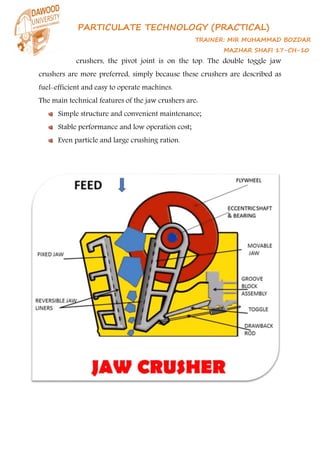

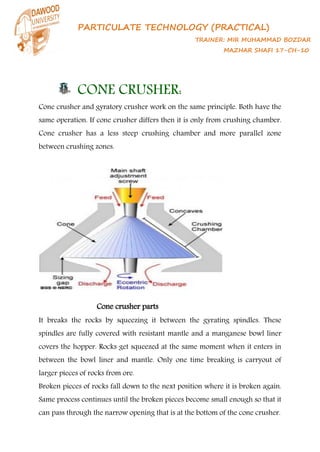

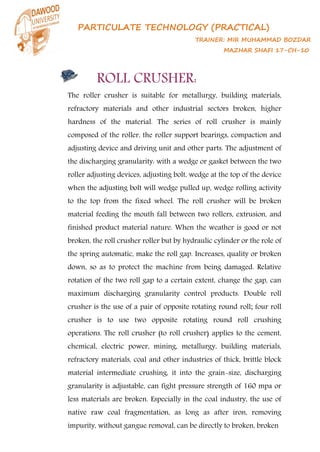

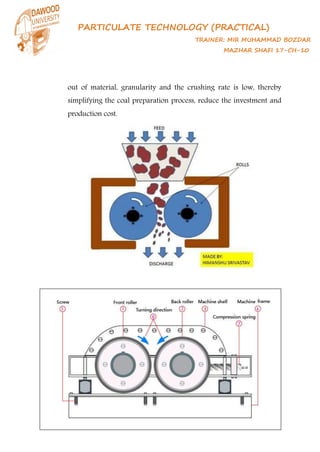

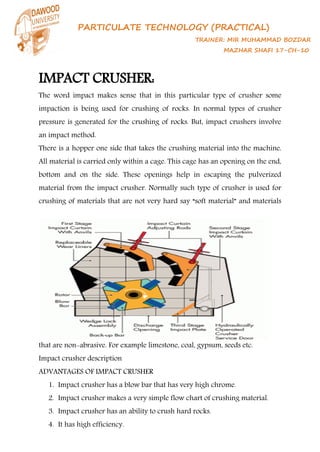

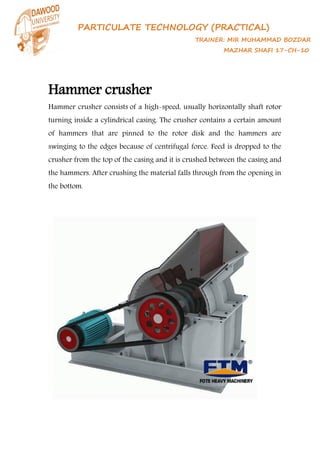

A crusher is a machine that reduces large rocks into smaller pieces by using impact, attrition, shear, or compression. There are four main types of crushers: jaw crushers, gyratory crushers, cone crushers, and roll crushers. Jaw crushers use compression force to break rocks between a fixed and moving surface, while gyratory and cone crushers use a similar principle with a gyrating motion to break rocks inside an enclosed chamber. Roll crushers use cylindrical rollers to crush material. Each crusher type has different features that make it suitable for different applications depending on the material properties.