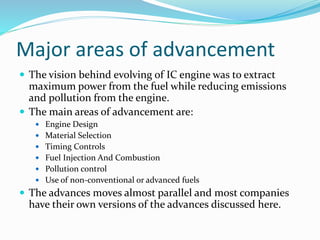

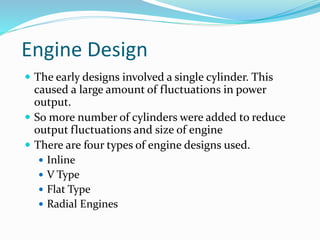

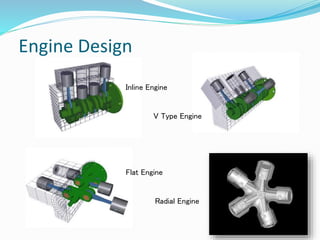

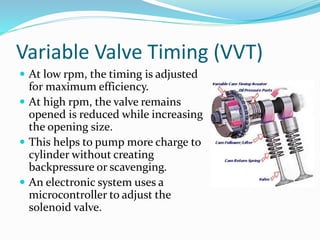

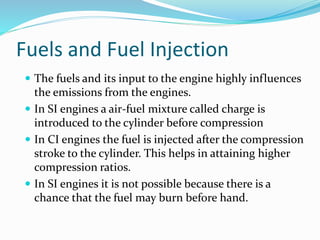

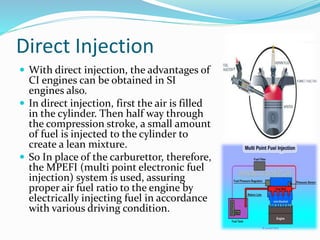

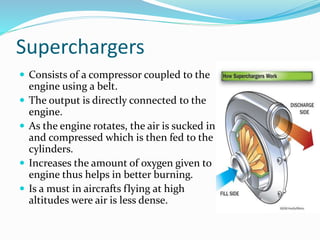

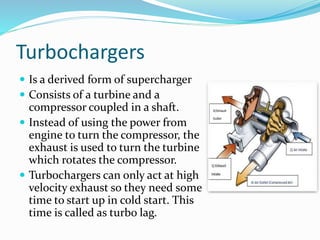

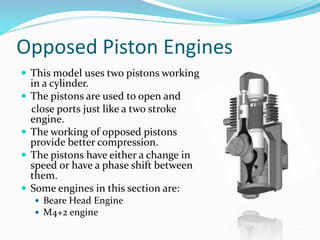

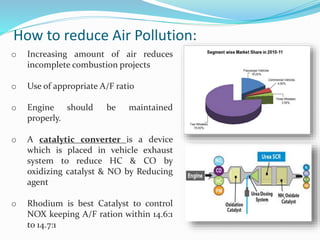

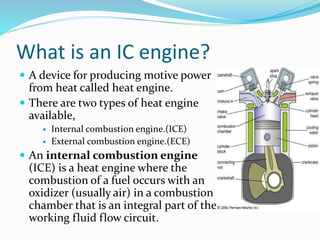

The document discusses the advancement of internal combustion engines. It covers topics like the classification of IC engines based on combustion and strokes. Major areas of advancement discussed include engine design, material selection, timing controls, fuels and fuel injection systems, and pollution control. Some specific technologies covered are variable valve timing, direct injection, superchargers, turbochargers, six-stroke engines, and methods to reduce air pollution from engines like catalytic converters. The goals of engine advancement are listed as higher power, better fuel efficiency, lower emissions and weight.

![Classification of IC engines

Two main classifications:

Based on combustion

Spark Ignition [SI engines] (Eg: Petrol Engine)

Compression Ignition [CI engines] (Eg: Diesel

Engine)

Based on Number of strokes

Two stroke

Four Stroke

Six Stroke](https://image.slidesharecdn.com/advancementoficengine-200717170019/85/Advancement-of-IC-engine-4-320.jpg)