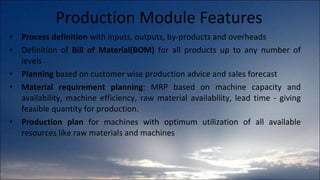

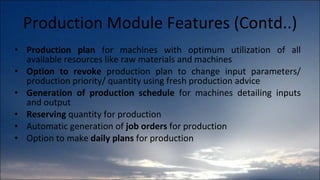

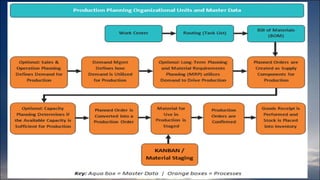

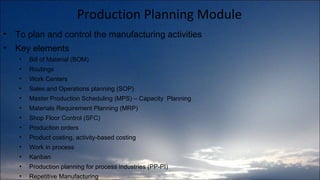

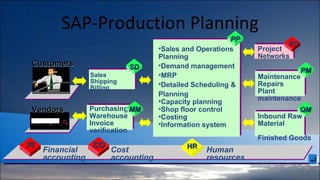

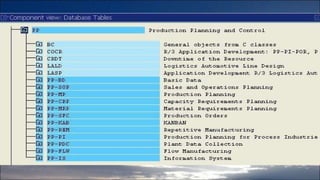

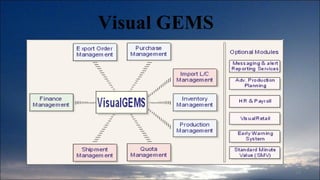

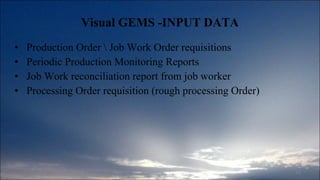

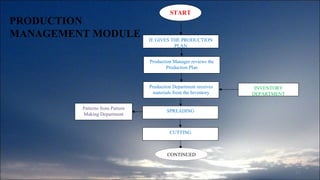

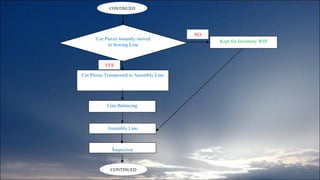

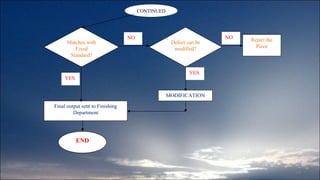

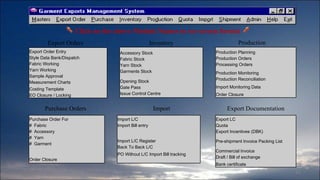

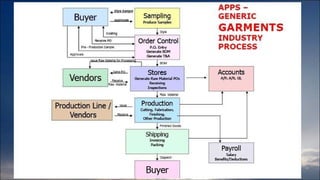

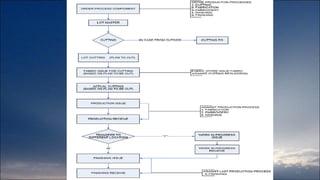

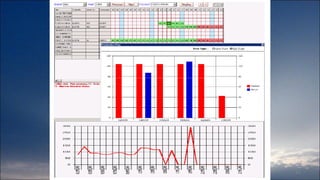

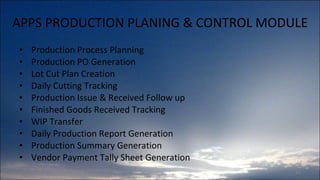

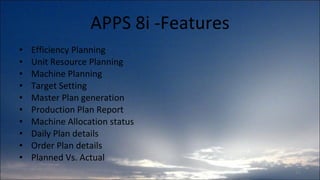

The production module of ERP systems is designed to facilitate production planning, taking orders, and delivering products to customers. It allows for process definition, bill of material creation, material requirements planning based on machine capacity, production planning to optimize resource utilization, and automatic generation of job orders and daily production plans. Key features include production scheduling, reserving materials for production, and options to change production plans.