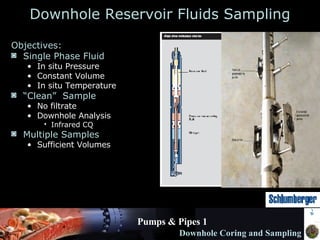

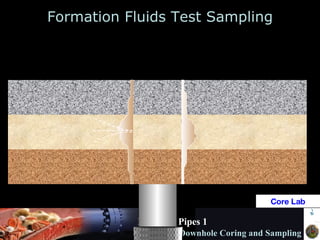

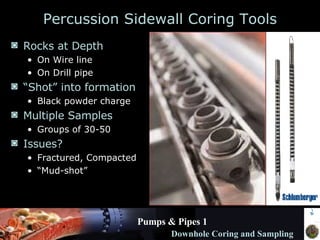

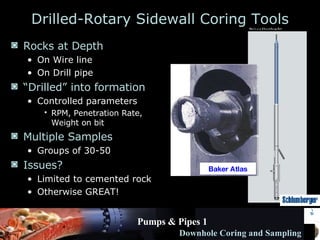

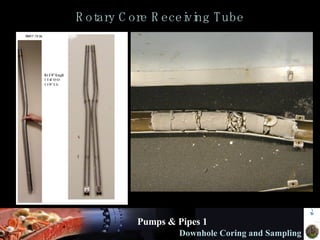

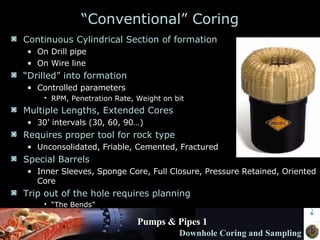

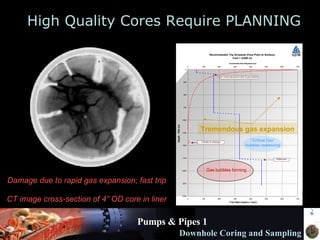

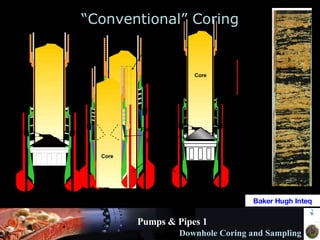

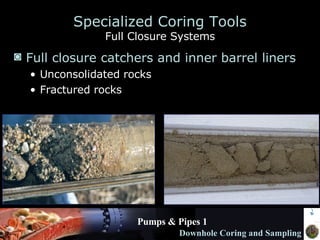

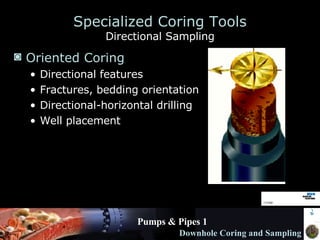

The document discusses downhole coring and sampling challenges and technologies. It describes increasing pressures and temperatures in new wells that push technological limits. It also discusses issues like fluid contamination, heterogeneous rock formations, and fractured or unconsolidated rocks. The document emphasizes that proper core processing is important for reliable lab measurements. It then outlines various downhole coring and sampling objectives, tools, and methods like conventional coring, specialized tools, and planning needed for high quality cores.