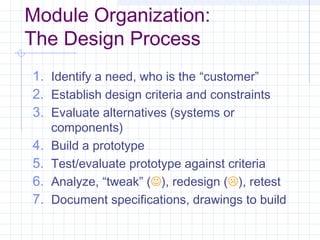

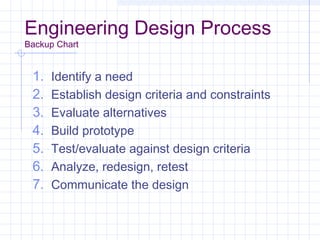

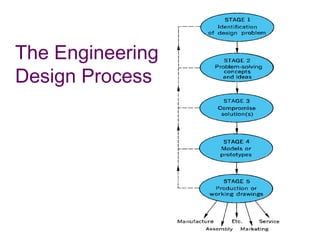

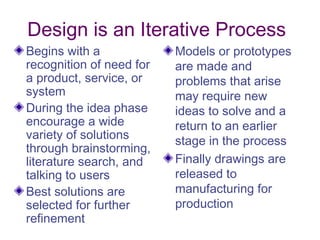

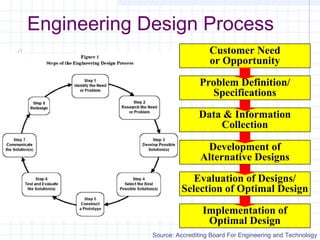

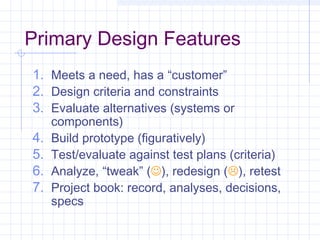

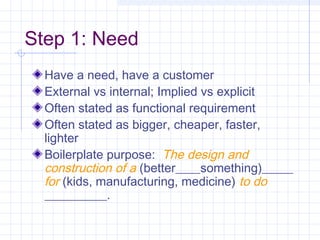

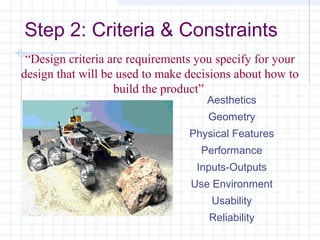

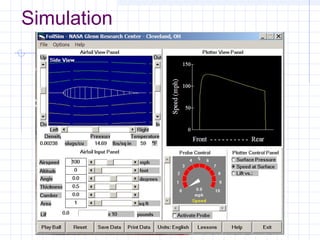

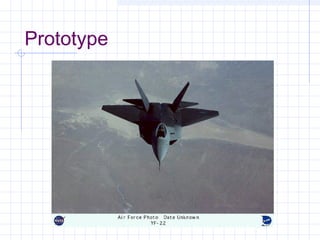

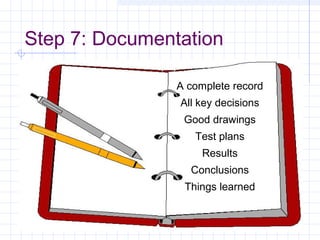

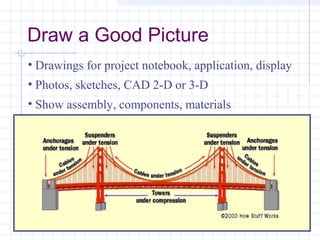

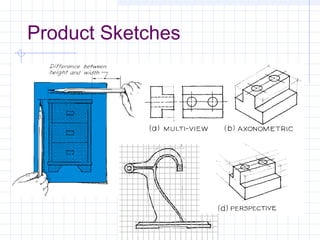

The engineering design process involves 7 primary steps: 1) identifying a need or problem, 2) establishing design criteria and constraints, 3) evaluating alternative design solutions, 4) building prototypes, 5) testing prototypes against criteria, 6) analyzing test results and redesigning as needed, and 7) documenting the final design. The goal is to create a solution that meets customer needs within given constraints through an iterative process of testing and improvement.