.