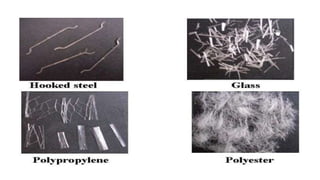

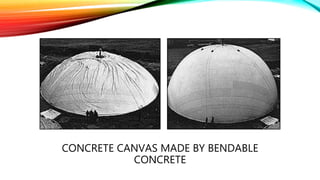

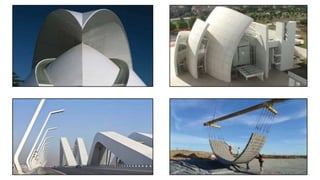

The document discusses bendable or engineered cementitious composite (ECC) concrete. It is a type of fiber-reinforced concrete that is ductile and crack-resistant. ECC concrete uses microfibers, a slick coating on the fibers, fine sand, and superplasticizers. It bends like metal and is stronger and more durable than regular concrete. Structures made of ECC concrete are earthquake and crack resistant. Examples of uses include earthquake-proof buildings, flexible concrete canvases for military use, and more durable bridges and roads.