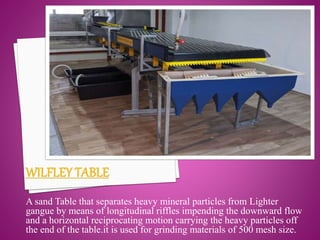

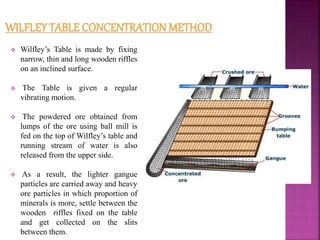

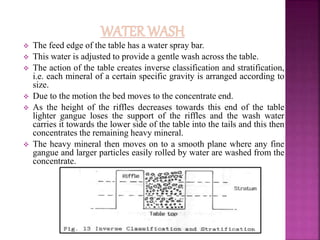

The Wilfley table is used to separate heavy mineral particles from lighter waste particles using riffles and vibration. Powdered ore is fed onto the table along with water. Heavier particles settle between the wooden riffles while lighter particles are washed away. As the table vibrates, the bed of particles moves toward the concentrate end where riffles decrease in height, allowing lighter particles to be washed off while concentrating the heavier minerals. Proper maintenance of parts like the drive box and rocker arms is needed to keep the Wilfley table functioning effectively.