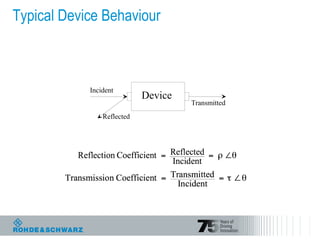

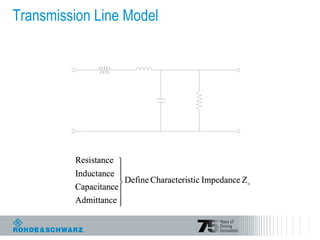

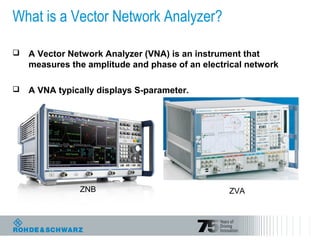

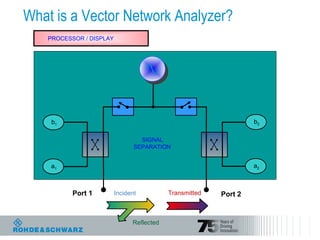

This document discusses using a vector network analyzer (VNA) for signal integrity testing. It begins with an overview of RF connectors and their impact on measurement accuracy. It then describes how a VNA works, measuring both amplitude and phase to determine S-parameters. Key aspects covered include calibration to define a reference plane, measuring transmission and reflection parameters, and converting frequency domain data to the time domain. Applications discussed include time domain reflectometry for fault detection and measuring rise times.

![28

Why use Vector Network Analysis?

Very low level signals can be measured more accurately with

narrow bandwidths

Can measure very fast Rise Times

The 4-port, single-ended S parameters have become a de-facto

standard for describing the electrical properties of any 4-port

interconnect.

ı For example, IEEE P802.3ap Task Force uses measured S-parameters as test cases

[9] for proposed solutions to the problem of 10 Gbit/s Ethernet over backplanes.

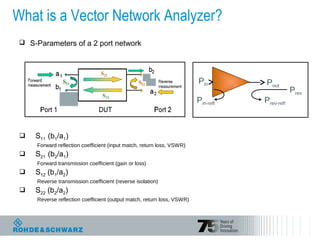

What are the numbers in S..

o the first index being the going out port

o the second index is the coming in port.

o Example: Gain or Loss of Device is S21](https://image.slidesharecdn.com/17ad722e-20ef-4c8b-ab9a-766a8d562210-150207005816-conversion-gate02/85/Design-Con-VNA-28-320.jpg)

![Reslution and Resolution Enhancement Factor

0,00E+00

5,00E-02

1,00E-01

1,50E-01

2,00E-01

2,50E-01

3,00E-01

3,50E-01

-2,00E-09 0,00E+00 2,00E-09 4,00E-09 6,00E-09 8,00E-09 1,00E-08 1,20E-08

time [ns]

ReflectionFactor[U]

ZVA: 1 GHz - 20 GHz ZNB: 1 GHz - 8 GHz REF: 2.5

ZVA: Start: 10 MHz - 20 GHz

ZNB: Start 10 MHz - 8 GHz, REF: 2.5

fstep: 10 MHz](https://image.slidesharecdn.com/17ad722e-20ef-4c8b-ab9a-766a8d562210-150207005816-conversion-gate02/85/Design-Con-VNA-55-320.jpg)