This document provides an overview of concepts in engineering design taught by Dr. Yogesh Dewang. It discusses various topics including:

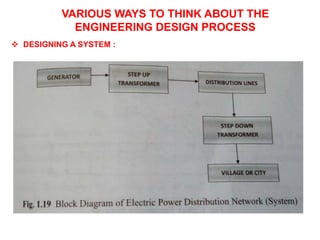

1. Designing a system by breaking it into subsystems and components in an iterative process.

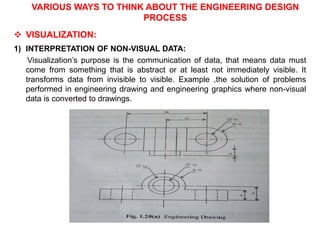

2. Visualization by interpreting non-visual data and producing images.

3. Photography as a science, art, and practice of creating images.

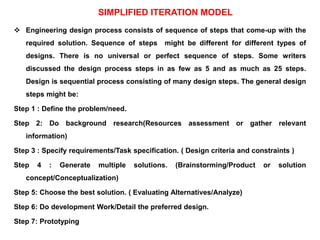

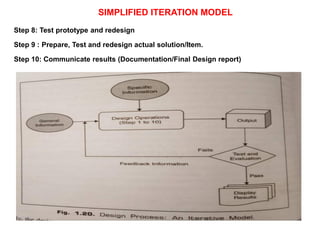

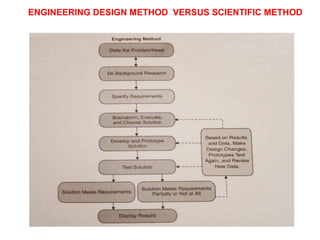

4. Simplified iteration model showing design as an iterative process.

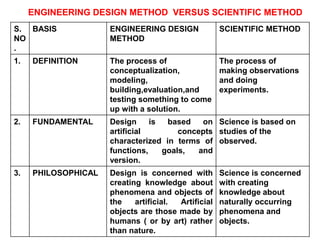

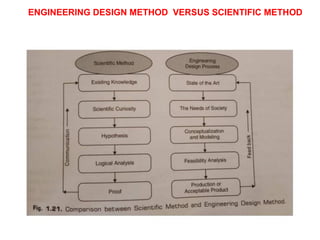

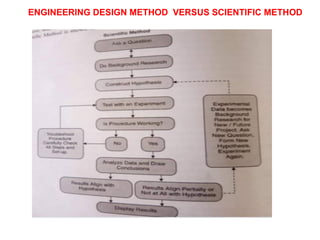

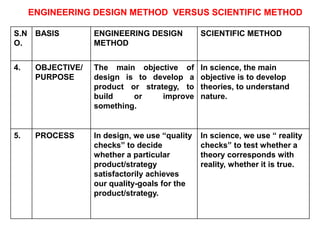

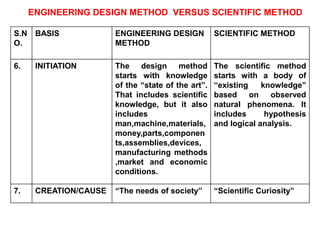

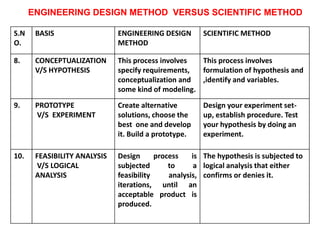

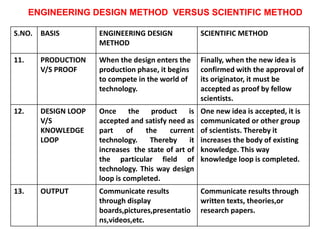

5. Comparison of engineering design method versus scientific method.