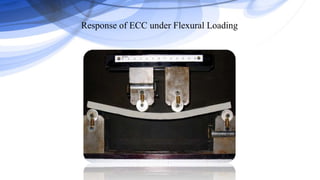

The document presents an overview of bendable concrete, also known as engineered cementitious composite (ECC), highlighting its composition, environmental benefits, applications, and pros and cons. Developed by Victor Li at the University of Michigan, ECC is recognized for its high ductility, reduced carbon emissions, and cost-effectiveness compared to conventional concrete. While it offers enhanced strength and crack resistance, it comes with higher initial costs and requires skilled labor for construction.