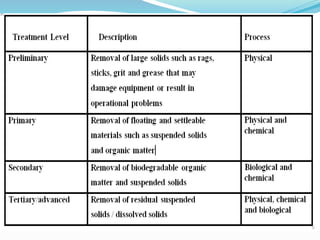

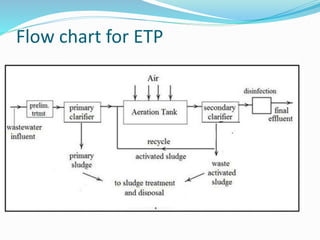

This document discusses the importance of effluent treatment plants (ETPs) and their design and operation. It begins by explaining how water is essential for life and industries, and that ETPs are needed to treat industrial wastewater before recycling or discharge. It then describes the key components of ETP design based on factors like wastewater quantity and quality. Finally, it outlines the common treatment methods used at ETPs, including physical, chemical and biological processes at preliminary, primary, secondary and tertiary levels.