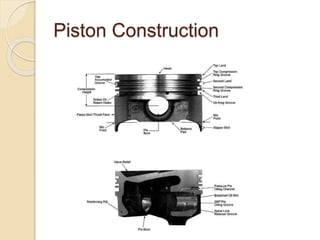

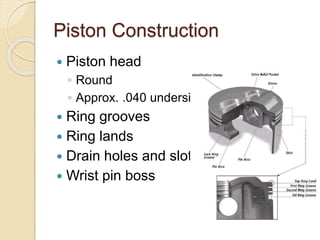

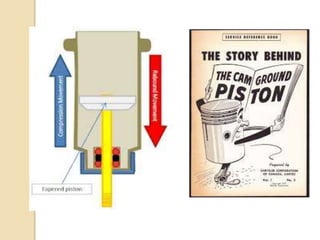

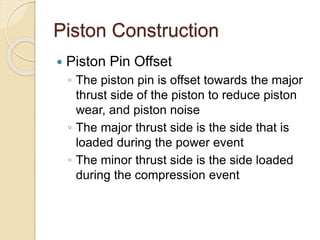

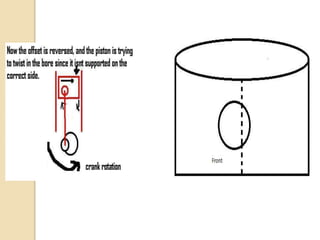

A piston is a cylindrical component that slides back and forth in the engine cylinder. It has a head at the top that is subjected to heat and pressure, and a skirt at the bottom. Piston features include ring grooves that hold piston rings to seal against the cylinder wall. Pistons must withstand pressure and heat while maintaining proper clearance in the cylinder. They are usually made of aluminum alloys and have features like struts and a cam ground shape to control expansion under operating conditions.