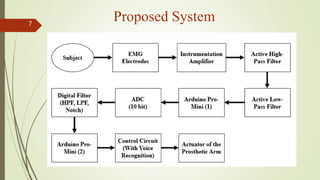

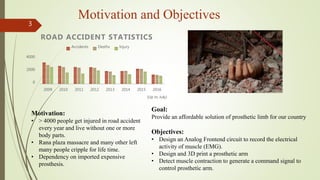

This document summarizes a project to design and implement an EMG-controlled 3D printed prosthetic arm. Key aspects include:

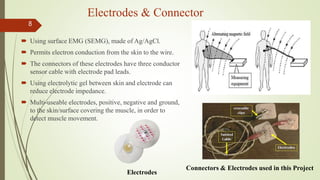

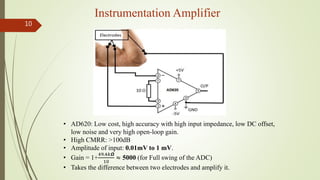

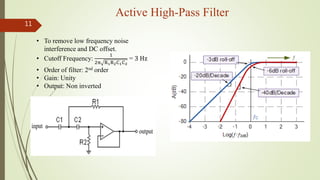

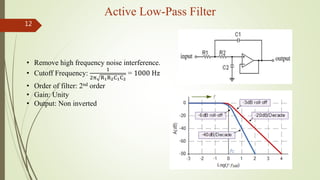

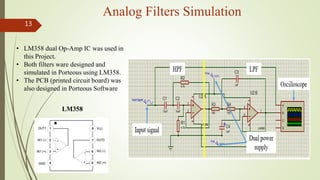

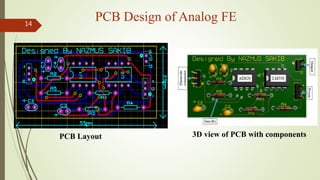

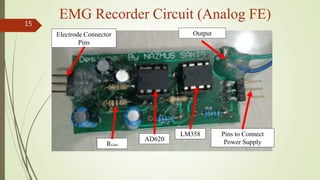

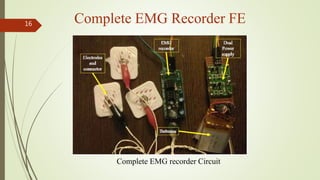

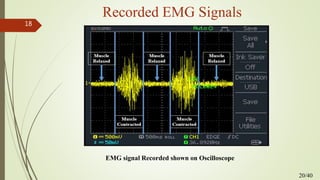

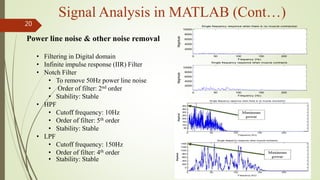

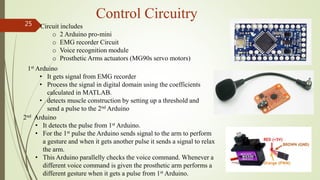

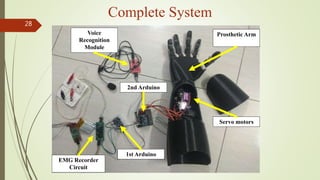

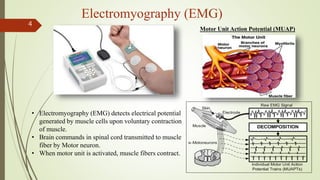

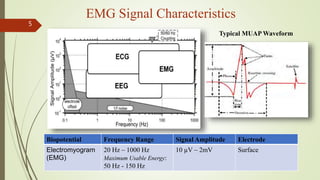

1) An analog front-end circuit was designed to record muscle electrical signals (EMGs) from surface electrodes and filter the signals.

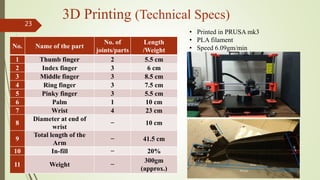

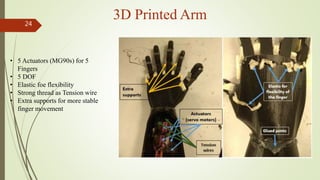

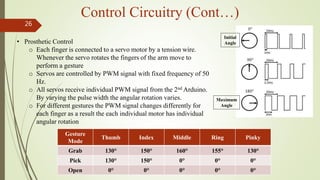

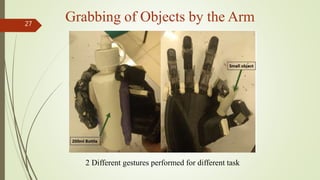

2) A prosthetic arm design was 3D printed with 5 fingers and 5 degrees of freedom. Servo motors control finger movement.

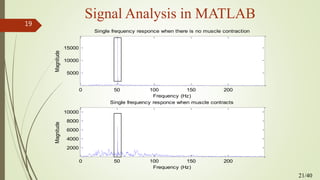

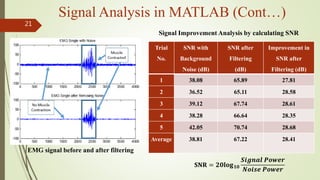

3) EMG signals are analyzed in MATLAB and used to detect muscle contractions and control the prosthetic arm motions in real-time using an Arduino microcontroller.

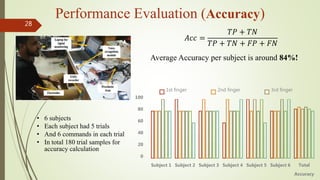

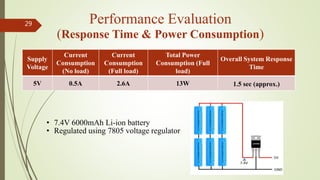

4) Testing showed the system achieved over 84% accuracy in gesture recognition with a response time of 1.5 seconds using a

![6

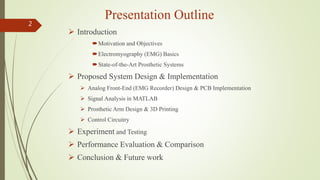

Currently Available Prosthetic Systems*

Touch Bioinics Open Hand Project Bebionics

Price range: USD 10K

Products:

• i-limb revolution

• i-limb ultra

• i-limb digits

• livingskin

• Price range: USD 1K

• They are using 3D

printer technology

• Price range:

Between USD 11-

60K.

• Most advanced

prosthetic

technology

• Human like hand

movement system.

Price range: USD 6K

Products:

• Brunel Hand 2.0

• Hero Arm

Open Bionics

*Ref: [2]-[5]](https://image.slidesharecdn.com/emgpresentation-200130144050/85/EMG-controlled-Prosthetic-Arm-6-320.jpg)