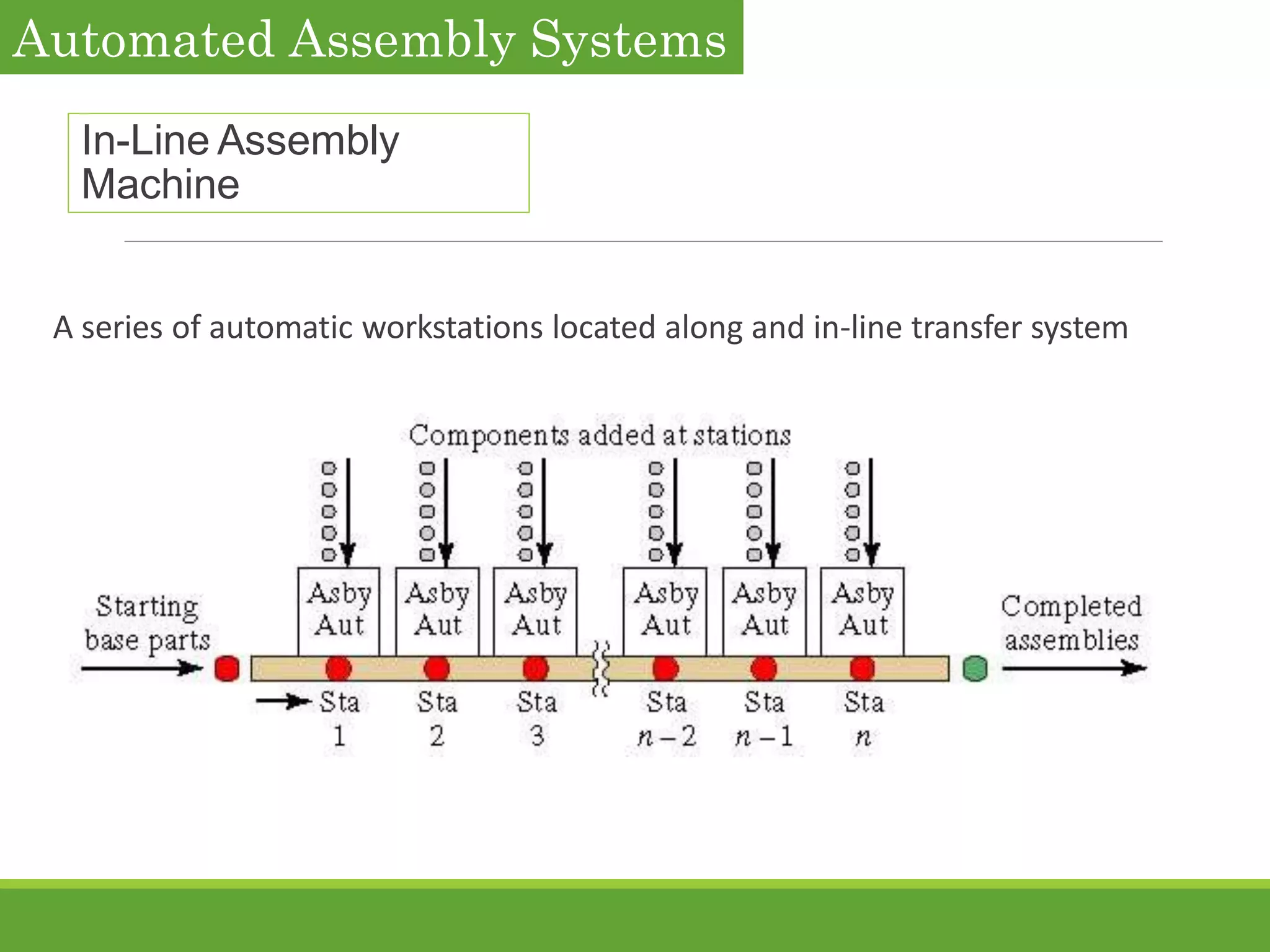

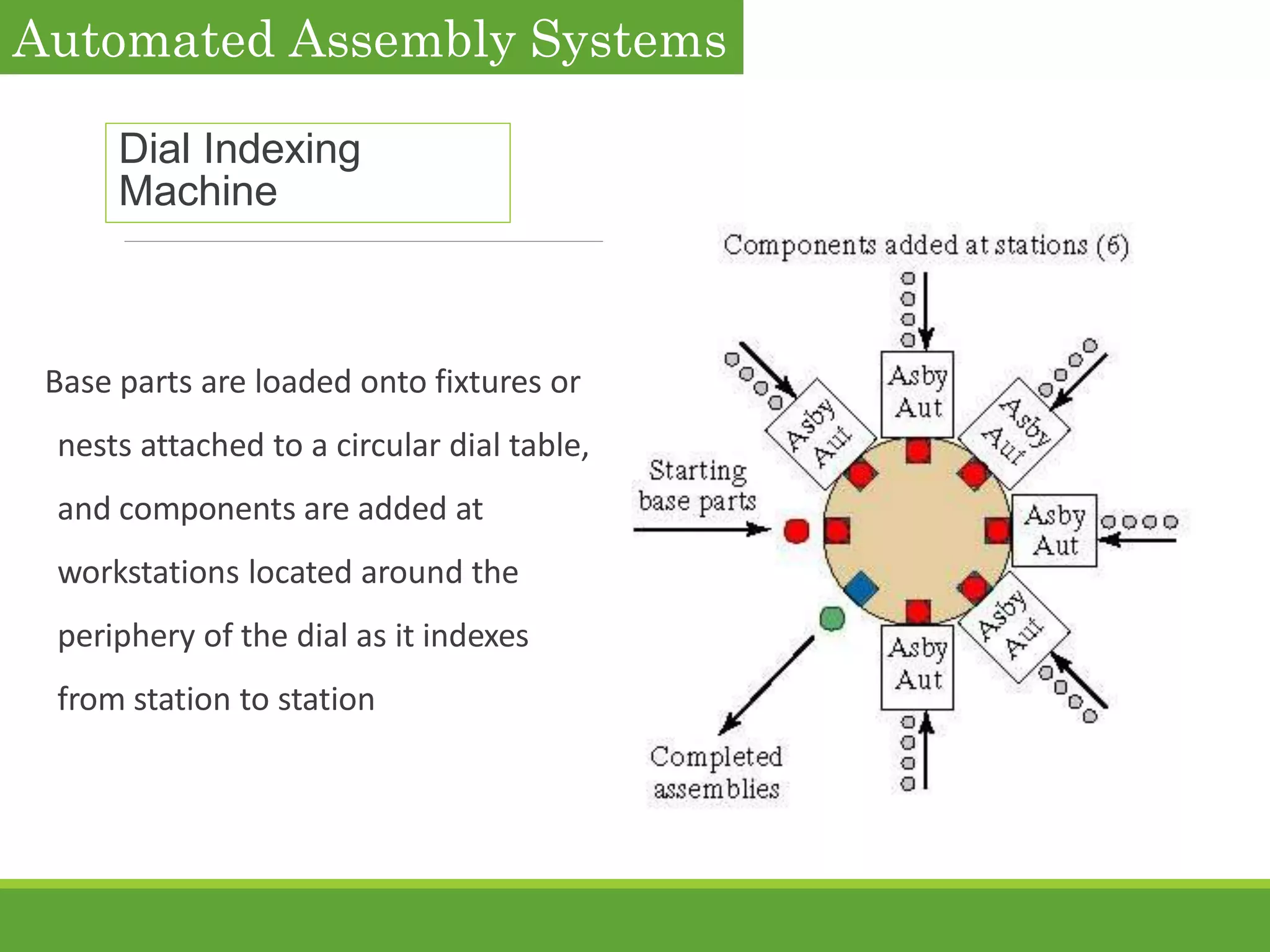

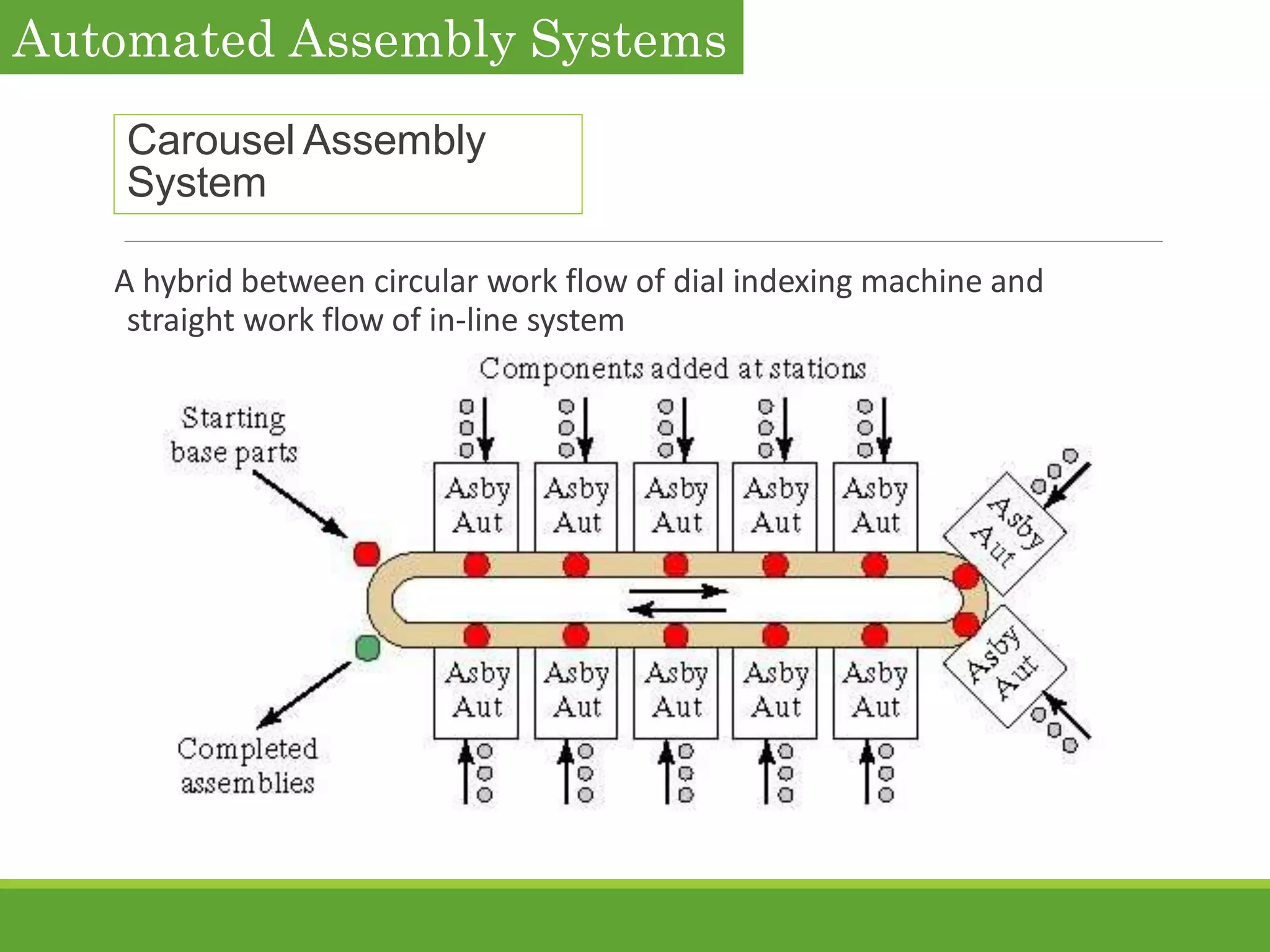

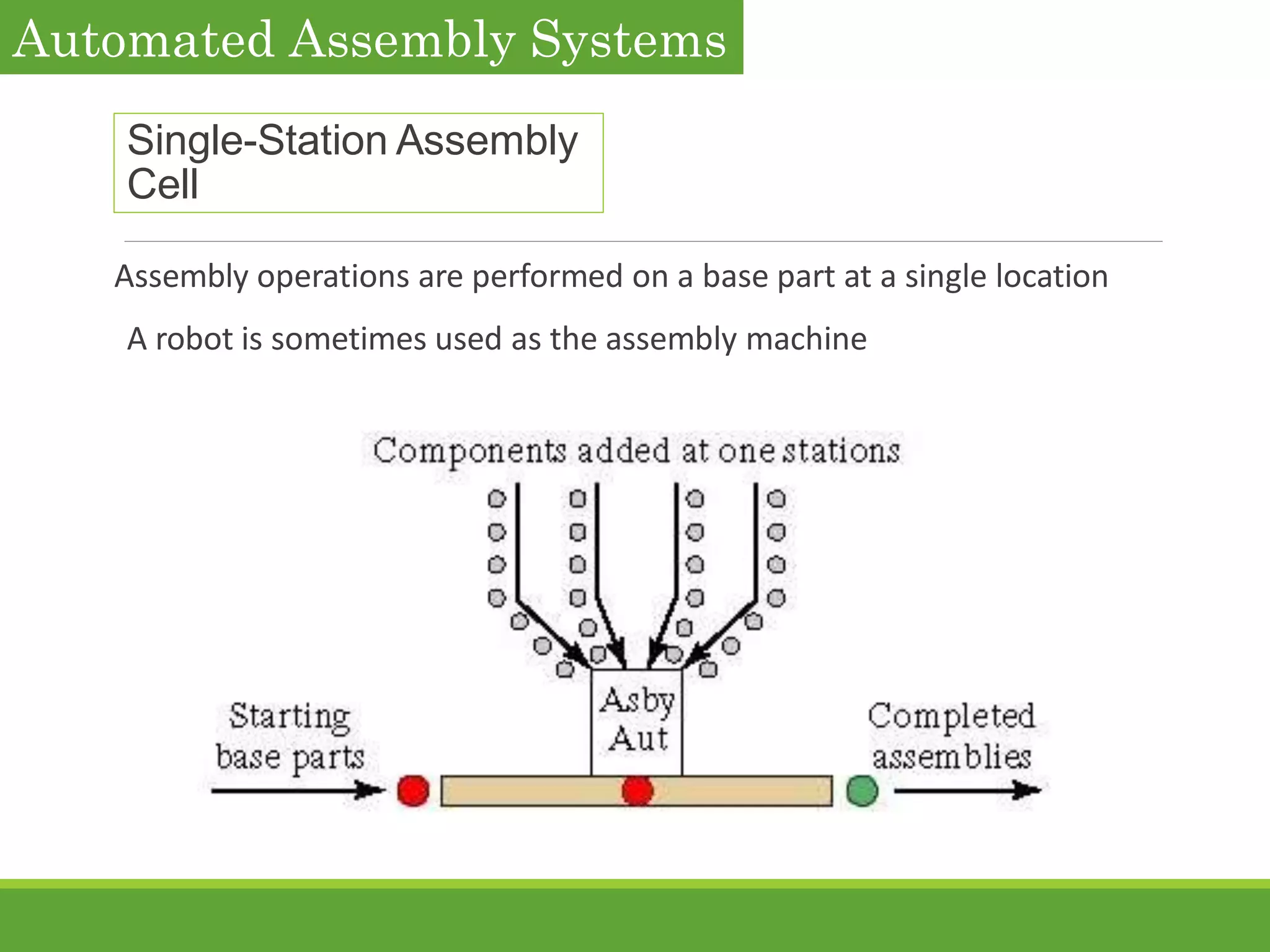

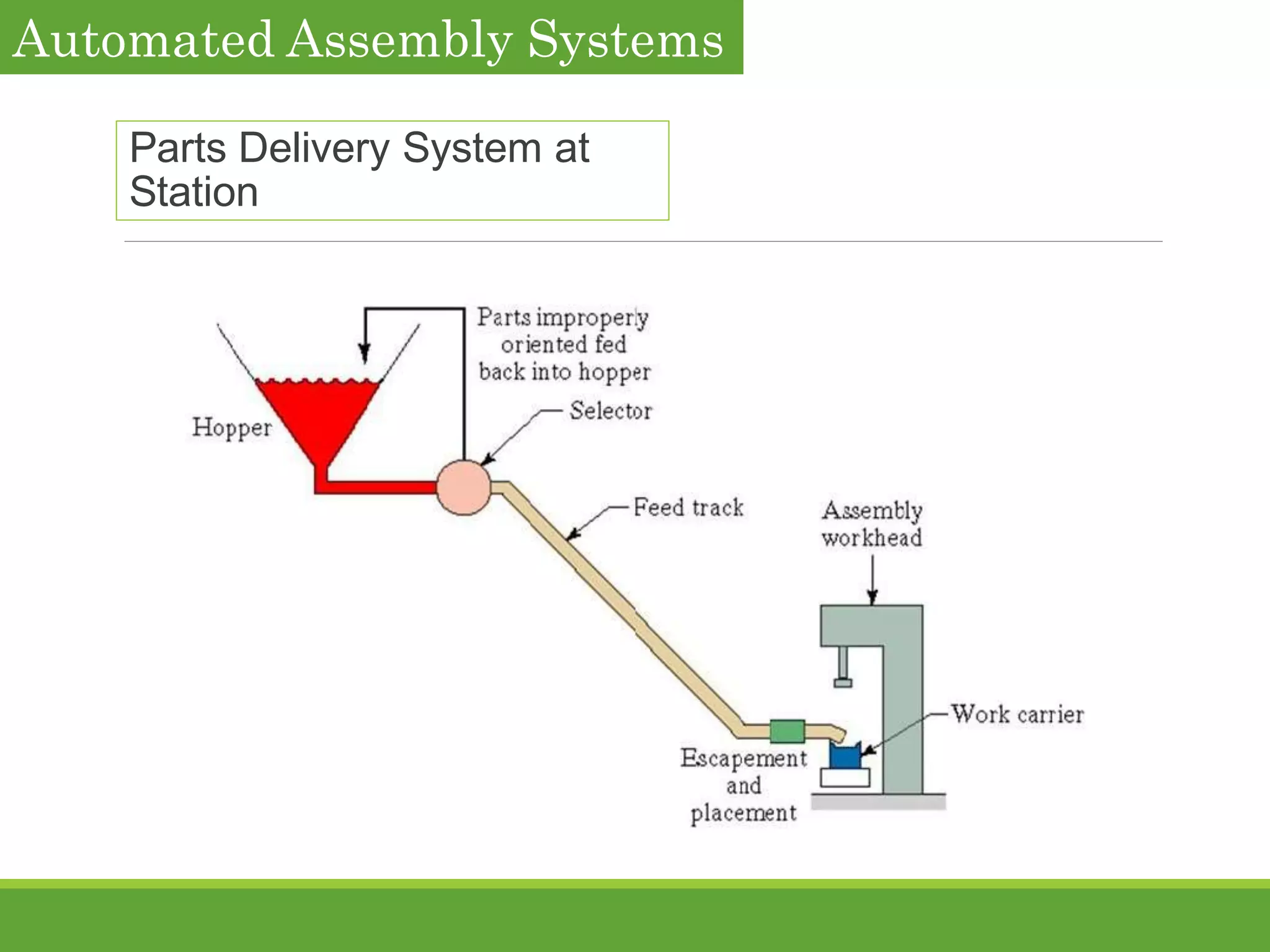

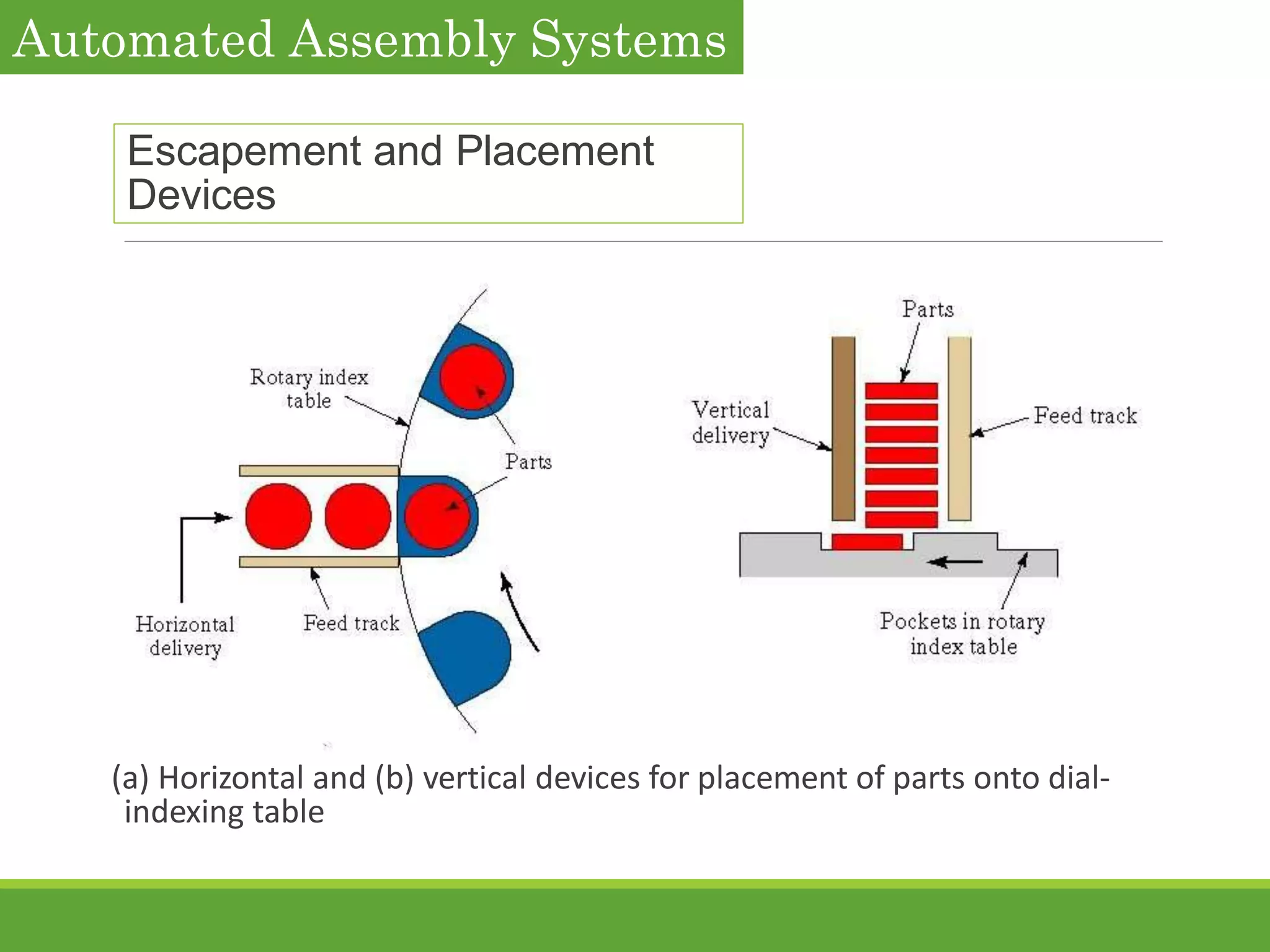

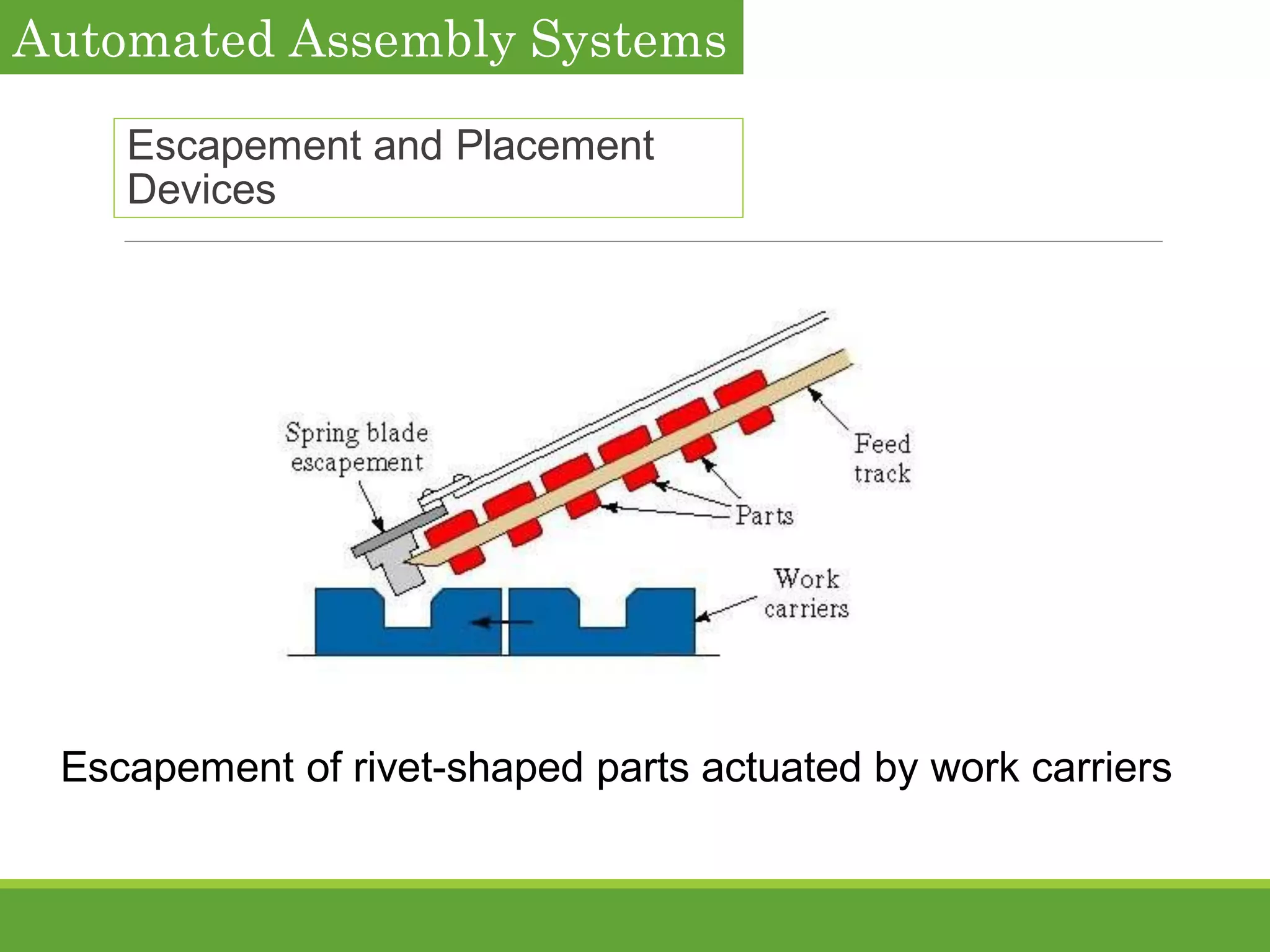

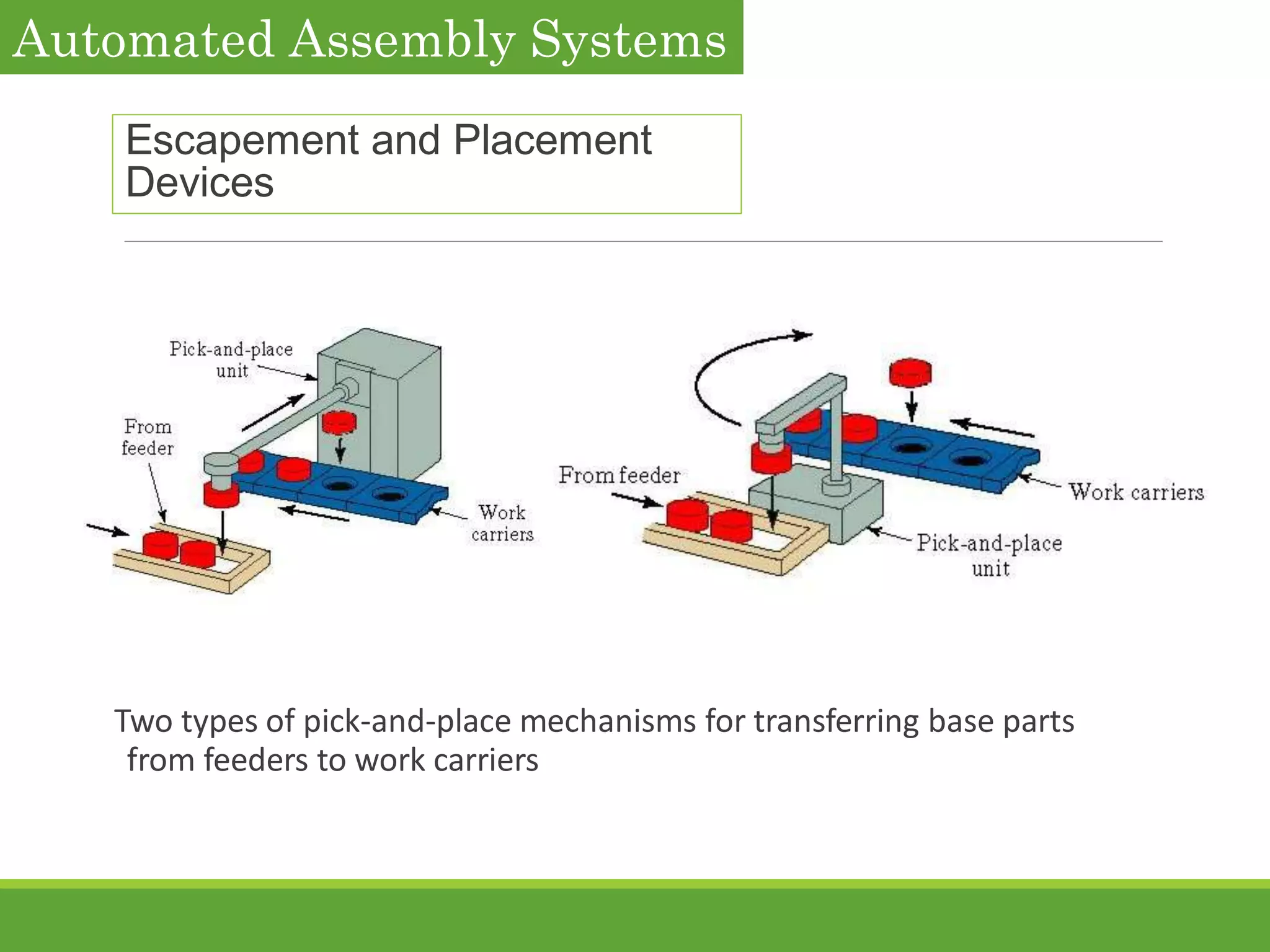

Automated assembly systems can be used to perform repetitive assembly tasks at high rates. There are several types of automated assembly systems including in-line assembly machines, dial indexing machines, carousels, and single-station cells. The key components are parts delivery systems that orient and position components correctly and assembly workheads that attach components together. Automated assembly is well-suited for high-volume production of stable designs with a limited number of parts but the performance depends on component quality and station reliability.