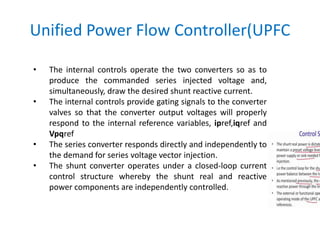

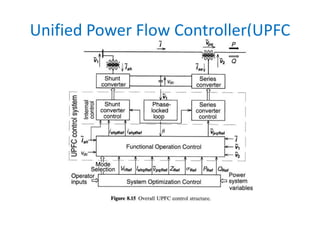

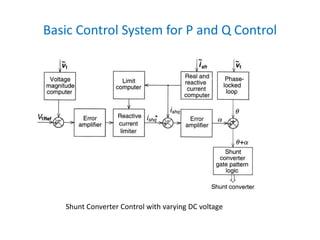

The UPFC uses vector control to independently control the real and reactive power flow in transmission lines. It consists of two voltage-sourced converters connected back-to-back through a DC link. The shunt converter can generate or absorb reactive power while the series converter injects an AC voltage in series with the transmission line. This allows various control modes including reactive power compensation, voltage regulation, phase shifting, and automatic real and reactive power flow control to manage power transmission.