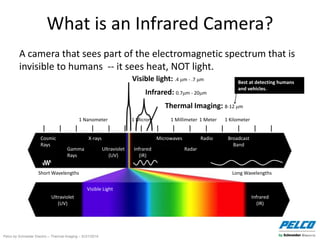

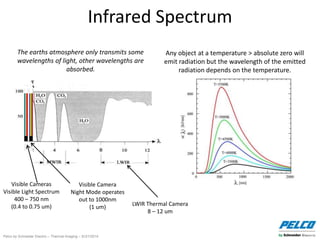

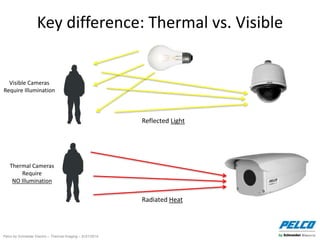

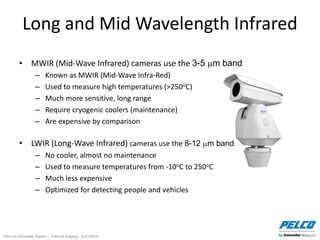

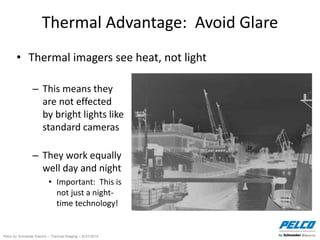

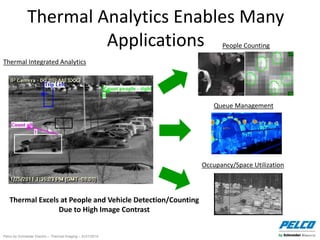

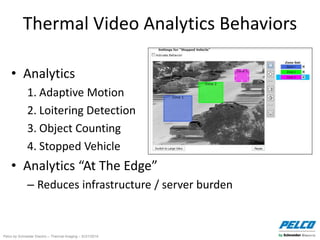

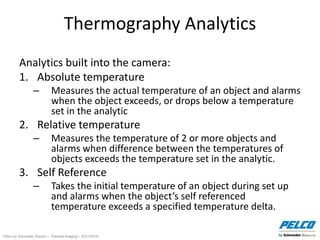

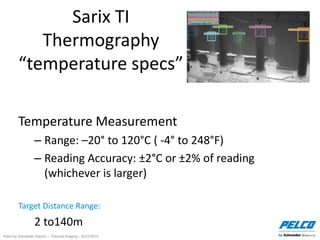

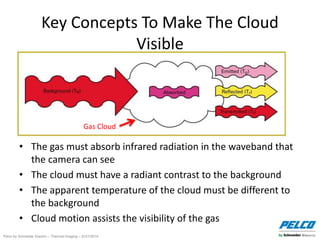

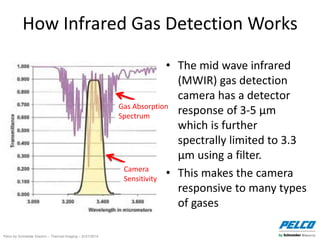

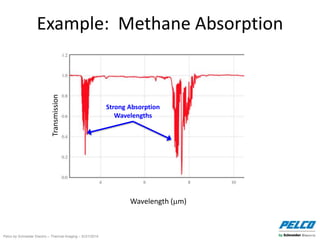

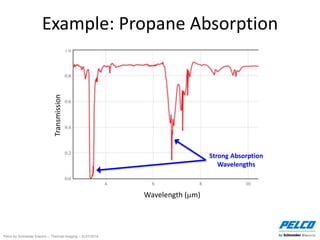

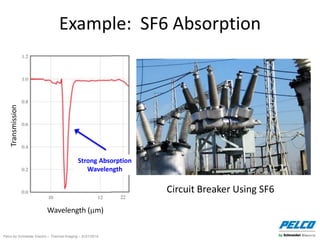

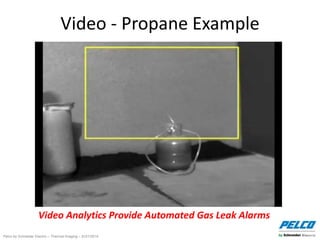

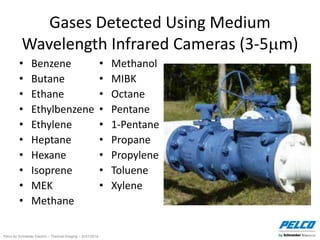

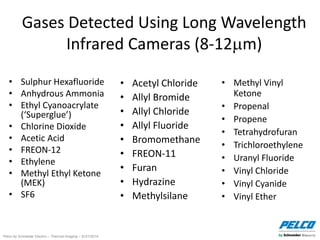

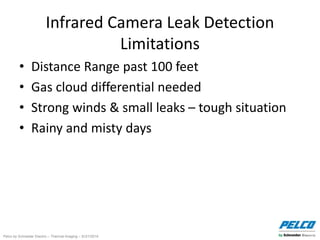

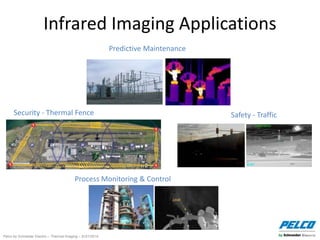

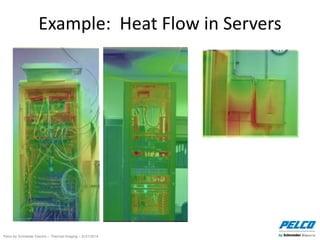

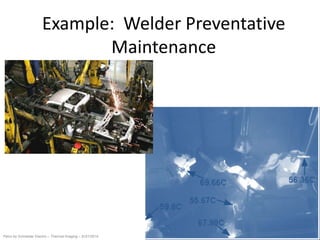

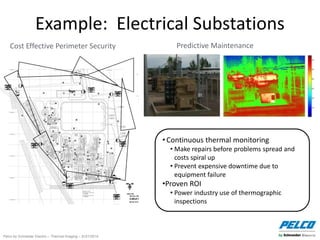

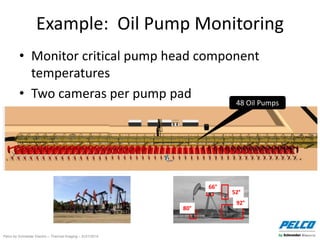

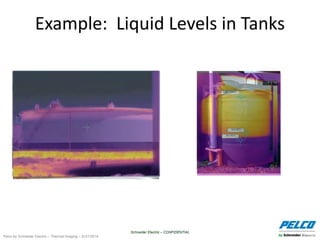

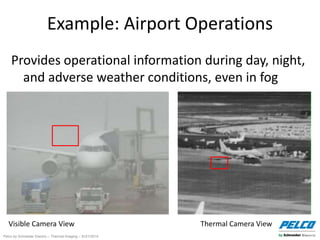

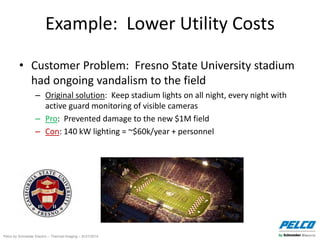

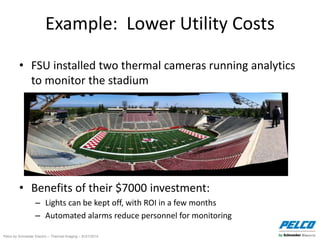

This document provides an overview of infrared technology for operational video. It discusses the fundamentals of infrared technology, including what infrared cameras are and how they work. Unique attributes like the ability to see in total darkness and through obscurants are covered. The document also reviews thermal video analytics for people and vehicle detection, thermography for temperature measurement, and infrared gas leak detection. Finally, examples of operational infrared video are shown for applications like predictive maintenance, security, and process monitoring.