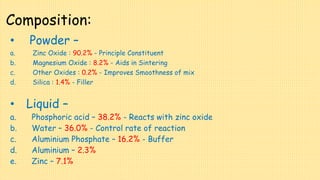

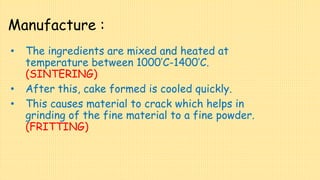

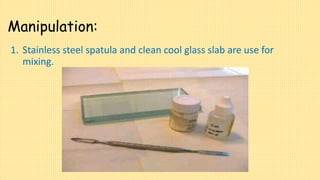

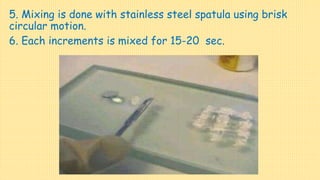

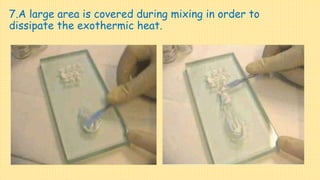

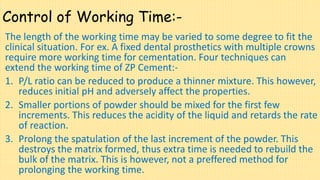

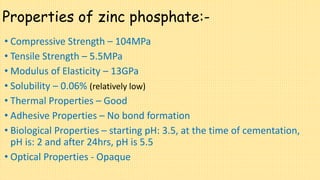

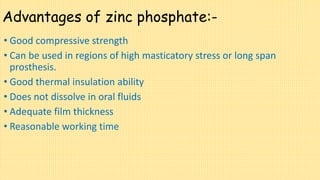

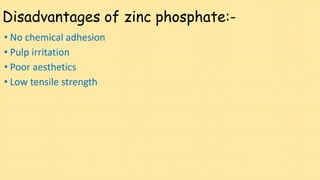

Zinc phosphate cement is an older luting cement that exists in two types based on grain size. It consists of zinc oxide powder and an acidic liquid containing phosphoric acid. The powder and liquid undergo an exothermic chemical reaction where the acid attacks the zinc oxide particles. This forms a zinc-aluminophosphate gel matrix. Zinc phosphate cement has good compressive strength and insulation properties but low tensile strength. It is used for luting restorations and bases due to its strength but can irritate pulp and lacks aesthetic qualities. The working time can be extended through controlling the powder-liquid ratio, mixing temperature or technique.