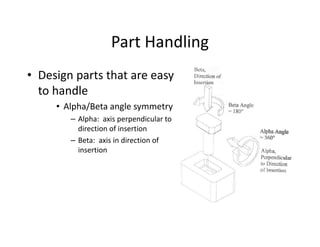

Design for Assembly (DFA) aims to optimize product assembly through minimizing part count, analyzing assembly steps, and designing parts for easy handling and insertion. The DFA process examines assembly steps to identify non-value-added tasks, part relevance to reduce theoretical part count, and part design features to enable simple, mistake-proof assembly like symmetry and self-alignment. The goal is to design products that can be assembled quickly and at lowest cost.