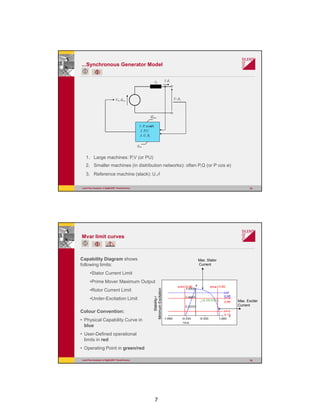

The document provides an overview of load flow analysis in DIgSILENT PowerFactory. It discusses the general procedure for load flow calculations, which involves defining node types and dispatching generators. It also describes modeling various network components like synchronous generators, loads, transformers, and transmission lines. Additionally, it covers options for load flow calculations and accessing the results. Reactive power and voltage control methods are examined as well, including transformer tap changing and station controllers.

![19

Load Flow Analysis in DIgSILENT PowerFactory 37

Voltage Profile

5.004.003.002.001.000.0-1.00 [km]

789

2924

2445

4218

459

245

Infeed

0.984

0.980

0.976

0.972

0.968

0.964

0.960

[p.u.]

Voltage, Magnitude

LowerLimity=0.962p.u.

4.037 km

1.000 km

0.975 p.u.

DIgSILENT

Feeder Voltage Profile Voltage Profile Date: 8/23/2000

Annex: Distr.2 /1

DIgSILENT

Voltage profile, overloading and limits in one diagram

Load Flow Analysis in DIgSILENT PowerFactory 38

Load Scaling

• Load Scaling:

- Edit or create feeder definition:

- Options:

a ) no scaling

b) scaling to measured reactive power

c) scaling to measured active power

d) scaling to measured current

• Loads that are to be scaled in order to match the measured value must be

marked as such

Option in the load „Adjusted by Load Scaling”

• Load scaling must be enabled in the loadflow command

Option: „Feeder Load Scaling”](https://image.slidesharecdn.com/03loadflowanalysis-170517220511/85/DigSILENT-PF-03-load-flow-analysis-19-320.jpg)