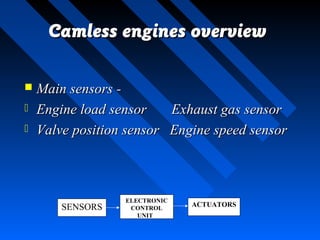

Camless engines eliminate mechanical linkages between the crankshaft and valves. Sensors monitor engine parameters and send signals to an electronic control unit (ECU). The ECU then controls solenoid valves and hydraulic actuators to open and close the valves according to requirements, allowing infinite variability of valve timing, lift, and duration. This makes engines more efficient and responsive compared to conventional camshaft-controlled engines.