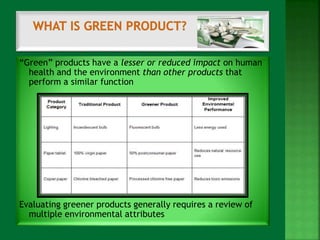

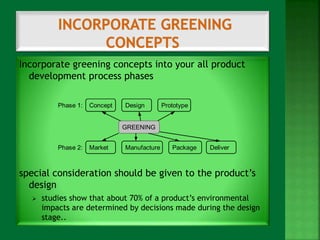

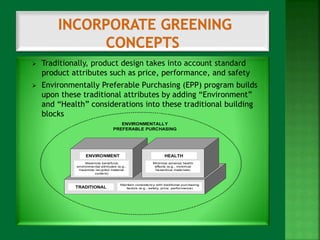

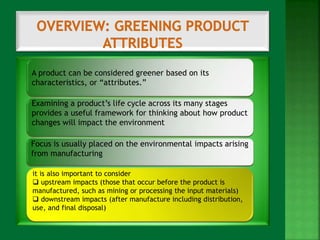

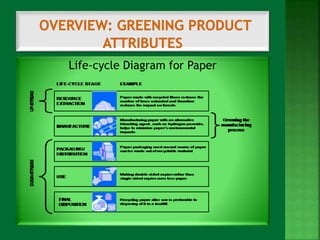

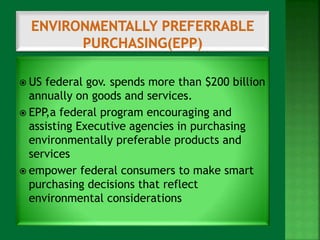

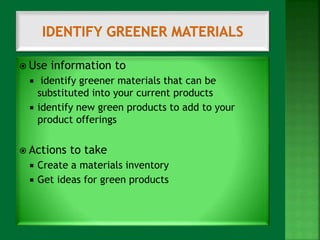

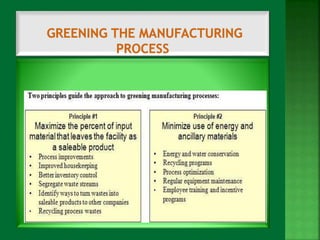

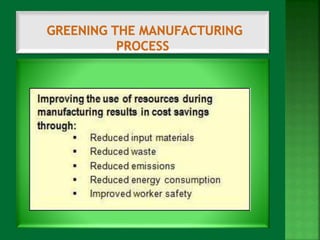

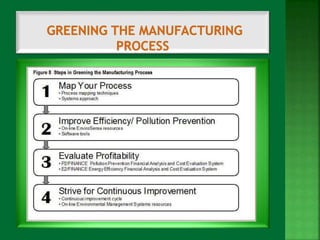

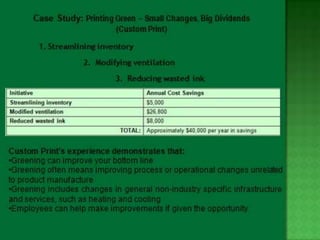

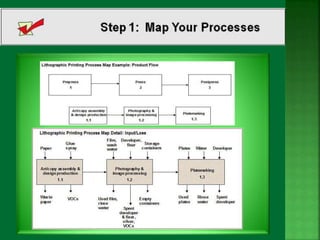

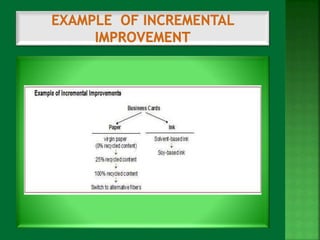

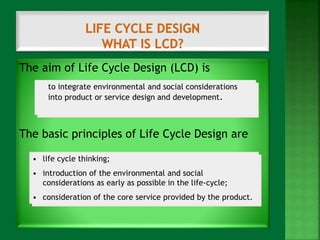

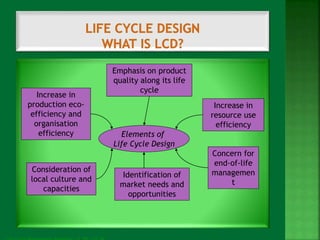

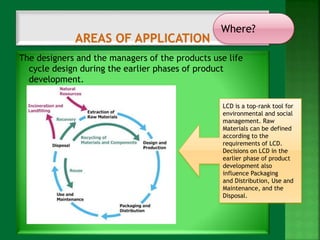

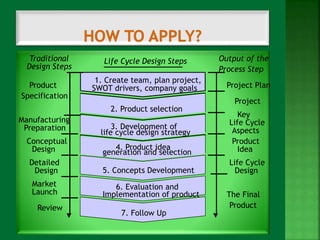

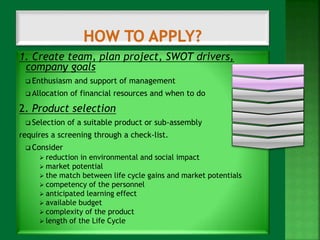

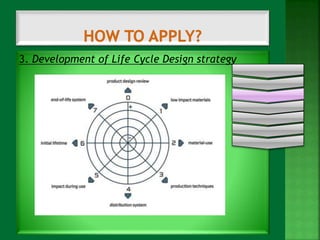

The document discusses greening products by making them more environmentally friendly. It provides tips for businesses on how to introduce green products or improve existing ones. Some key points covered include evaluating a product's environmental impacts throughout its lifecycle from production to disposal, using recycled and recyclable materials, reducing energy usage, and eliminating toxic chemicals. The document also discusses marketing green products and the benefits to businesses of increasing market share and reducing costs through more efficient processes.