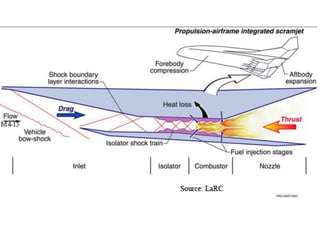

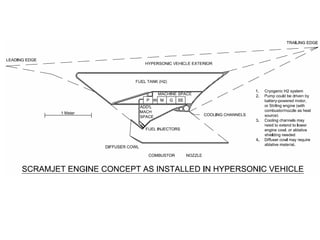

This document summarizes the design of a scramjet engine for Mach 5 flight. It outlines the benefits and challenges of scramjet technology, including that it is air-breathing and has no moving parts but requires special heat-resistant materials. The document then details the design process, which used a quasi-1D flow analysis method to model the inlet, combustor, and nozzle for Mach 5 flight at 15 km altitude. The results showed thrust of 405 kN, specific impulse of 174 seconds, and efficiencies around 0.8-0.9. However, the engine would only be viable installed on a large vehicle and requires improved combustion modeling for higher supersonic speeds.