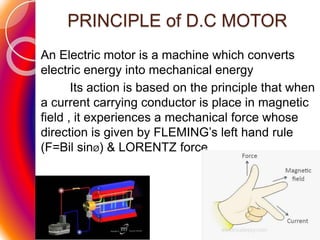

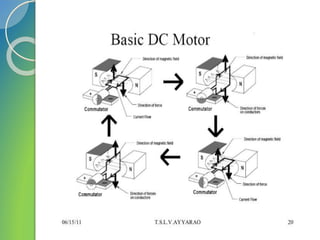

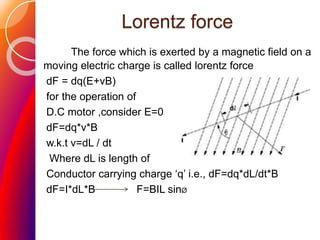

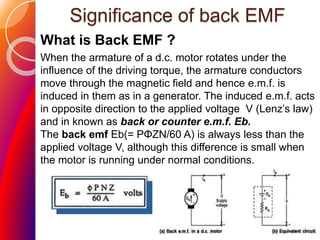

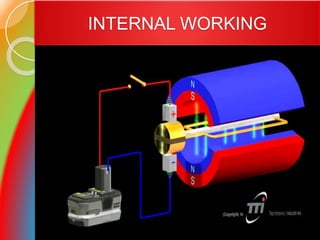

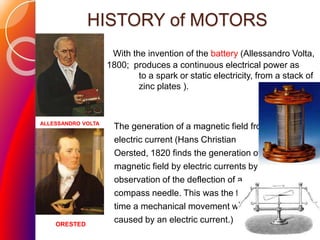

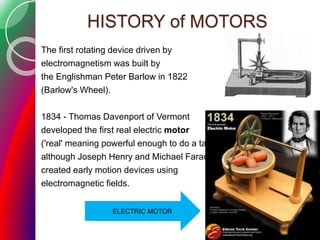

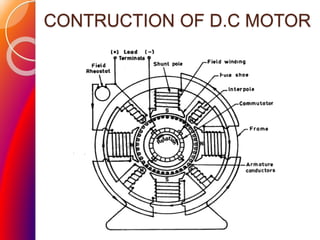

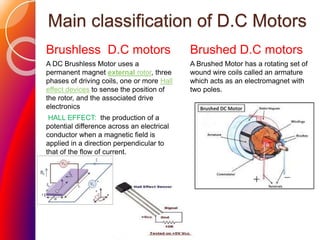

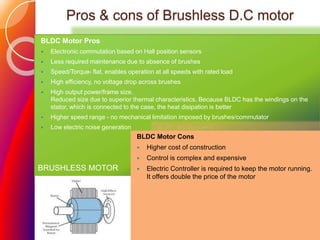

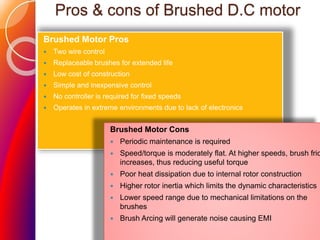

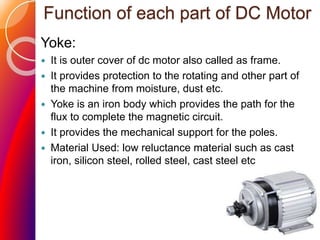

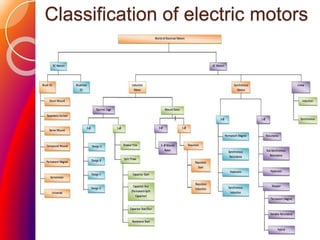

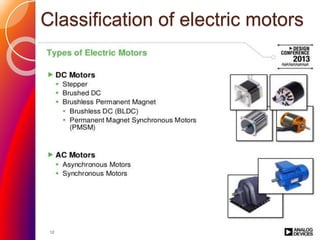

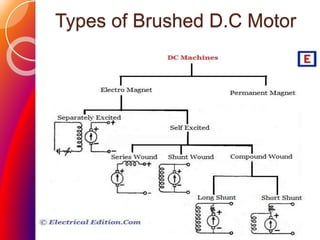

The document discusses the principles and components of DC motors. It begins by explaining that a DC motor converts electrical energy to mechanical energy using electromagnetic forces generated when a current-carrying conductor is placed in a magnetic field. It then describes the Lorentz force equation and how it relates to the operation of DC motors. The document goes on to define the back EMF produced in a DC motor and its significance. It provides histories of early electric motors and inventors. It also classifies DC motors, describes the functions of their main components like the yoke and field coils, and gives examples of applications for different DC motor types.