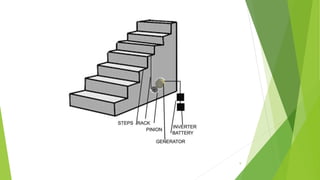

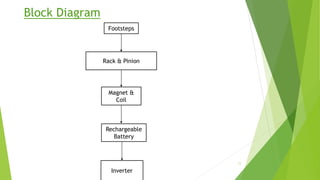

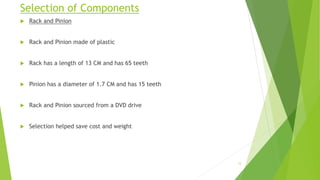

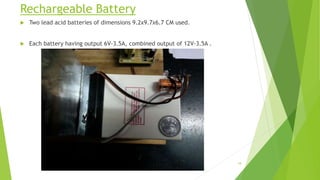

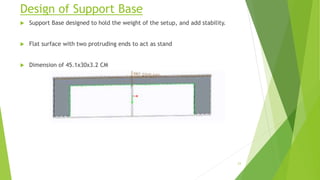

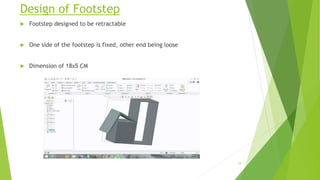

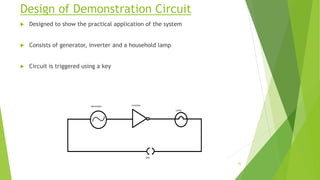

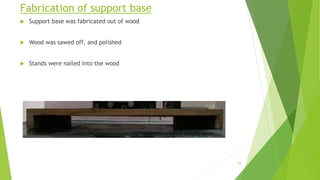

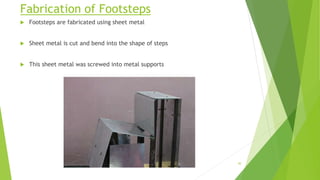

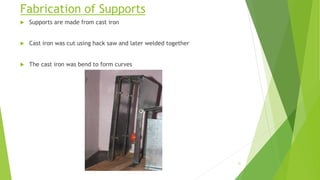

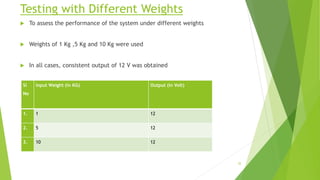

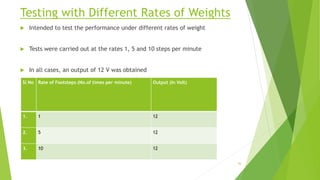

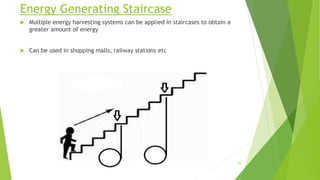

The document outlines a project focused on energy harvesting through footsteps using a rack and pinion mechanism to convert walking energy into electrical power. It details the project's objectives, components, design, fabrication, testing, and potential applications including energy generating staircases and self-illuminating pathways. The system has shown consistent performance under various conditions and offers significant future potential for practical implementations.