This document presents a project focused on enhancing the shear strength of reinforced concrete (RC) beams using engineered cementitious composite (ECC) layers. The study outlines the methodology, aims, and objectives, emphasizing the benefits of ECC in terms of strength, durability, and seismic resistance compared to traditional materials. It includes experimental procedures, practical applications in structures like dams and bridges, and future construction guidelines for using ECC in the industry.

![Introduction

• A significant part of the infrastructure is in need of strengthening and rehabilitation.

• This highlights the need to find innovative solutions that offer real advantages over traditional

methods, particularly in terms of performance, simplicity of application, speed of execution,

and ease of handling. [1]

Focus is specifically on structural performance in response to shear loading

11/30/2019 5](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-5-320.jpg)

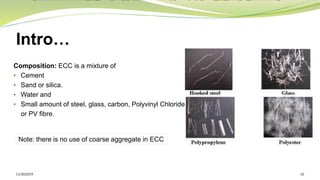

![Intro…

Shear Failure : Shear failure can be defined as a failure that takes place due to

insufficiency of shear resistance available between the materials.

➢ Different techniques are used to upgrade/retrofit the structure

Retrofitting : Retrofitting is the process of addition of new features to older buildings, bridges

etc. Retrofitting reduces the vulnerability of damage of an existing structure during a near future

seismic activity. Retrofitting helps to increase the strength, resistivity and overall lifespan of the

structure.[2]

11/30/2019 6](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-6-320.jpg)

![Intro…

ECC:

Engineered Cementitious composite (ECC) is a class of ultra-ductile fibre invented in early 1990’s by

Dr. Victor Li (University of Michigon) with a design based on micro-mechanics.[3]

ECC has many properties such as

ultra-high tensile strength.

strain hardening behavior.

Strain capacity increase by 3 to 7%.

Reduce corrosion

excellent impact resistance.

11/30/2019 9](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-9-320.jpg)

![Intro…

When RC beam are vulnerable to shear failure they are needed to be strengthened by using

ECC layer externally.

Other works has been done related to this project.

(Kim, S.-W. et all ) [4]

The experimental results show that the use of an ECC layer leads to a substantial increase

in the shear strength and ductility of the RC beams after the peak load.

(Yuan, F. et all) [5]

ECC beams showed better seismic performance in terms of load carrying capacity.

11/30/2019 11](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-11-320.jpg)

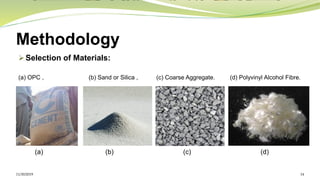

![Cont…

➢Method of Applying ECC layer.[6]

• The procedure consists of the following steps:

• Chisel both sides and bottom of each beam, then clean and wet the sides and

bottom to a standard condition.

• An interface agent will be apply to the sides and bottom of the beams.

• Apply ECC onto the sides and bottom of the beams to the design thickness.

• Cover the beam with a polyethylene sheet to prevent the loss of moisture and cure

for 28 days at room temperature.

11/30/2019 19](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-19-320.jpg)

![Cont…

The Mitaka Dam near Hiroshima was repaired using ECC in 2003.

The surface of the dam was severely damaged, showing evidence of cracks, spalling, and

some water leakage.

A 20 mm-thick layer of ECC was applied by spraying over the 600 m2 surface.[7]

11/30/2019 22](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-22-320.jpg)

![Cont…

The 1 km long Mihara Bridge in Hokkaido, Japan was opened to traffic in 2005. The steel-

reinforced road bed contains nearly 800 m3 of ECC material.

The tensile ductility and tight crack control behaviour of ECC led to a 40% reduction in

material used during construction.[8]

11/30/2019 23](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-23-320.jpg)

![Cont…

The 95 m (312 ft.) Glorio high-rise apartment building in Tokyo contains a total of 54 ECC

beams (two per story) intended to mitigate earthquake damage. The properties of ECC give it

superior properties in seismic resistance applications when compared to ordinary Portland

cement [9]

11/30/2019 24](https://image.slidesharecdn.com/firstproposal-191130131438/85/Engineered-Cementitious-Composite-24-320.jpg)