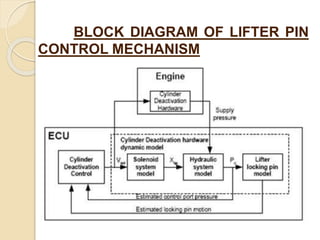

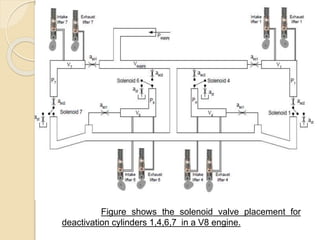

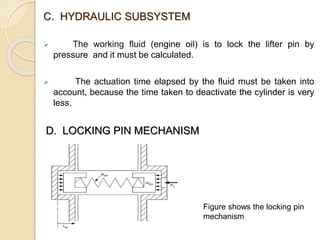

This document discusses cylinder deactivation systems, which deactivate cylinders to improve fuel efficiency when full engine power isn't needed. It introduces the topic and explains that cylinder deactivation was developed to reduce fuel consumption in cities where less power is required. It then describes three main methods: lifter pin control mechanism, variable profile camshaft, and active valve train technology. For lifter pin control mechanism, it provides details on how solenoid valves and locking pins deactivate cylinders to decouple the camshaft. Cylinder deactivation systems can increase fuel efficiency and decrease emissions, but also result in increased vehicle weight and manufacturing costs.