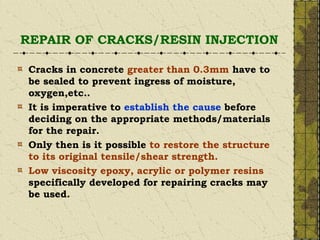

This document discusses polymers used for concrete repair. It describes two main types of polymers: those used to modify cementitious systems and thermosetting resin systems like epoxy, polyester, and acrylic. Polymer latexes are used as admixtures in cementitious systems where they improve properties like strength, permeability, and bonding. Resin repair mortars are used for smaller repairs under 12mm and rely on impermeability for steel protection. Epoxy, polyester, and acrylic resins are discussed in more detail regarding their chemical curing processes and appropriate uses in concrete repair.