BP_Waterline Hydrostatic

•Download as DOCX, PDF•

2 likes•1,974 views

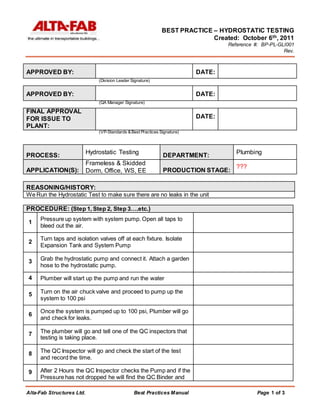

This document outlines best practices for hydrostatic testing plumbing systems. It describes a 10 step process for conducting hydrostatic tests, which involves pressurizing the system to 100 psi using a hydrostatic pump and garden hose, checking for leaks over 2 hours, and documenting the results. The goals of hydrostatic testing are to check for any leaks in the plumbing unit and ensure it meets pressure requirements before final approval. Materials used include a hydrostatic pump, and references may include photos, drawings, tables, or engineering details.

Report

Share

Report

Share

Recommended

Piping presentation (master)

Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid

Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of Piping Design (or Piping Engineering). Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process.

"Piping" sometimes refers to Piping Design, the detailed specification of the physical piping layout within a process plant or commercial building. In earlier days, this was sometimes called Drafting, Technical drawing, Engineering Drawing, and Design but is today commonly performed by Designers who have learned to use automated Computer Aided Drawing / Computer Aided Design (CAD) software

Piping Training course-How to be an Expert in Pipe & Fittings for Oil & Gas c...

Course Description

Piping a must know skill to work in Oil & Gas and similar Process Industries.

Oil and Gas industry is become a very competitive in the current time. Getting right mentor and right exposer within industry is difficult. With limited training budget spent by company on employee training, it is difficult to acquire the knowledge to success.

Knowing cross-functional skill give you an edge over others in your career success.

This course design based on years of field experience to ensure student will comprehend technical details easily and enjoy overall journey.

Learn in detail every aspect of Pipe & Pipe Fittings used in process industry

•Different types of Pipe, Pipe fittings (Elbow, Tee, reducers, Caps etc.), Flanges, Gaskets, Branch Connection, Bolting materials

•Materials (Metal-Carbon Steel, Stainless Steel, Alloy Steel etc. Non-Metal- PVC/VCM, HDPE, GRE-GRP etc.)

•Manufacturing methods

•Heat treatment requirements

•Inspection and Testing requirements (Non Destructive Testing, Mechanical & Chemical testing)

•Dimensions & Markings requirements

•Code & Standard used in piping

Content and Overview

With 2 hours of content including 30 lectures & 8 Quizzes, this course cover every aspect of Pipe, Pipe fittings, flanges, gaskets, branch connections and bolting material used in Process Piping.

This Course is divided in three parts.

1st part of the course covers fundamental of process industries. In this Part, you will learn about fundamental process piping. You will also learn about Code, Standard & Specification used in process industries.

2nd part cover various types of material used in process industries. In this part, you will learn about Metallic and Non-Metallic material used to manufacture pipe and other piping components.

3rd parts covers in detail about pipe and piping components used in Process piping. In this part we will learn about Industry terminology of Piping components, types of industrial material grade used in manufacturing and entire manufacturing process of these components. You will learn about different manufacturing methods, Heat treatment requirements, Destructive and Non-destructive testing, Visual & Dimensional inspection and Product marking requirements.

Upon completion, you will be able to use this knowledge direct on your Job and you can easily answer any interview question on pipe & fittings.

TPI - Example Report.

An example of a TPI vendor report. The details listed are only populated as an example.

Recommended

Piping presentation (master)

Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid

Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of Piping Design (or Piping Engineering). Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process.

"Piping" sometimes refers to Piping Design, the detailed specification of the physical piping layout within a process plant or commercial building. In earlier days, this was sometimes called Drafting, Technical drawing, Engineering Drawing, and Design but is today commonly performed by Designers who have learned to use automated Computer Aided Drawing / Computer Aided Design (CAD) software

Piping Training course-How to be an Expert in Pipe & Fittings for Oil & Gas c...

Course Description

Piping a must know skill to work in Oil & Gas and similar Process Industries.

Oil and Gas industry is become a very competitive in the current time. Getting right mentor and right exposer within industry is difficult. With limited training budget spent by company on employee training, it is difficult to acquire the knowledge to success.

Knowing cross-functional skill give you an edge over others in your career success.

This course design based on years of field experience to ensure student will comprehend technical details easily and enjoy overall journey.

Learn in detail every aspect of Pipe & Pipe Fittings used in process industry

•Different types of Pipe, Pipe fittings (Elbow, Tee, reducers, Caps etc.), Flanges, Gaskets, Branch Connection, Bolting materials

•Materials (Metal-Carbon Steel, Stainless Steel, Alloy Steel etc. Non-Metal- PVC/VCM, HDPE, GRE-GRP etc.)

•Manufacturing methods

•Heat treatment requirements

•Inspection and Testing requirements (Non Destructive Testing, Mechanical & Chemical testing)

•Dimensions & Markings requirements

•Code & Standard used in piping

Content and Overview

With 2 hours of content including 30 lectures & 8 Quizzes, this course cover every aspect of Pipe, Pipe fittings, flanges, gaskets, branch connections and bolting material used in Process Piping.

This Course is divided in three parts.

1st part of the course covers fundamental of process industries. In this Part, you will learn about fundamental process piping. You will also learn about Code, Standard & Specification used in process industries.

2nd part cover various types of material used in process industries. In this part, you will learn about Metallic and Non-Metallic material used to manufacture pipe and other piping components.

3rd parts covers in detail about pipe and piping components used in Process piping. In this part we will learn about Industry terminology of Piping components, types of industrial material grade used in manufacturing and entire manufacturing process of these components. You will learn about different manufacturing methods, Heat treatment requirements, Destructive and Non-destructive testing, Visual & Dimensional inspection and Product marking requirements.

Upon completion, you will be able to use this knowledge direct on your Job and you can easily answer any interview question on pipe & fittings.

TPI - Example Report.

An example of a TPI vendor report. The details listed are only populated as an example.

Maintenance report on Circulating Water Pump (CWP) Overhauling

Maintenance report on Circulating Water Pump (CWP) OverhaulingSummit Power International https://summitpowerinternational.com/

Haripur Combined Cycle Power Plant have two cooling water pump (CWP-A/B) each 50% capacity. According to schedule maintenance plan each pump is overhauled after 16,000 running hours.

The pump suction is from river water to discharge to water boxes of steam condenser. It’s a vertical shaft, 1350 discharge bore mixed flow pump. It’s driven by an 1100 KW vertically mounted motor with a rated full load rpm of 494. Rated flow rate of the pump is 18, 600 m3/hr.

Before the overhauling CWP-A, NDE side vibration of motor as being monitored was too high for its sound performance. Vertical vibration data at NDE was measured as high as 6.3 mm/sec which was way alarming.

Suspected regions were out-clearances of bearings and wear-rings. O & M came to a decision for complete overhauling of the pump which started on November 27, 2011 and was completed on December 01, 2011.

Piping and Vessels Flushing and Cleaning Procedure

Ammonia Plant Technology

Pre-Commissioning Best Practices

Piping and Vessels Flushing and Cleaning Procedure

CONTENTS

1 Scope

2 Aim/purpose

3 Responsibilities

4 Procedure

4.1 Main cleaning methods

4.1.1 Mechanical cleaning

4.1.2 Cleaning with air

4.1.3 Cleaning with steam (for steam networks only)

4.1.4 Cleaning with water

4.2 Choice of the cleaning method

4.3 Cleaning preparation

4.4 Protection of the devices included in the network

4.5 Protection of devices in the vicinity of the network

4.6 Water flushing procedure

4.6.1 Specific problems of water flushing

4.6.2 Preparation for water flushing

4.6.3 Performing a water flush

4.6.4 Cleanliness criteria

4.7 Air blowing procedure

4.7.1 Specific problems of air blowing

4.7.2 Preparation for air blowing

4.7.3 Performing air blowing

4.7.4 Cleanliness checks

4.8 Steam blowing procedure

4.8.1 Specific problems of steam blowing

4.8.2 Preparation for steam blowing

4.8.3 Performing steam blowing

4.8.4 Cleanliness checks

4.9 Chemical cleaning procedure

4.9.1 Specific problems of cleaning with a chemical solution

4.9.2 Preparation for chemical cleaning

4.9.3 Performing a chemical cleaning

4.9.4 Cleanliness criteria

4.10 Re-assembly - general guideline

4.11 Preservation of flushed piping

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...Society of Petroleum Engineers

Coiled tubing is a unique fluid and tool conveyance means used to intervene throughout the entire well lifetime. Its flexibility of use is certainly one of the largest in the oil-and-gas industry, ranging from logging to stimulation to cleanout and even drilling. However, for the longest time, it was only seen as a rudimentary fluid conveyance system, despite its capability to service any well deviation.

With the development of instrumented tools for downhole point measurements and the use of fiber optics for distributed sensing, the recent advent of coiled tubing real-time monitoring has completely transformed this image. The access to live wellbore information—such as pressure, temperature, or flow—along with accurate depth control thanks to casing collar locator and gamma ray sensors have greatly enhanced fluid placement. Meanwhile, the ability to monitor the load, torque, and accelerations the bottomhole assembly is subjected to significantly improves the performance and possibility to use and manipulate downhole tools. Thanks to real-time monitoring, a whole new realm of optimization possibility was discovered.

This lecture describes the various real-time measurements that are available today during coiled tubing interventions and how they can be used to provide the industry with faster, safer, and more efficient operations while maximizing return on investment. A wide range of applications and examples will be discussed. Through them, one will be able to appreciate how coiled tubing has now entered a new era where the limits of operational optimization still have not been reached.

Eng handbook crosby pressure relief valve engineering handbook

Reference is made to the ASME Boiler and Pressure Vessel Code, Section VIII, Pressure Vessels. The information in this handbook is not to be used for the application of overpressure protection to power boilers and nuclear power plant components which are addressed in the ASEM Boiler and Pressure Vessel Code Section I.

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Process piping fundamentals, codes and standards module 1

Fundamentals of piping explained very well in this article. very useful for beginners

01 General Control Valves Training.

Control Valves types, control valves characterstics, affects on control valves due to various process fluctuations or cavitations or flashing and remidies.The model datasheets also included.

Pump api 675 presentation

Positive Displacement Pumps—

Controlled Volume for Petroleum, Chemical, and Gas Industry Services

Technical Requirements

SFCXX1 - SFCXX2 Air Flow Testing Report

In the first half of this year I was asked to investigate the potential passive air flow on two odour skid's. It was thought that the current media in the tank's could be changed out with more economical product. Before this could be determined the passive flows needed to be checked before and after the extraction fan.

More Related Content

What's hot

Maintenance report on Circulating Water Pump (CWP) Overhauling

Maintenance report on Circulating Water Pump (CWP) OverhaulingSummit Power International https://summitpowerinternational.com/

Haripur Combined Cycle Power Plant have two cooling water pump (CWP-A/B) each 50% capacity. According to schedule maintenance plan each pump is overhauled after 16,000 running hours.

The pump suction is from river water to discharge to water boxes of steam condenser. It’s a vertical shaft, 1350 discharge bore mixed flow pump. It’s driven by an 1100 KW vertically mounted motor with a rated full load rpm of 494. Rated flow rate of the pump is 18, 600 m3/hr.

Before the overhauling CWP-A, NDE side vibration of motor as being monitored was too high for its sound performance. Vertical vibration data at NDE was measured as high as 6.3 mm/sec which was way alarming.

Suspected regions were out-clearances of bearings and wear-rings. O & M came to a decision for complete overhauling of the pump which started on November 27, 2011 and was completed on December 01, 2011.

Piping and Vessels Flushing and Cleaning Procedure

Ammonia Plant Technology

Pre-Commissioning Best Practices

Piping and Vessels Flushing and Cleaning Procedure

CONTENTS

1 Scope

2 Aim/purpose

3 Responsibilities

4 Procedure

4.1 Main cleaning methods

4.1.1 Mechanical cleaning

4.1.2 Cleaning with air

4.1.3 Cleaning with steam (for steam networks only)

4.1.4 Cleaning with water

4.2 Choice of the cleaning method

4.3 Cleaning preparation

4.4 Protection of the devices included in the network

4.5 Protection of devices in the vicinity of the network

4.6 Water flushing procedure

4.6.1 Specific problems of water flushing

4.6.2 Preparation for water flushing

4.6.3 Performing a water flush

4.6.4 Cleanliness criteria

4.7 Air blowing procedure

4.7.1 Specific problems of air blowing

4.7.2 Preparation for air blowing

4.7.3 Performing air blowing

4.7.4 Cleanliness checks

4.8 Steam blowing procedure

4.8.1 Specific problems of steam blowing

4.8.2 Preparation for steam blowing

4.8.3 Performing steam blowing

4.8.4 Cleanliness checks

4.9 Chemical cleaning procedure

4.9.1 Specific problems of cleaning with a chemical solution

4.9.2 Preparation for chemical cleaning

4.9.3 Performing a chemical cleaning

4.9.4 Cleanliness criteria

4.10 Re-assembly - general guideline

4.11 Preservation of flushed piping

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...Society of Petroleum Engineers

Coiled tubing is a unique fluid and tool conveyance means used to intervene throughout the entire well lifetime. Its flexibility of use is certainly one of the largest in the oil-and-gas industry, ranging from logging to stimulation to cleanout and even drilling. However, for the longest time, it was only seen as a rudimentary fluid conveyance system, despite its capability to service any well deviation.

With the development of instrumented tools for downhole point measurements and the use of fiber optics for distributed sensing, the recent advent of coiled tubing real-time monitoring has completely transformed this image. The access to live wellbore information—such as pressure, temperature, or flow—along with accurate depth control thanks to casing collar locator and gamma ray sensors have greatly enhanced fluid placement. Meanwhile, the ability to monitor the load, torque, and accelerations the bottomhole assembly is subjected to significantly improves the performance and possibility to use and manipulate downhole tools. Thanks to real-time monitoring, a whole new realm of optimization possibility was discovered.

This lecture describes the various real-time measurements that are available today during coiled tubing interventions and how they can be used to provide the industry with faster, safer, and more efficient operations while maximizing return on investment. A wide range of applications and examples will be discussed. Through them, one will be able to appreciate how coiled tubing has now entered a new era where the limits of operational optimization still have not been reached.

Eng handbook crosby pressure relief valve engineering handbook

Reference is made to the ASME Boiler and Pressure Vessel Code, Section VIII, Pressure Vessels. The information in this handbook is not to be used for the application of overpressure protection to power boilers and nuclear power plant components which are addressed in the ASEM Boiler and Pressure Vessel Code Section I.

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Process piping fundamentals, codes and standards module 1

Fundamentals of piping explained very well in this article. very useful for beginners

01 General Control Valves Training.

Control Valves types, control valves characterstics, affects on control valves due to various process fluctuations or cavitations or flashing and remidies.The model datasheets also included.

Pump api 675 presentation

Positive Displacement Pumps—

Controlled Volume for Petroleum, Chemical, and Gas Industry Services

Technical Requirements

What's hot (20)

Maintenance report on Circulating Water Pump (CWP) Overhauling

Maintenance report on Circulating Water Pump (CWP) Overhauling

Piping and Vessels Flushing and Cleaning Procedure

Piping and Vessels Flushing and Cleaning Procedure

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...

Coiled Tubing Real-Time Monitoring: A New Era of Well Intervention and Worko...

Eng handbook crosby pressure relief valve engineering handbook

Eng handbook crosby pressure relief valve engineering handbook

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Hydrostatic pressure testing of PE pipelines (handbook) as per EN805

Process piping fundamentals, codes and standards module 1

Process piping fundamentals, codes and standards module 1

Similar to BP_Waterline Hydrostatic

SFCXX1 - SFCXX2 Air Flow Testing Report

In the first half of this year I was asked to investigate the potential passive air flow on two odour skid's. It was thought that the current media in the tank's could be changed out with more economical product. Before this could be determined the passive flows needed to be checked before and after the extraction fan.

Tab Fire Pump Testing

Great information regarding fire pump testing - including a sample safety report.

Mills Park Consent Order

A representative for the Florida Department of Environmental Protection told Bungalower that as a result of the previous spills, they have entered into a Consent Order, attached below, with Mills Park as of September 26, 2019. The Department is making them complete a list of improvements to the lift station by February 23, 2020. If those improvements are not carried out, penalties will be put into place.

IRJET- Design Modifications in Cryogenic Pressure Relief Valve to Elimina...

https://www.irjet.net/archives/V6/i8/IRJET-V6I8141.pdf

Validating a Relief Device Stability Model

In November 2011, Hydrocarbon Processing published a paper that documented a method to determine if relief devices were susceptible to chatter. Other methods are being developed to determine the chances of chatter for a specific installation; however, the model discussed in the published paper is the only screening method that places the relief devices into two categories: (1) those installations that may chatter and (2) those installations that need no further review. The goal of any experimental comparison is that it will error on the side of predicting chatter, but will be reliable enough to screen valves. Since the publication of that article, the Oil & Gas industry has continued to struggle with the issue of relief device stability so much so that API delayed issuance of API STD 520 Part II Sizing, Selection, and Installation of Pressure-Relieving Devices in Refineries-Part II, Installation. This paper compares instances of known chatter to research conducted by API, and uses this comparison to evaluate the model. Thus far, based on research and all acquired information, the method predicted all instances of chatter known to the authors.

Practical task 1 pneumatik june 2018

PRACTICAL TASK BASIC PNEUMATIC CIRCUIT FOR POLYTECHNIC Syllabus REQUIREMENT

Similar to BP_Waterline Hydrostatic (20)

Hazard operability study - in Industires and plant

Hazard operability study - in Industires and plant

IRJET- Design Modifications in Cryogenic Pressure Relief Valve to Elimina...

IRJET- Design Modifications in Cryogenic Pressure Relief Valve to Elimina...

More from Scott Nunn

More from Scott Nunn (13)

BP_Waterline Hydrostatic

- 1. BEST PRACTICE – HYDROSTATIC TESTING Created: October 6th, 2011 Reference #: BP-PL-GLI001 Rev. Alta-Fab Structures Ltd. Best Practices Manual Page 1 of 3 APPROVED BY: DATE: (Division Leader Signature) APPROVED BY: DATE: (QA Manager Signature) FINAL APPROVAL FOR ISSUE TO PLANT: DATE: (VP-Standards & Best Practices Signature) PROCESS: Hydrostatic Testing DEPARTMENT: Plumbing APPLICATION(S): Frameless & Skidded Dorm, Office, WS, EE PRODUCTION STAGE: ??? REASONING/HISTORY: We Run the Hydrostatic Test to make sure there are no leaks in the unit PROCEDURE: (Step 1, Step 2, Step 3….etc.) 1 Pressure up system with system pump. Open all taps to bleed out the air. 2 Turn taps and isolation valves off at each fixture. Isolate Expansion Tank and System Pump 3 Grab the hydrostatic pump and connect it. Attach a garden hose to the hydrostatic pump. 4 Plumber will start up the pump and run the water 5 Turn on the air chuck valve and proceed to pump up the system to 100 psi 6 Once the system is pumped up to 100 psi, Plumber will go and check for leaks. 7 The plumber will go and tell one of the QC inspectors that testing is taking place. 8 The QC Inspector will go and check the start of the test and record the time. 9 After 2 Hours the QC Inspector checks the Pump and if the Pressure has not dropped he will find the QC Binder and

- 2. BEST PRACTICE – HYDROSTATIC TESTING Created: October 6th, 2011 Reference #: BP-PL-GLI001 Rev. Alta-Fab Structures Ltd. Best Practices Manual Page 2 of 3 fill out the Hydrostatic Testing Portion in the Plumbing section. If the Pressure has dropped or failed the QC Inspector will find the Plumber and let him know about the Pressure. The Plumber will then re-check for Leaks If there are Leaks the Plumber will Fix them up and re-start the Hydrostatic Test. 10 Once the QC Inspector is finished filling out the paper work he will tell the Plumber that it is finished. MATERIALS: Insert in bullet form what materials are used in this Best Practice. Hydrostatic Pump REFERENCE(S): Photo, Drawing, Table, Engineering Details, Code Insert in bullet form what reference material you will be using below for the Best Practice. Reviewed by:_________________________ (Please Print) Position: _________________________ DEPARTMENT EMPLOYEE SIGN-OFF Print Name Signature Date Reviewed

- 3. BEST PRACTICE – HYDROSTATIC TESTING Created: October 6th, 2011 Reference #: BP-PL-GLI001 Rev. Alta-Fab Structures Ltd. Best Practices Manual Page 3 of 3