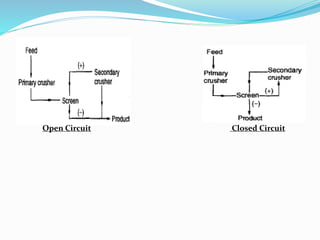

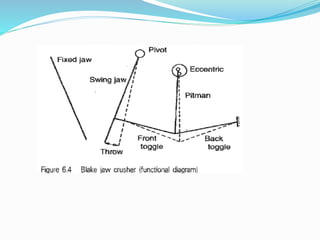

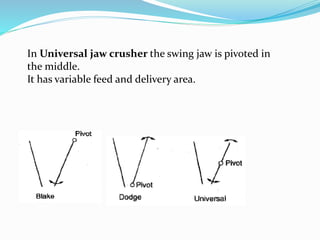

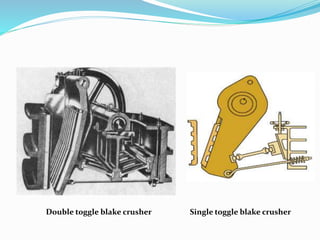

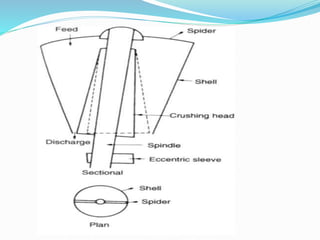

Crushing is the first mechanical stage in the comminution process for extracting and refining ore. It typically occurs in two or three stages, with primary crushing reducing ore sizes from 1.5m to 10-20cm using heavy-duty machines. Crushing can be done via open or closed circuits. Primary crushers, like jaw and gyratory crushers, are heavy-duty machines that reduce run of mine ore sizes for transport and feeding to secondary crushers. Jaw crushers consist of two plates that open and close to crush material, and come in blake, dodge, and universal styles that vary feed and discharge areas.