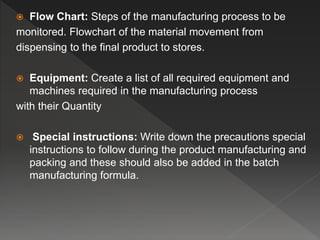

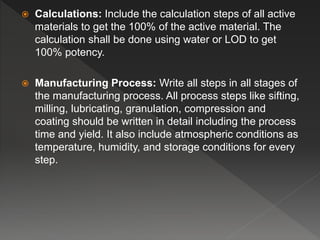

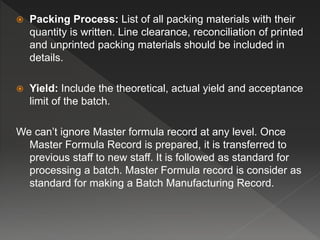

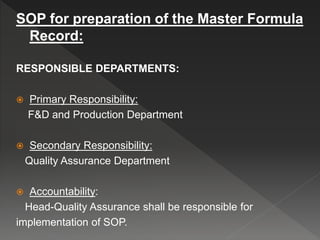

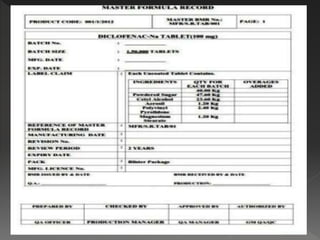

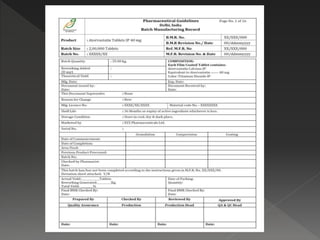

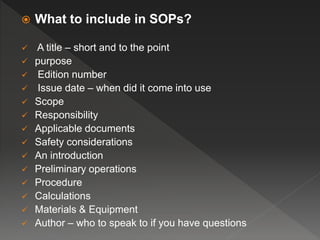

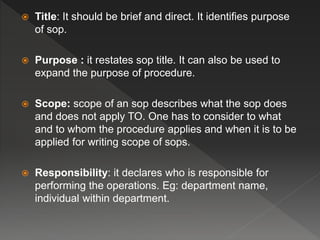

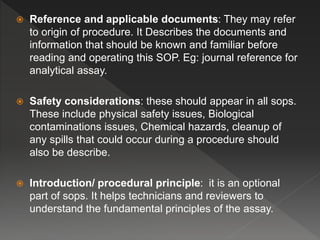

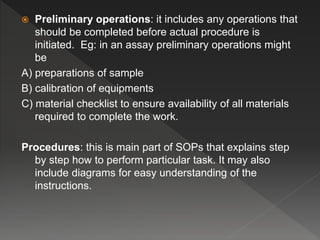

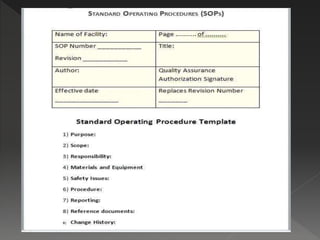

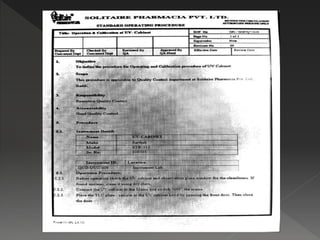

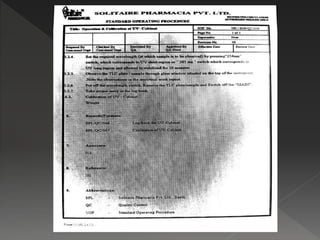

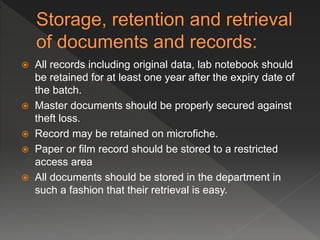

The document discusses documentation processes in organizations. It explains that documentation involves systematically recording people, events, and documents to create organizational records. Documentation provides information on how to complete tasks as well as evidence that tasks were done correctly. Master formula records (MFRs) are important documentation that contain all information about a pharmaceutical product's manufacturing process. MFRs are prepared by research teams and used as a reference for batch manufacturing records. The document outlines the key components that should be included in MFRs and batch manufacturing records to ensure consistency in manufacturing batches. It also discusses standard operating procedures and importance of documentation policies in organizations.