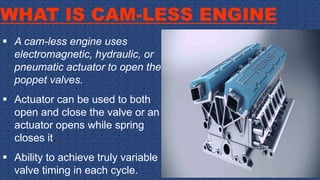

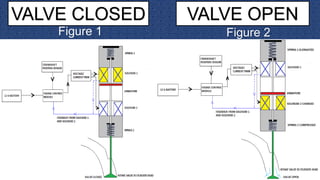

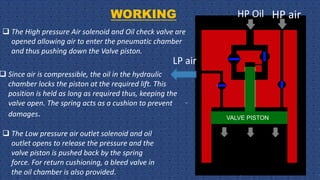

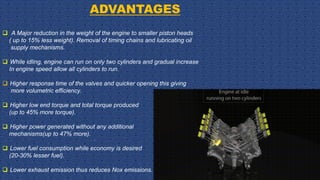

The document discusses the development of cam-less engines, which utilize piezoelectric controlled hydraulic actuators to replace traditional camshafts, allowing for improved engine performance and fuel efficiency. It describes the working principles of conventional engines, advantages of cam-less systems such as reduced weight and lower fuel consumption, and the potential for truly variable valve timing. However, it also notes challenges such as the high cost of technology and the current state of development requiring further research.