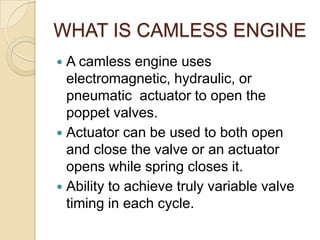

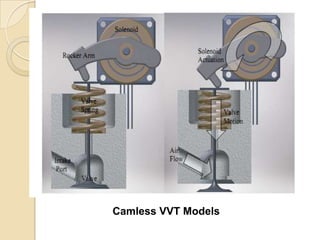

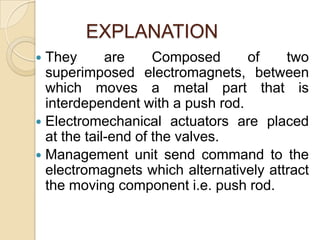

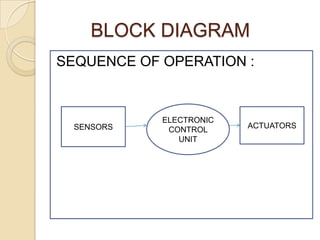

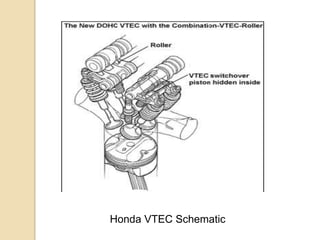

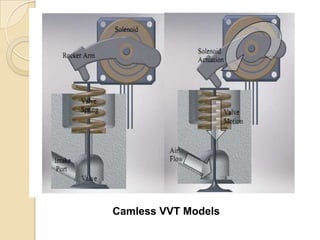

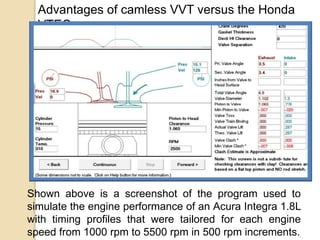

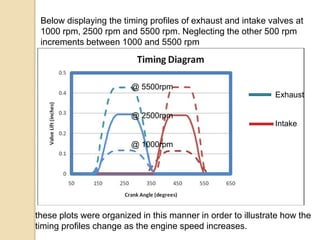

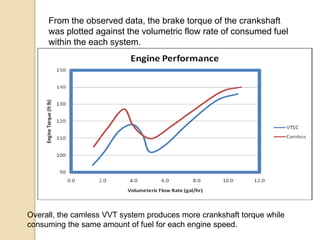

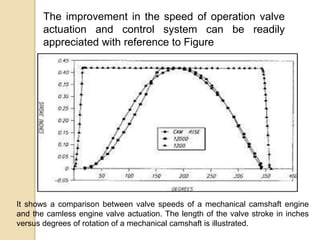

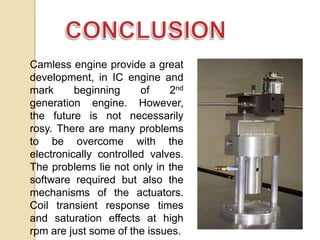

The document discusses the development and benefits of a camless engine. A camless engine uses electromagnetic, hydraulic, or pneumatic actuators instead of a camshaft to open the engine valves. This allows for truly variable valve timing in each engine cycle. The document describes two main types of camless systems - electromechanical and electrohydraulic. An electromechanical system uses solenoid actuators controlled by a microcontroller to open the valves. An electrohydraulic system uses electrically controlled hydraulic valves and actuators. Simulation results show the camless engine improves fuel economy by up to 6.5% compared to existing cam-based systems, while producing more torque.