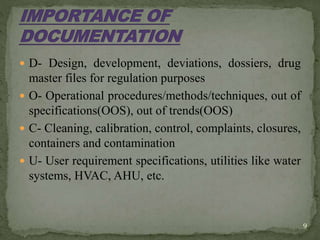

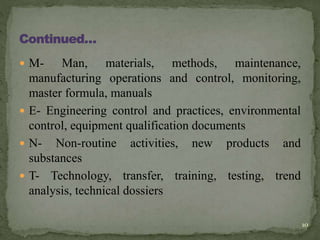

This document provides an overview of pharmaceutical documentation and quality control processes. It discusses the importance of documentation in areas like manufacturing, batch records, and quality control. The key points covered are:

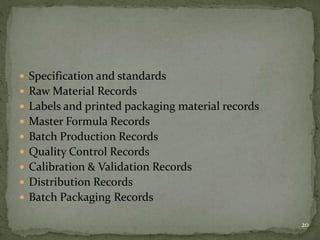

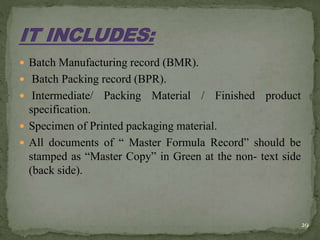

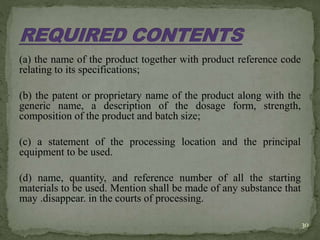

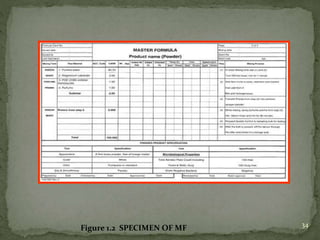

- Pharmaceutical documentation includes master formulas, batch records, quality control records, and distribution records.

- Documents must be properly controlled and approved to ensure accurate information. Controlled documents are identified, dated, approved, and retained for a specified period.

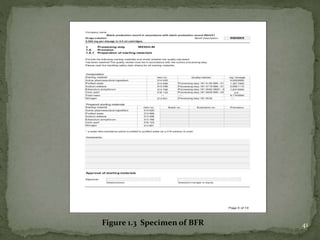

- Batch records are built from approved master formulas and provide a history of each batch production for quality purposes. They include processing details, materials used, equipment, and lab results.

- Quality control documentation helps ensure compliance and that products meet specifications. Proper documentation is