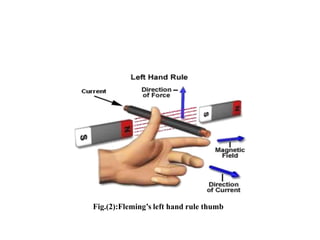

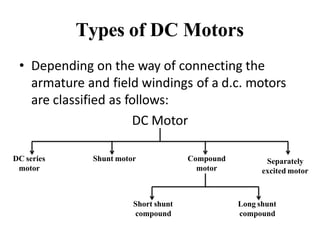

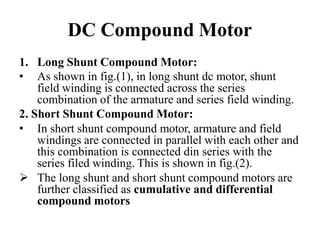

DC motors operate by generating rotational motion from electrical power. They have three main parts: the armature, field coils, and commutator. When current passes through the field coils, a magnetic field is produced. The armature, situated in this field, has its own coils that experience a force when current passes through. This causes the armature to rotate. The commutator and brushes allow the current in the armature coils to be reversed to maintain rotation. DC motors come in different types depending on how the field and armature coils are connected, including shunt, series, and compound motors, each with their own speed-torque characteristics.