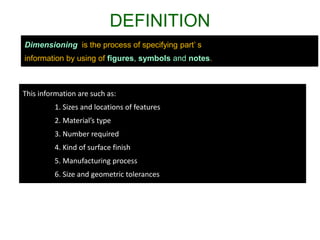

This document provides guidelines for dimensioning engineering drawings in 3 sentences:

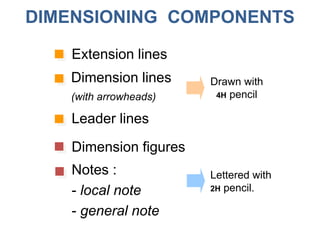

Dimensioning involves specifying an object's size, location, material, and other information using extension lines, dimension lines, leader lines, and notes to facilitate manufacturing and measurement. Key guidelines include placing dimensions outside views for clarity, using aligned or unidirectional methods for dimension figures, and noting radii, holes, chamfers, and rounded ends according to manufacturing needs. The document demonstrates best practices and common mistakes to avoid for clear and complete dimensioning of drawings.