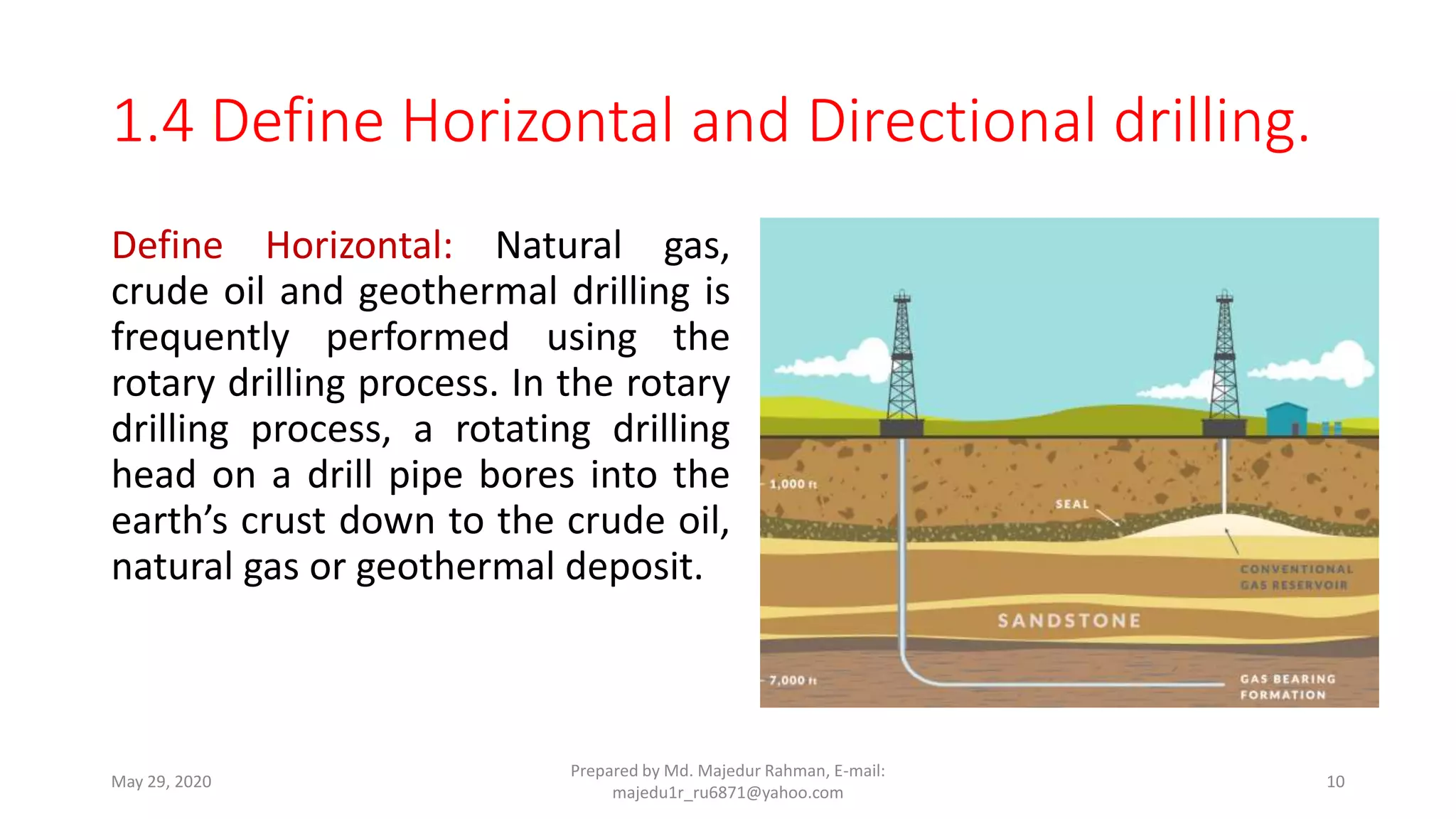

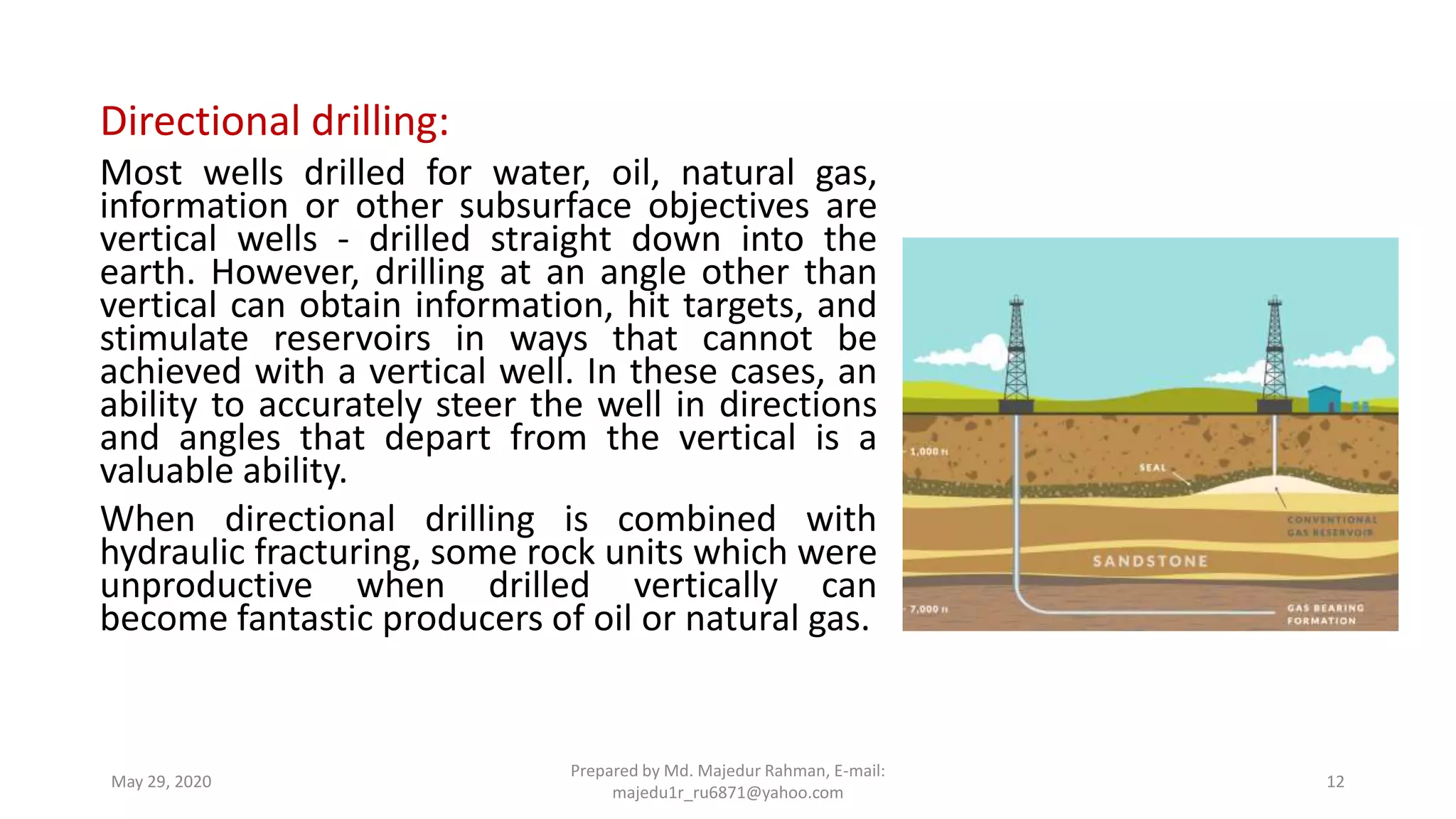

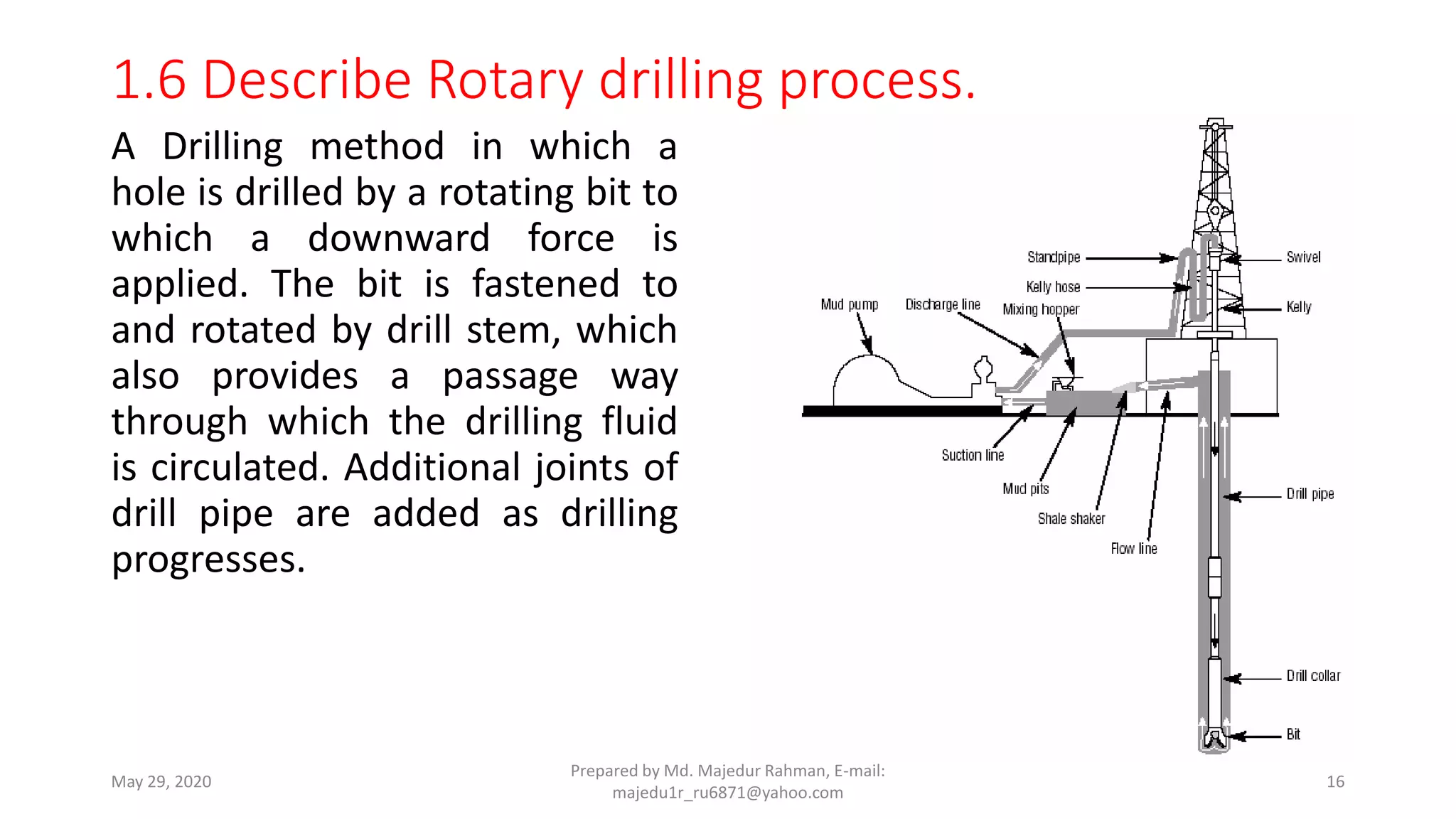

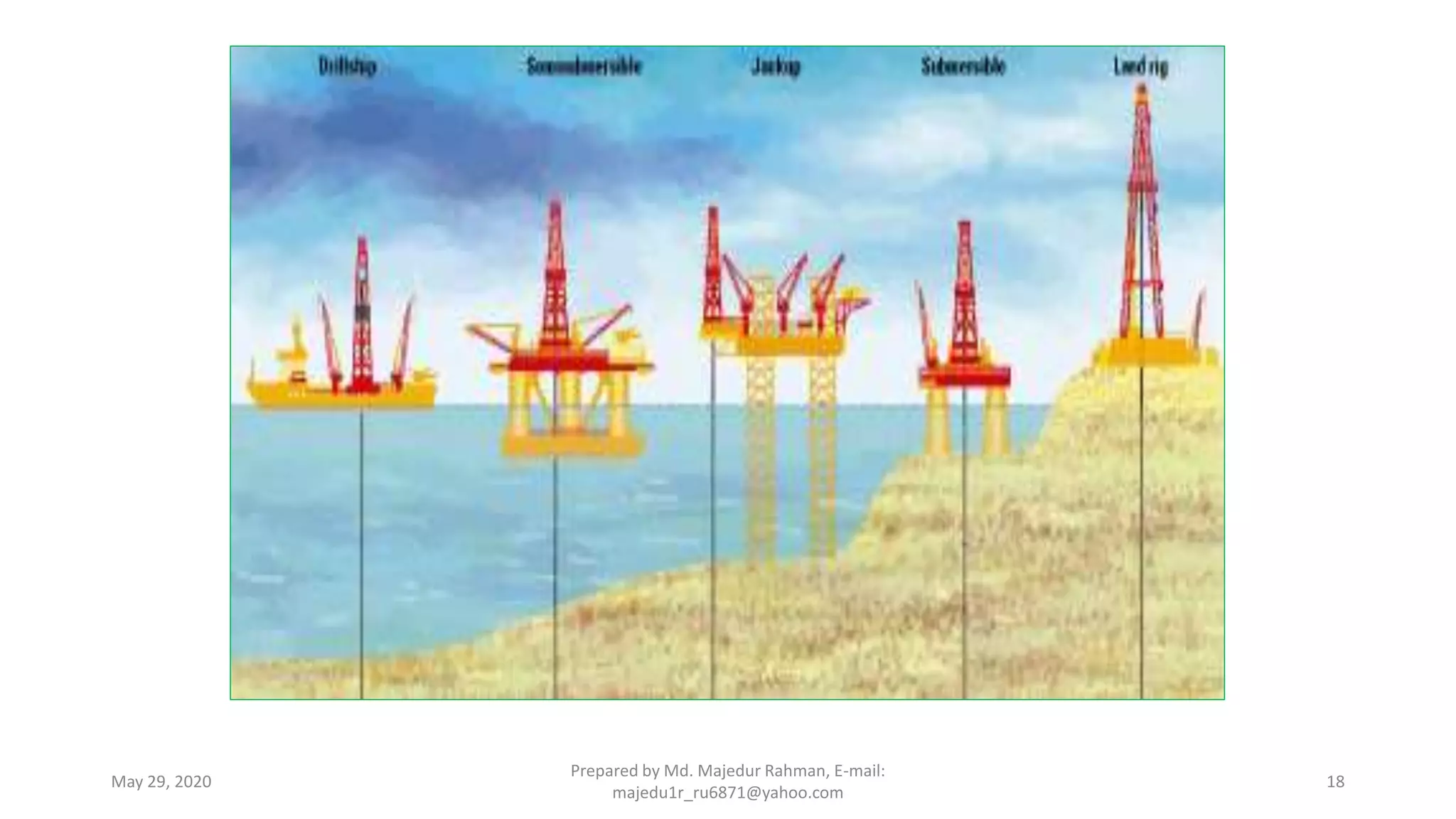

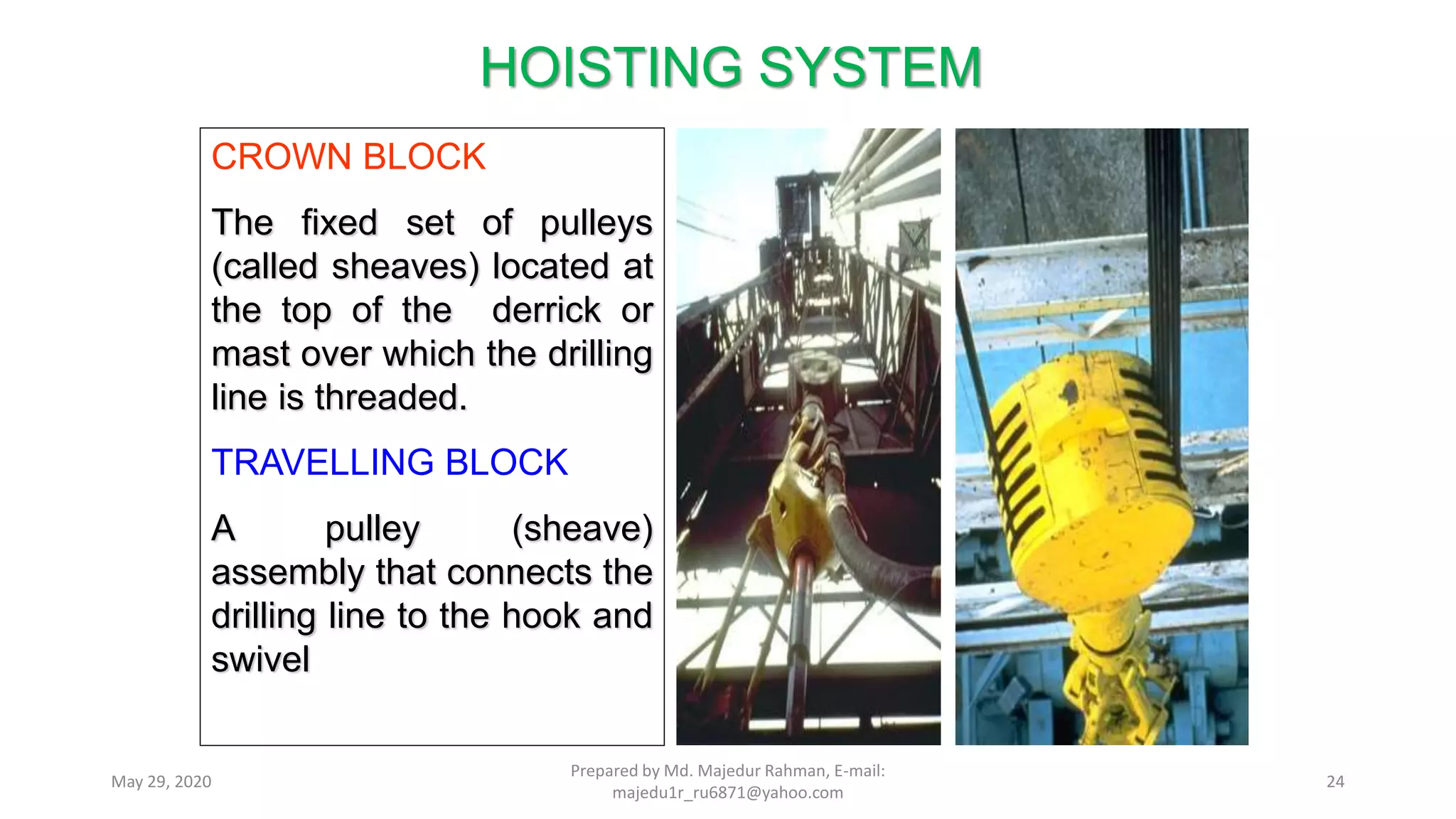

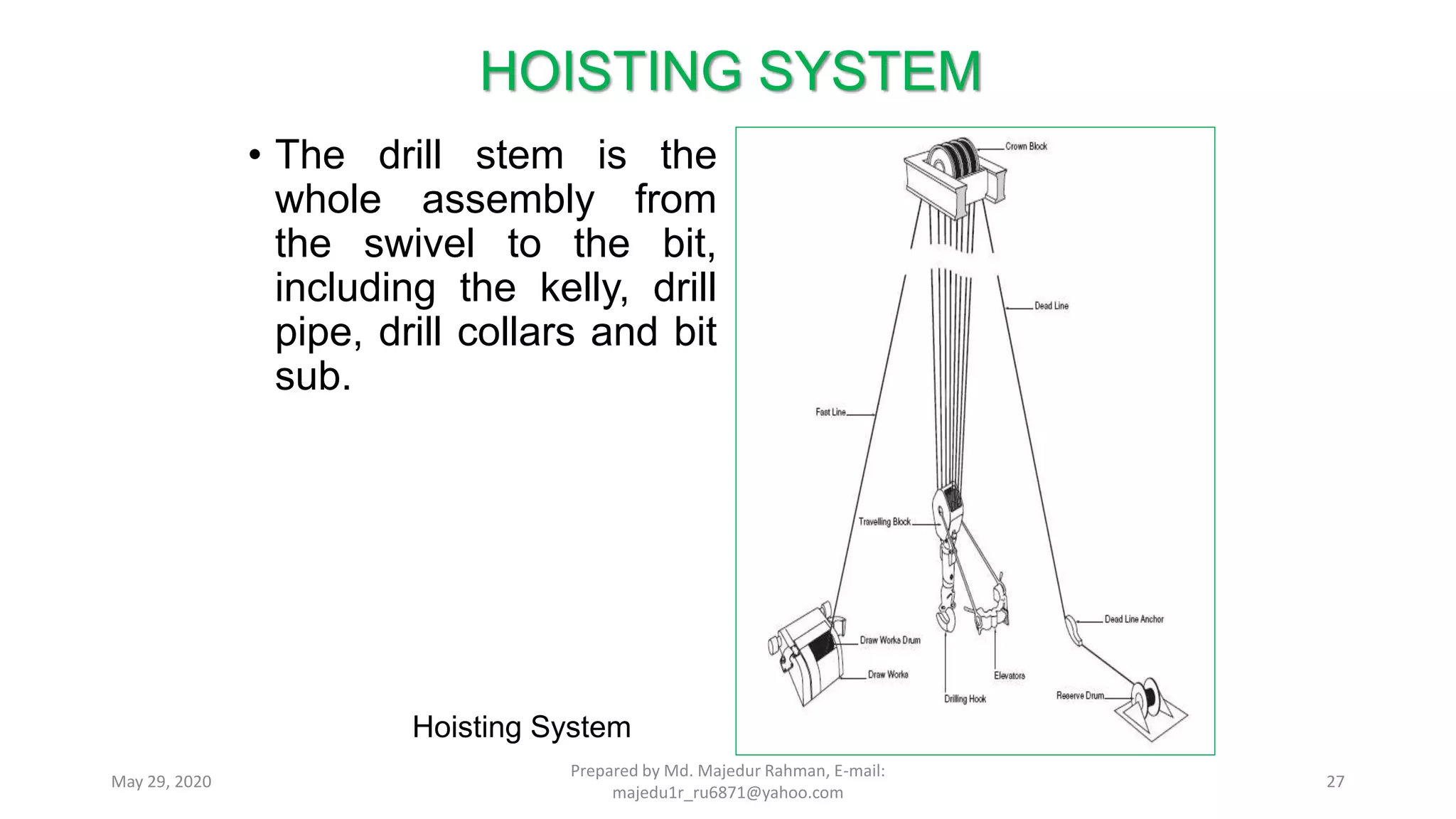

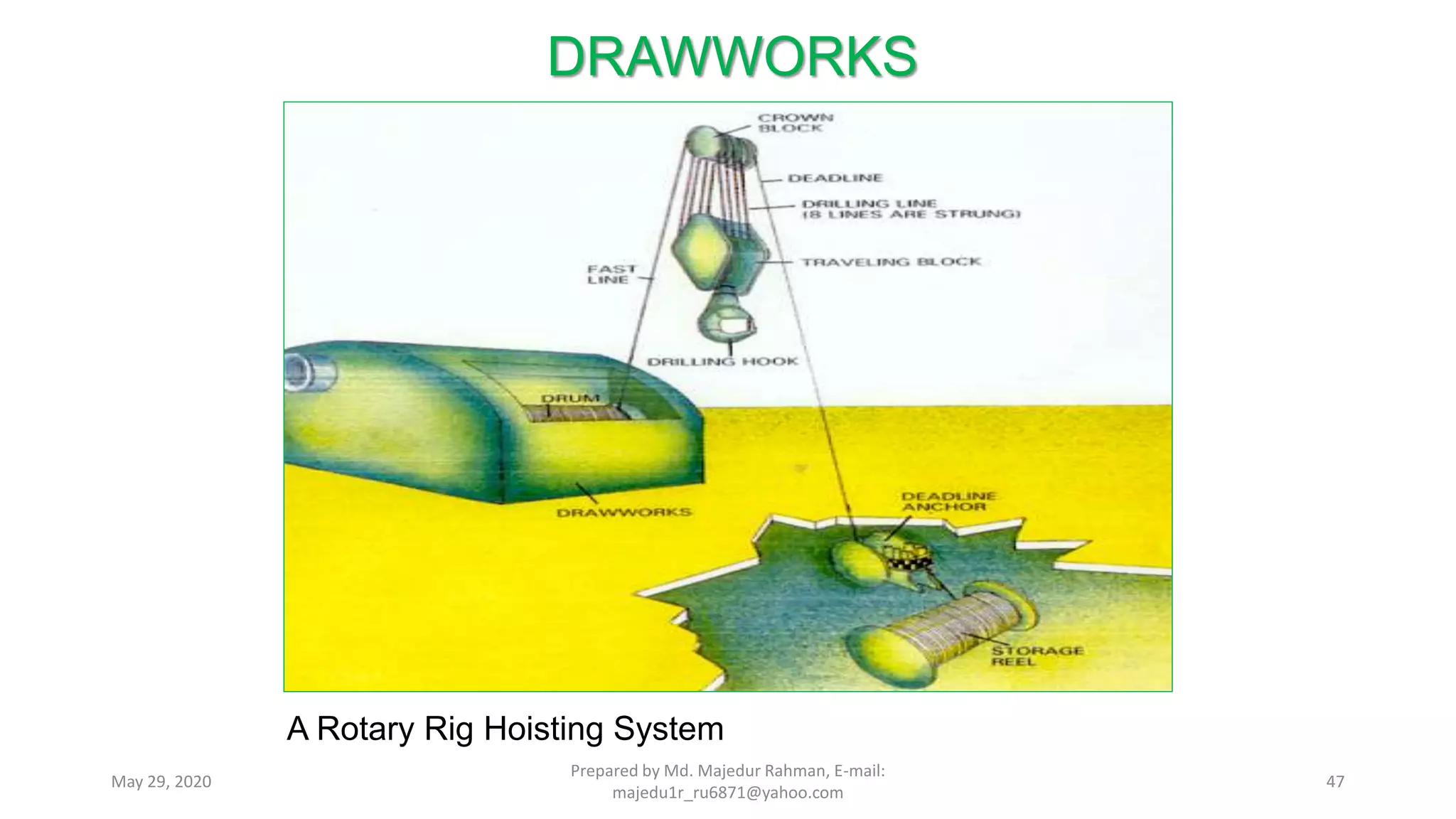

The document provides an overview of a petroleum well design and completion course at Bogura Polytechnic Institute, focusing on the knowledge, skills, and attitudes necessary for well planning, design, and completion. It covers key topics such as well drilling processes, types of drilling methods, and drilling rigs, as well as the technological aspects of rotary and cable tool drilling. Additionally, it highlights the significance of directional and horizontal drilling in optimizing oil and gas extraction.