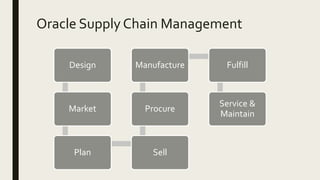

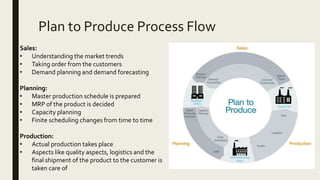

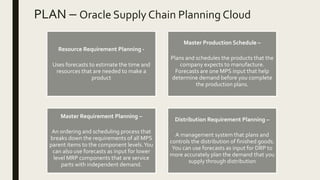

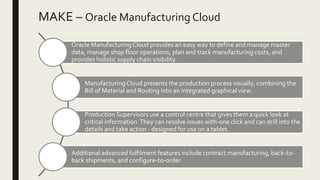

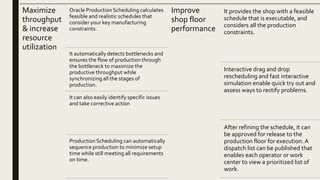

The document describes Plan to Produce, Oracle's supply chain management solution. It discusses the key processes involved - planning production based on sales and forecasts, scheduling production, and optimizing manufacturing operations. Oracle Supply Chain Planning Cloud, Manufacturing Cloud, and Manufacturing Intelligence solutions help maximize throughput, increase utilization of resources, and provide visibility and analytics across the supply chain. Case studies show how customers streamlined processes, improved reporting and cash flow, reduced wastage and saved time through automation.