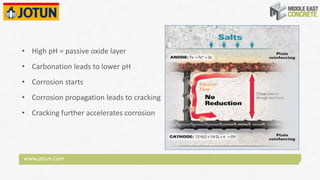

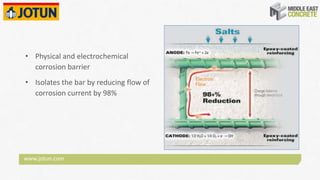

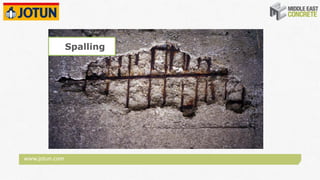

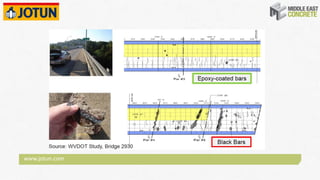

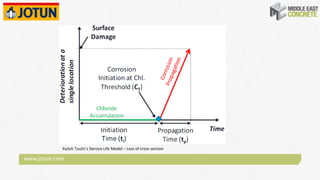

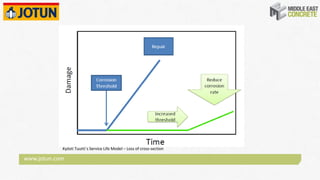

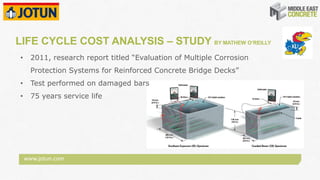

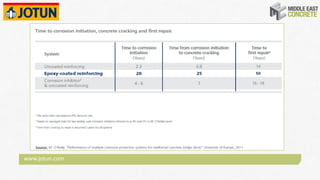

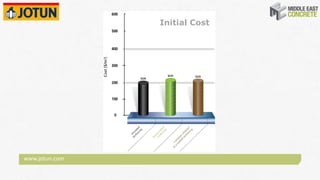

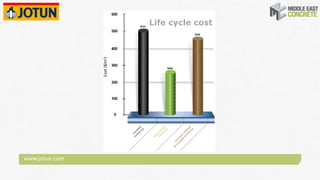

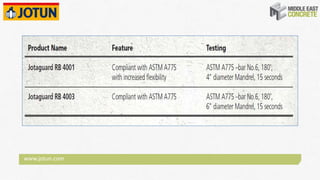

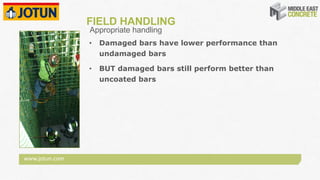

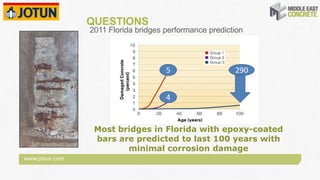

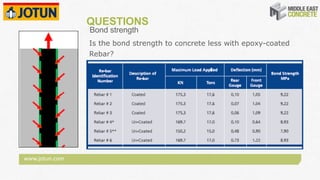

The document discusses the benefits of epoxy coating for steel rebar in concrete structures, particularly in GCC countries, highlighting its ability to significantly reduce corrosion and maintenance costs. It covers various corrosion protection methods, the initial and life cycle costs of using fusion-bonded epoxy coating, and emphasizes the importance of proper handling and application of coated rebar. The conclusion asserts that epoxy coatings provide the lowest life cycle cost and enhance the service life of concrete structures to 75-100 years.

![www.jotun.com

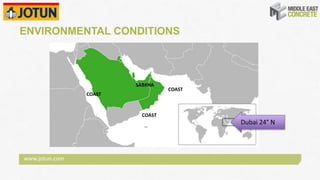

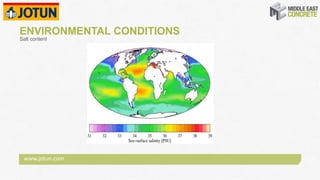

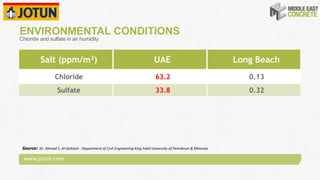

ENVIRONMENTAL CONDITIONS

Sabkha brine vs. Seawater

Source: Dr. Ahmad S. Al‐Gahtani ‐ Department of Civil Engineering King Fahd University of Petroleum & Minerals

Ions (g/l) Sabkha brine Sea water

Cl- 157.2 36.9

SO4-- 5.45 5.12

pH [n/a] 6.9 8.3

Conductivity [µmhos/cm] 208,000 46,200](https://image.slidesharecdn.com/11-150813113058-lva1-app6891/85/Epoxy-Coating-For-Steel-Rebar-14-320.jpg)