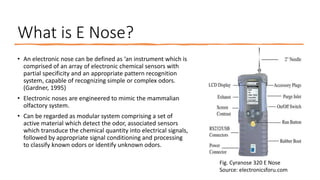

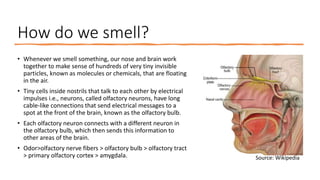

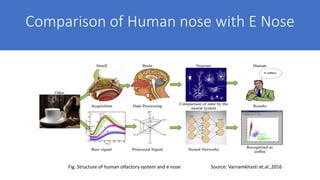

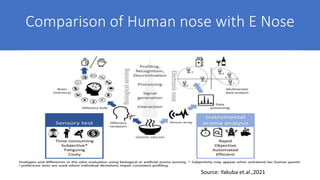

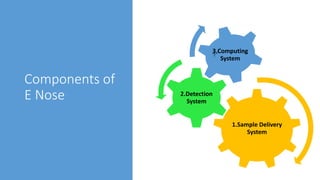

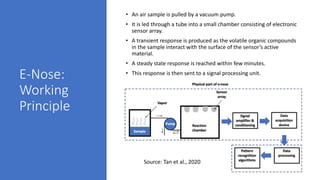

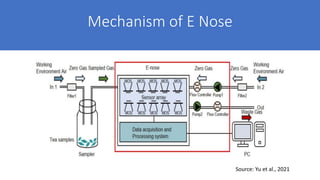

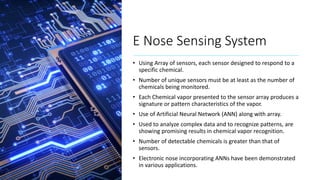

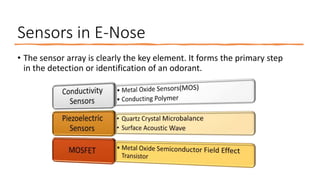

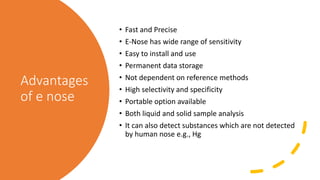

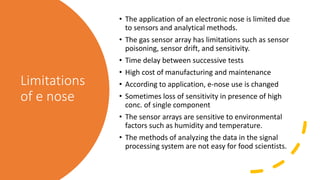

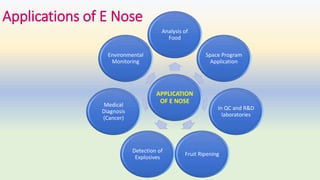

This document discusses the electronic nose (e-nose), a device designed to mimic the human olfactory system for detecting and classifying odors and volatile compounds in various applications, particularly in food quality assessment. It outlines the components, functioning, advantages, and limitations of the e-nose, while also providing examples of its applications in food analysis for meat, oils, tea, and dairy products. The conclusion highlights the potential for e-nose technology to improve food safety and quality control in the future.