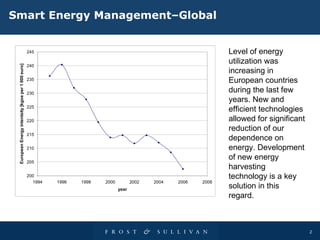

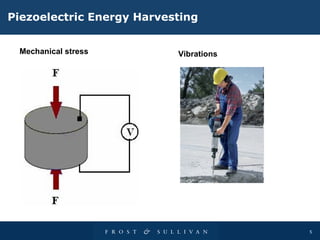

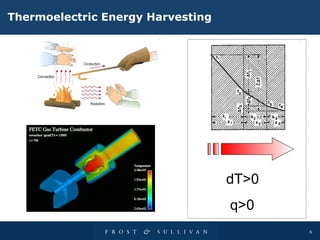

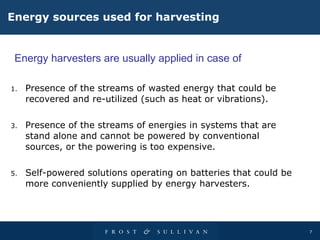

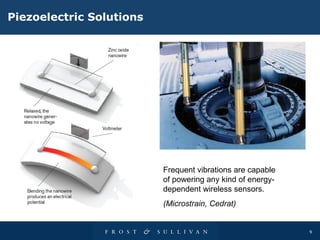

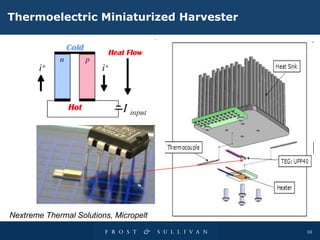

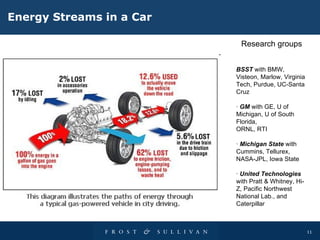

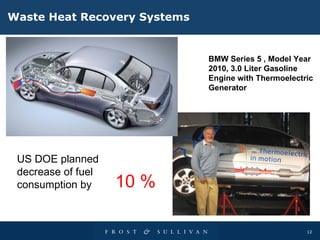

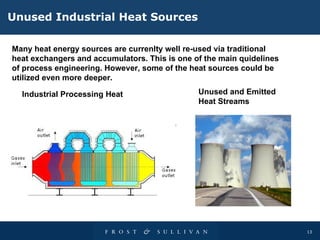

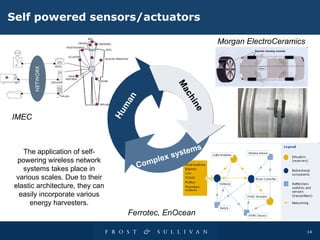

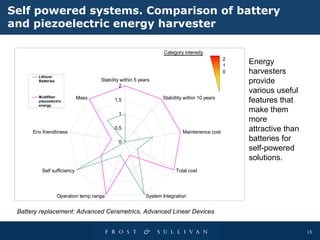

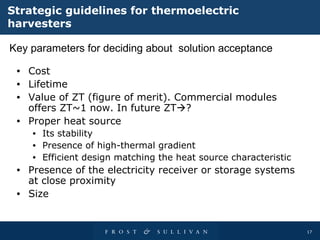

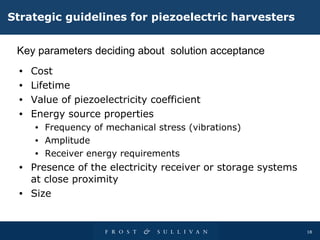

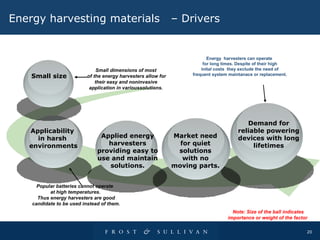

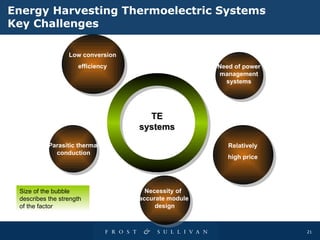

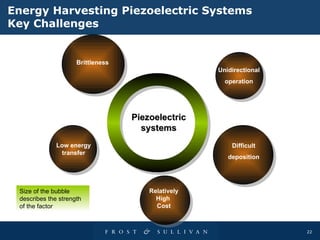

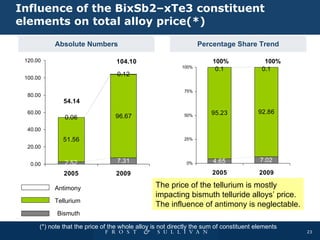

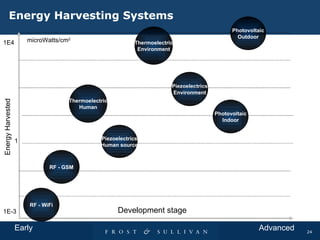

The document discusses advancements in thermal and mechanical energy harvesting technologies, emphasizing their potential to reduce energy dependence and enhance energy utilization in various applications. It highlights different types of energy harvesters, such as piezoelectric and thermoelectric systems, their design considerations, operational challenges, and the importance of materials used for energy harvesting. The document also mentions the growing market need for reliable, long-lasting, and maintenance-free self-powered solutions across multiple industries.