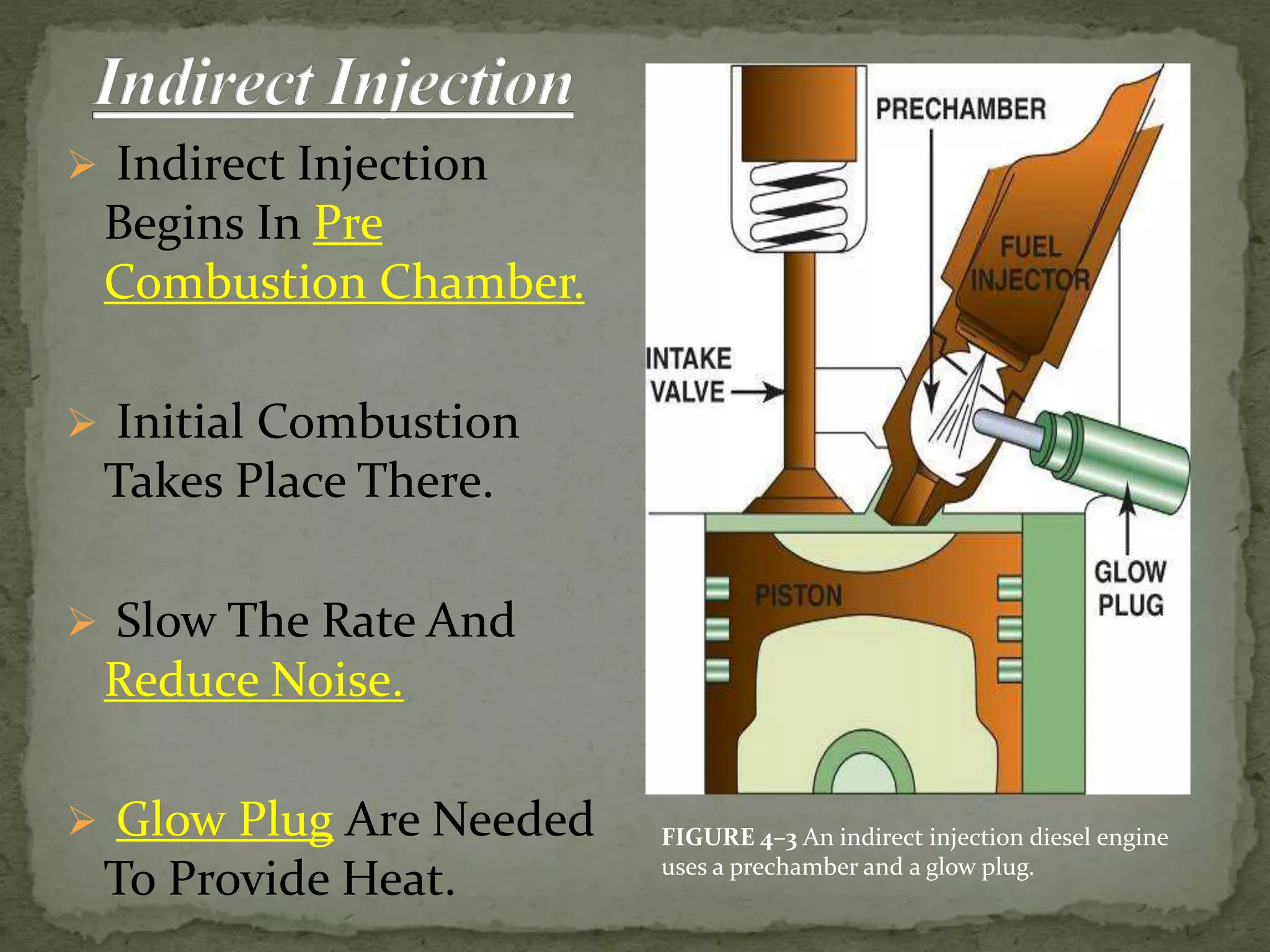

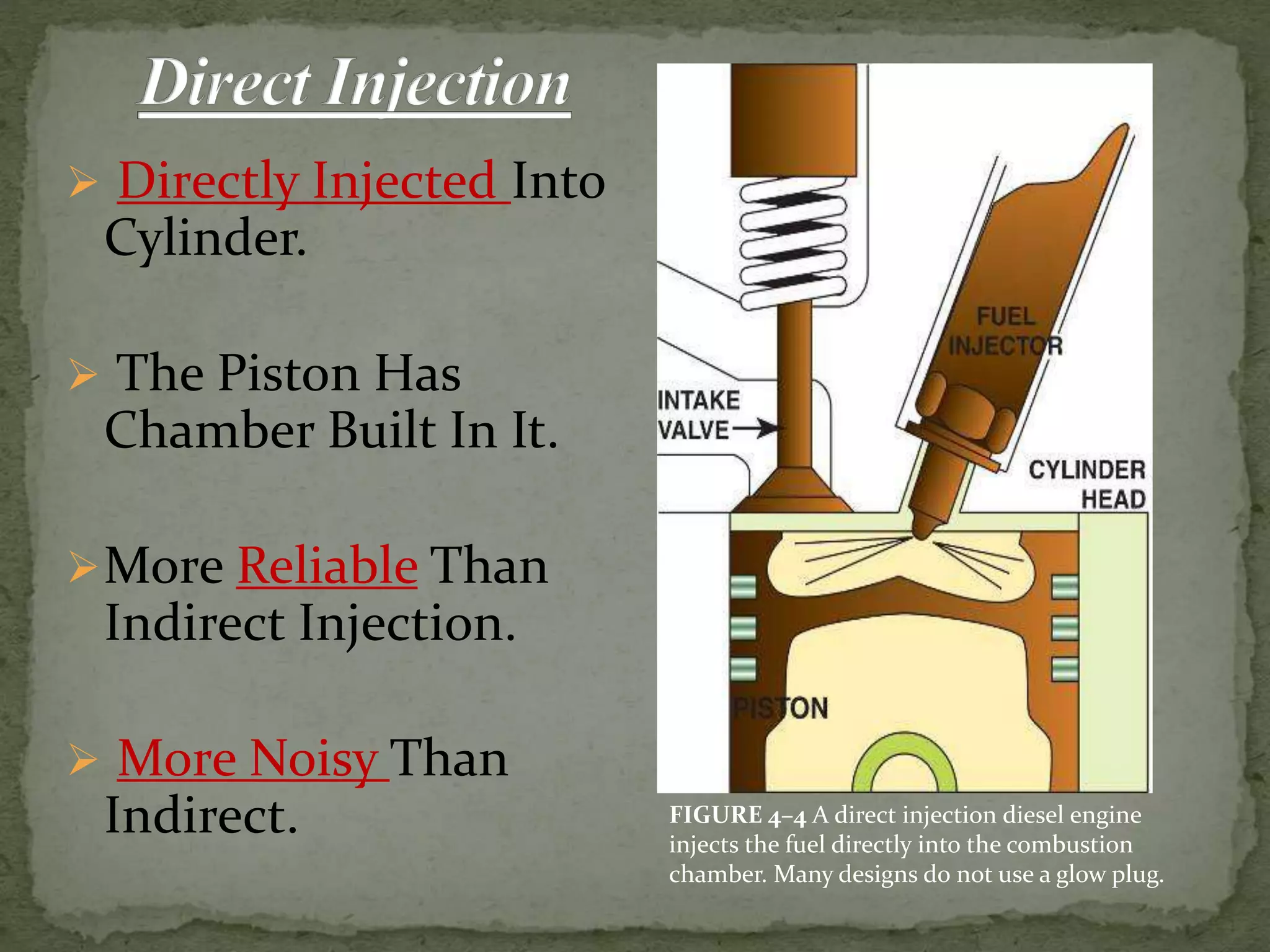

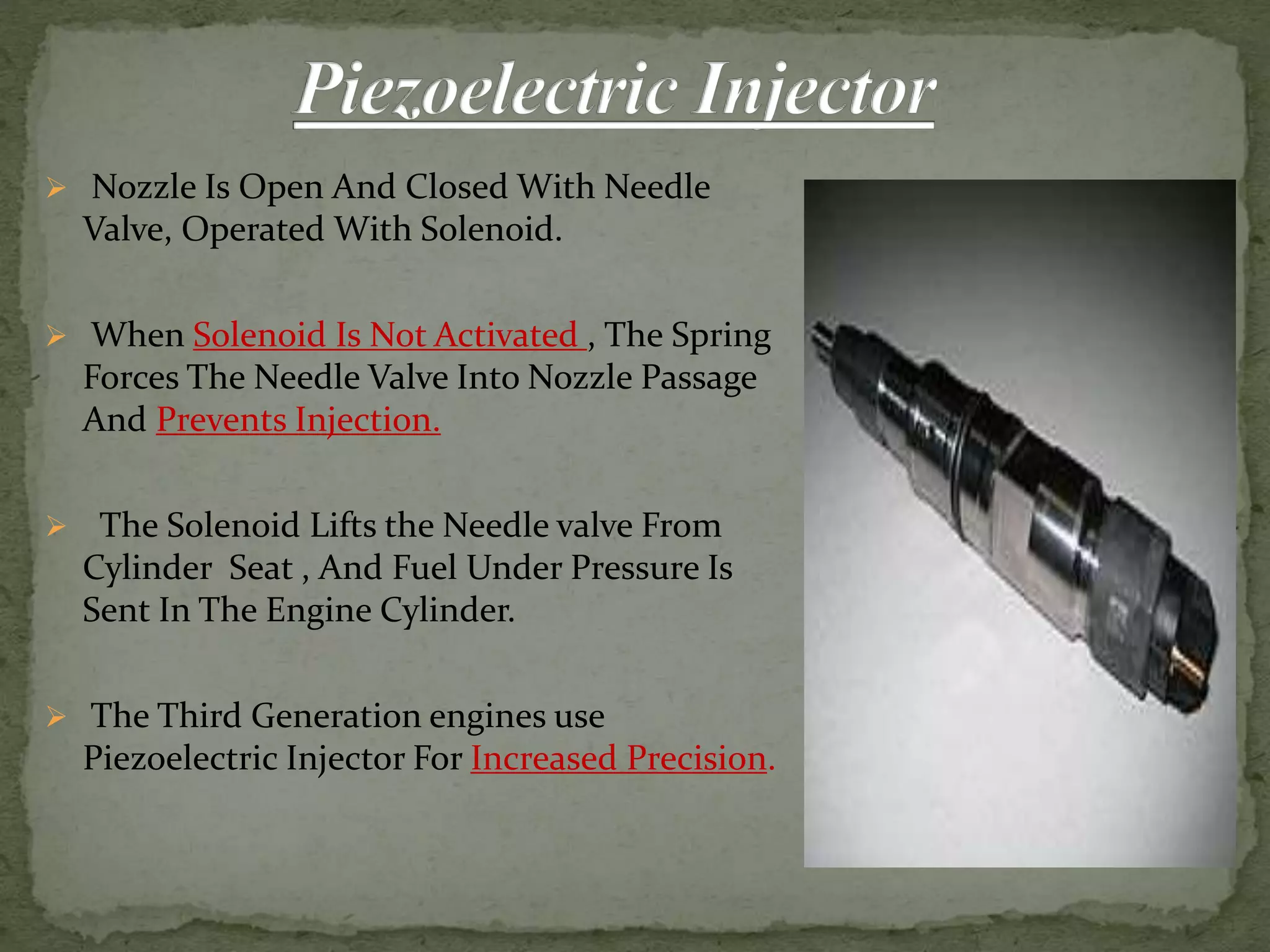

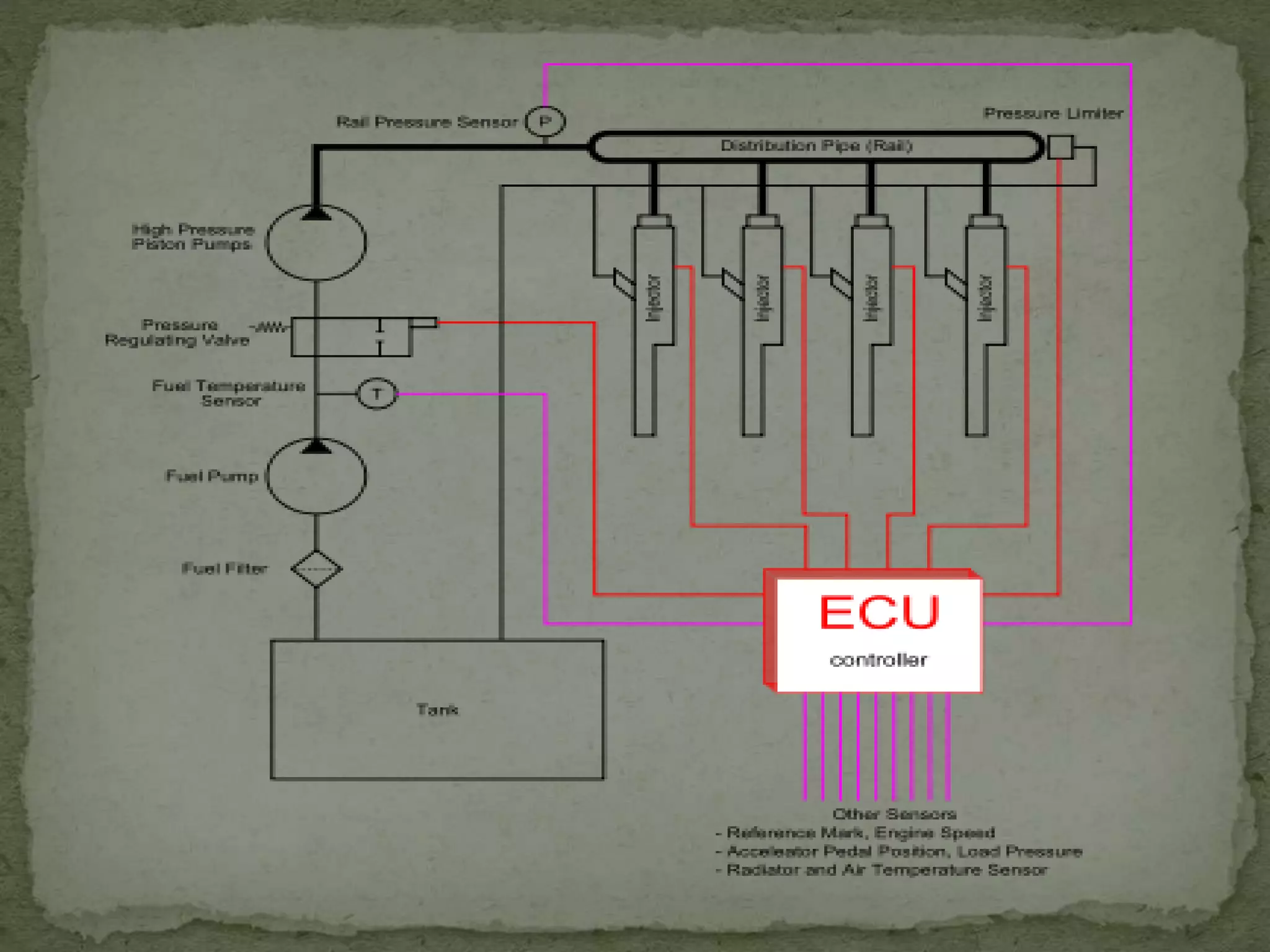

The document discusses direct diesel injection (DDI) and indirect diesel injection systems. It provides details on the operation of direct injection, including injecting fuel directly into the cylinder under pressure. Direct injection allows for better fuel atomization and combustion control compared to indirect injection. Some benefits of direct injection engines include lower emissions, higher efficiency, and reduced fuel consumption.