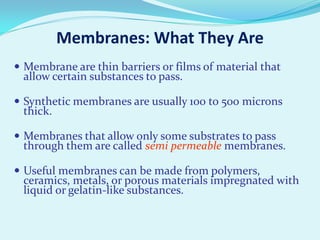

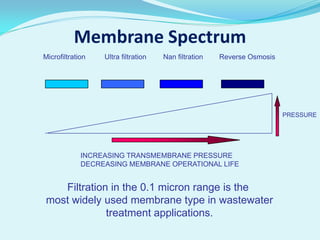

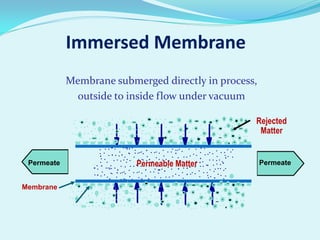

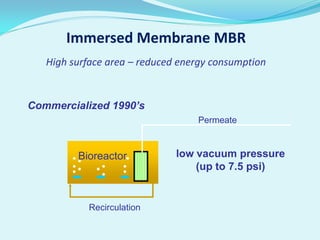

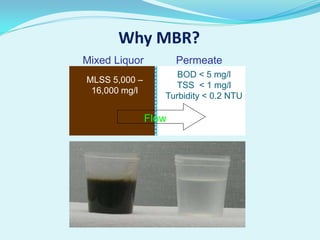

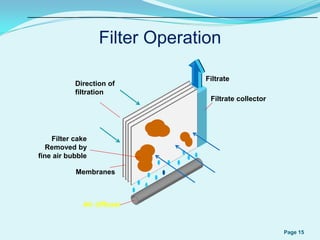

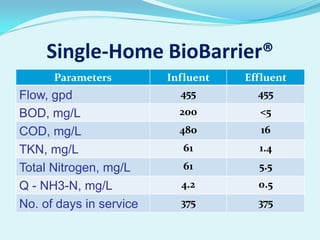

Membrane bioreactor (MBR) technology offers a high-quality solution for on-site wastewater treatment, utilizing semi-permeable membranes to effectively remove contaminants. MBR systems are energy-efficient, easy to operate, and capable of handling difficult wastewater with consistent nutrient removal and effluent quality. Conclusively, MBR technology is a feasible option for residential and commercial applications, providing automated and low-maintenance operations.