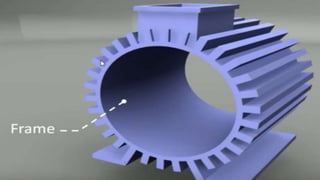

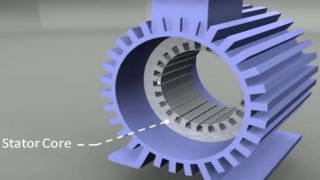

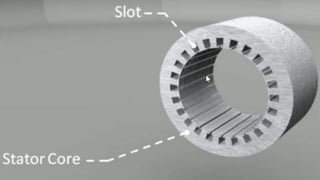

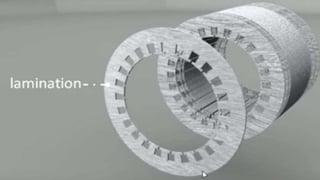

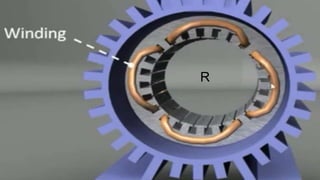

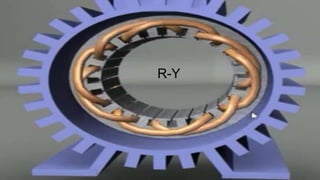

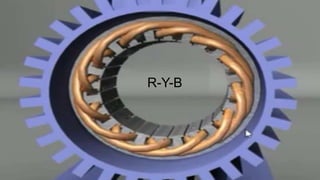

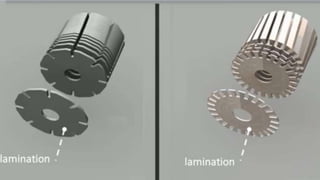

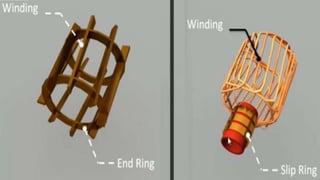

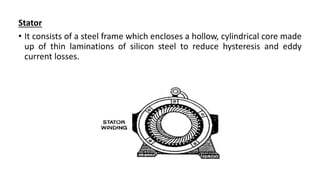

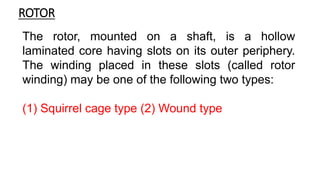

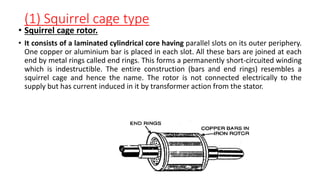

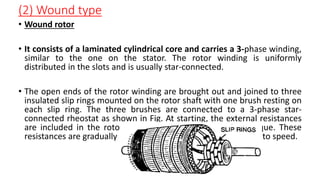

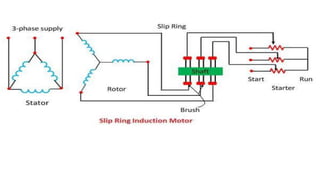

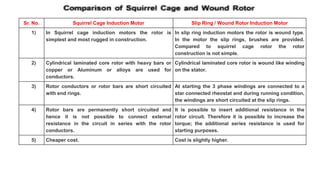

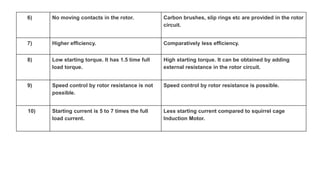

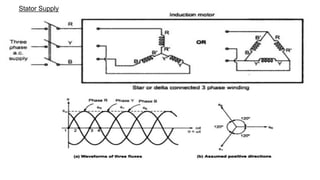

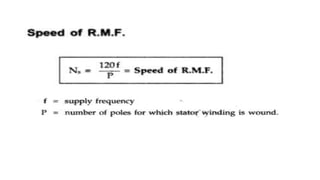

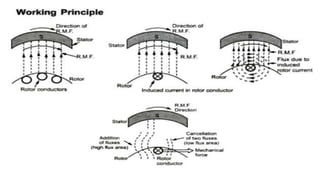

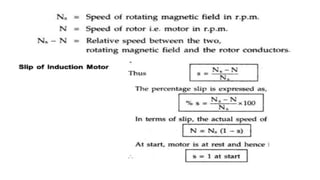

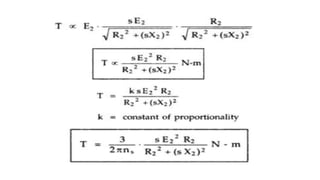

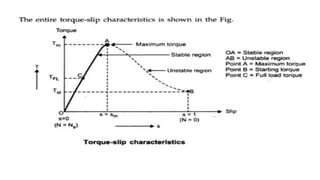

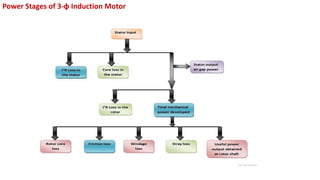

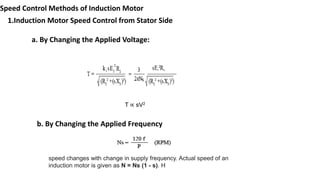

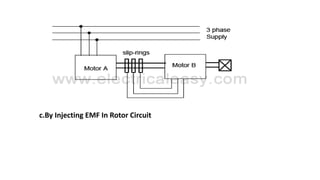

The document discusses three phase induction motors. It describes the basic construction of three phase induction motors including the stator and rotor. The rotor can be either a squirrel cage type or wound type. The squirrel cage rotor is the most common due to its simple and rugged construction. The document also covers the rotating magnetic field produced by three phase currents on the stator, torque-slip characteristics, and various speed control techniques such as changing the supply voltage or frequency.