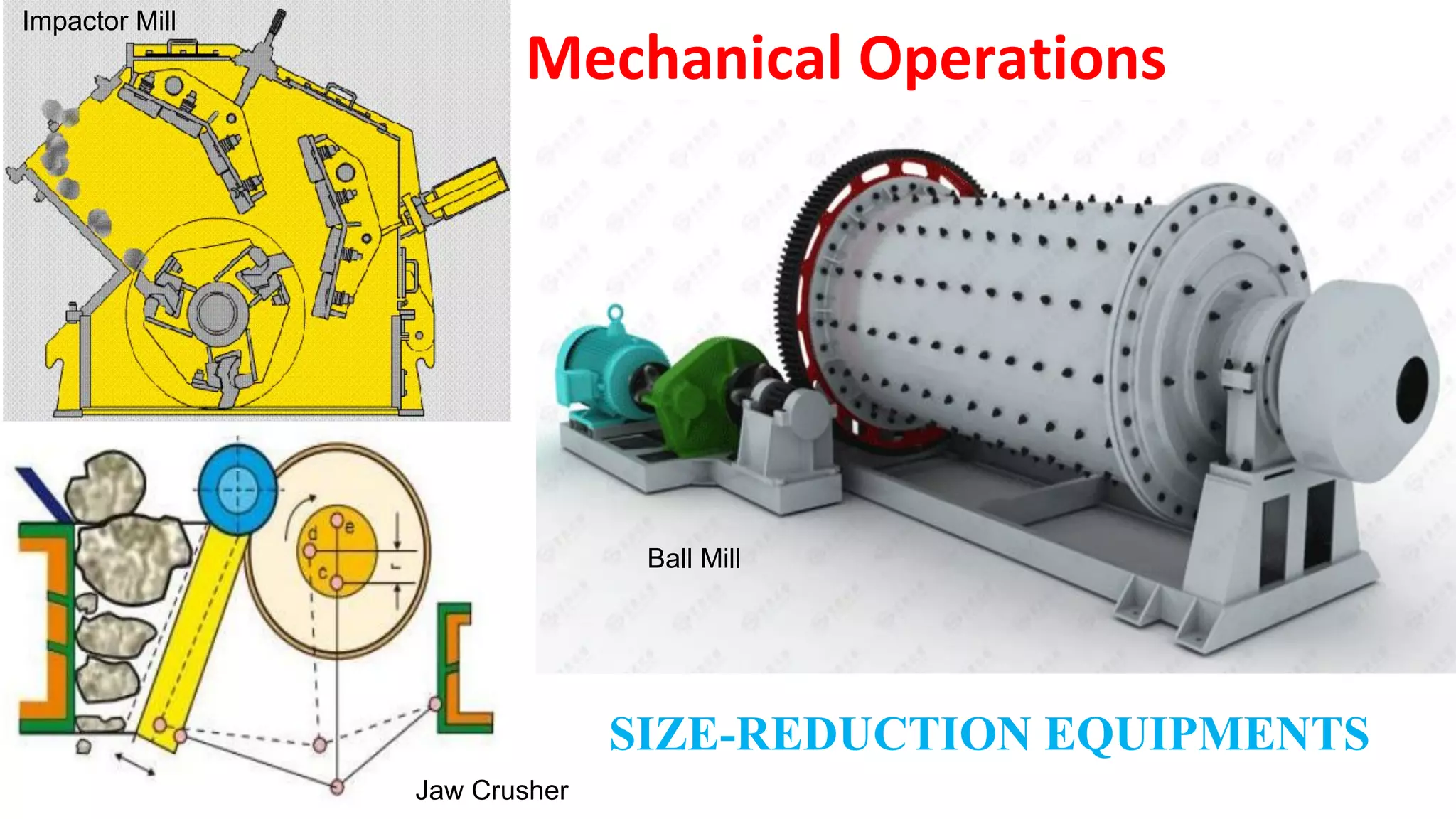

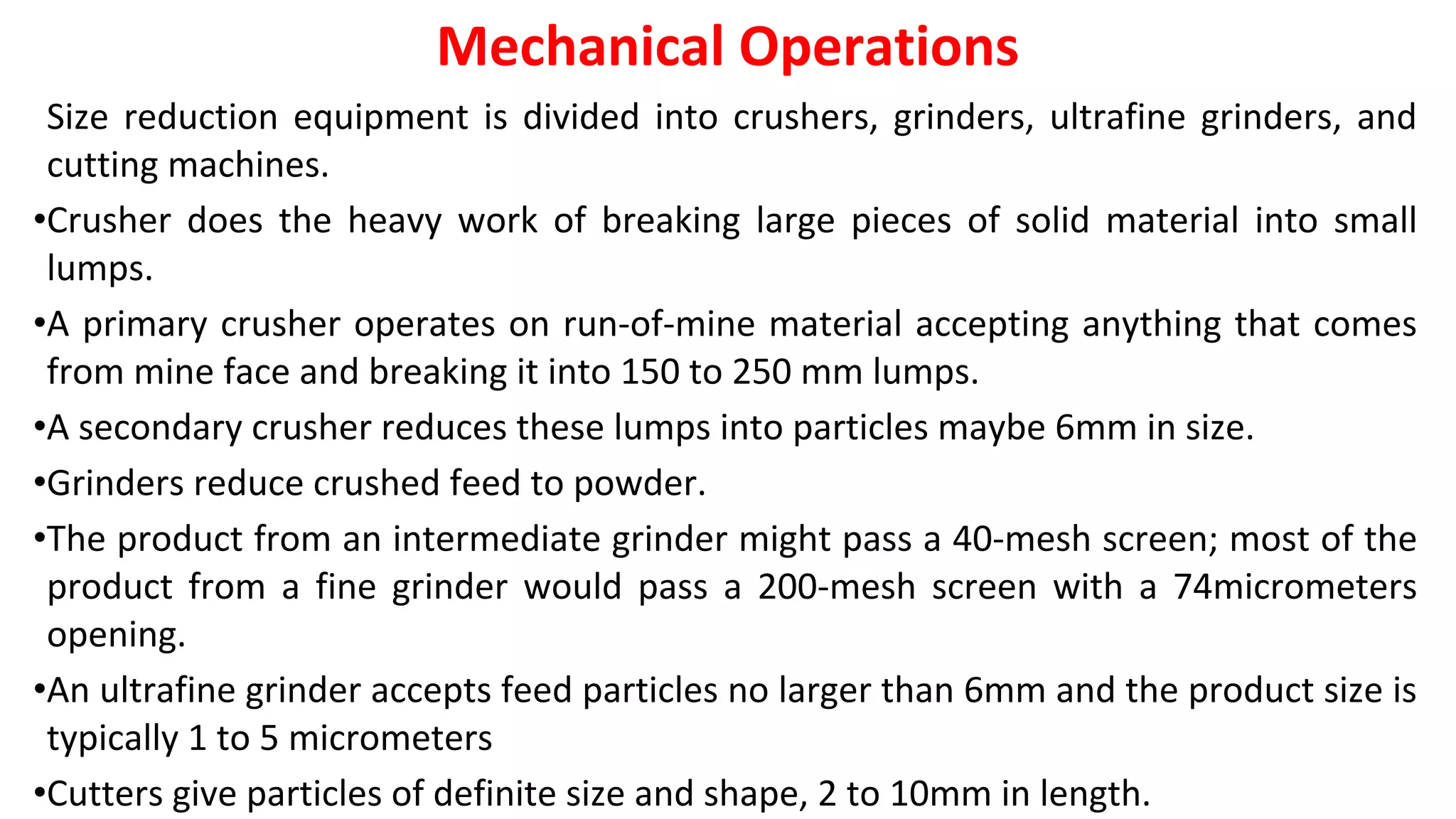

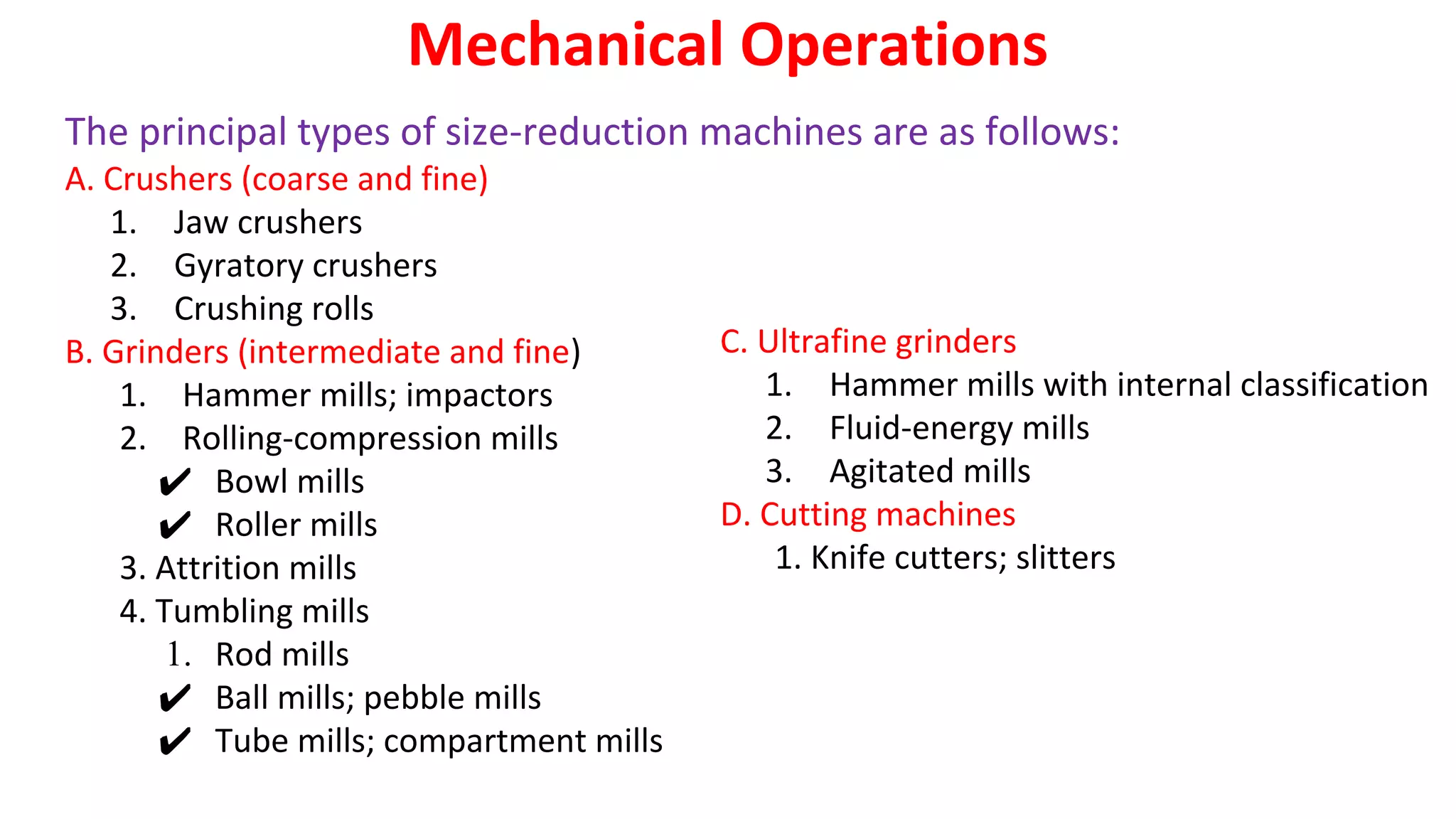

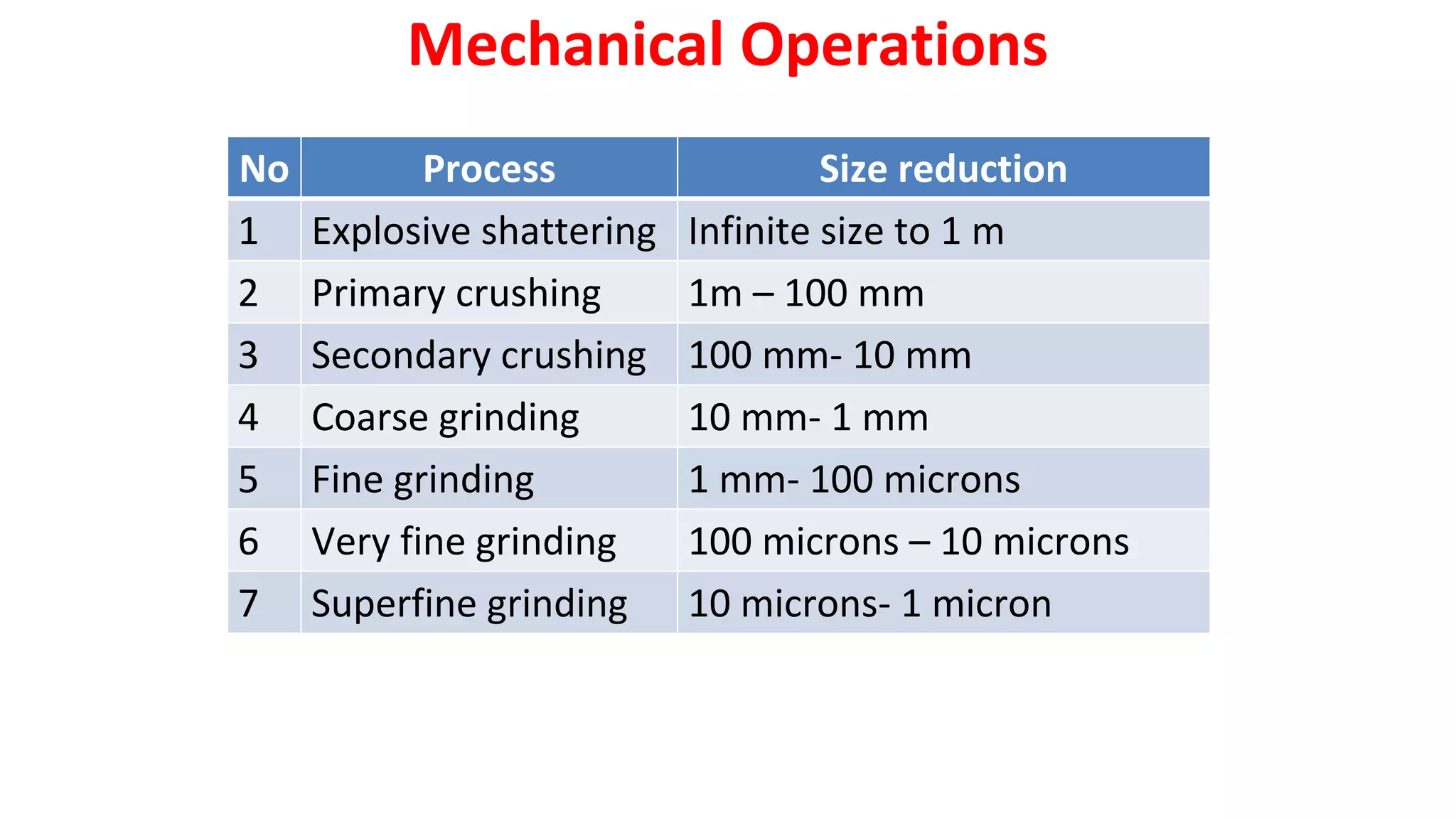

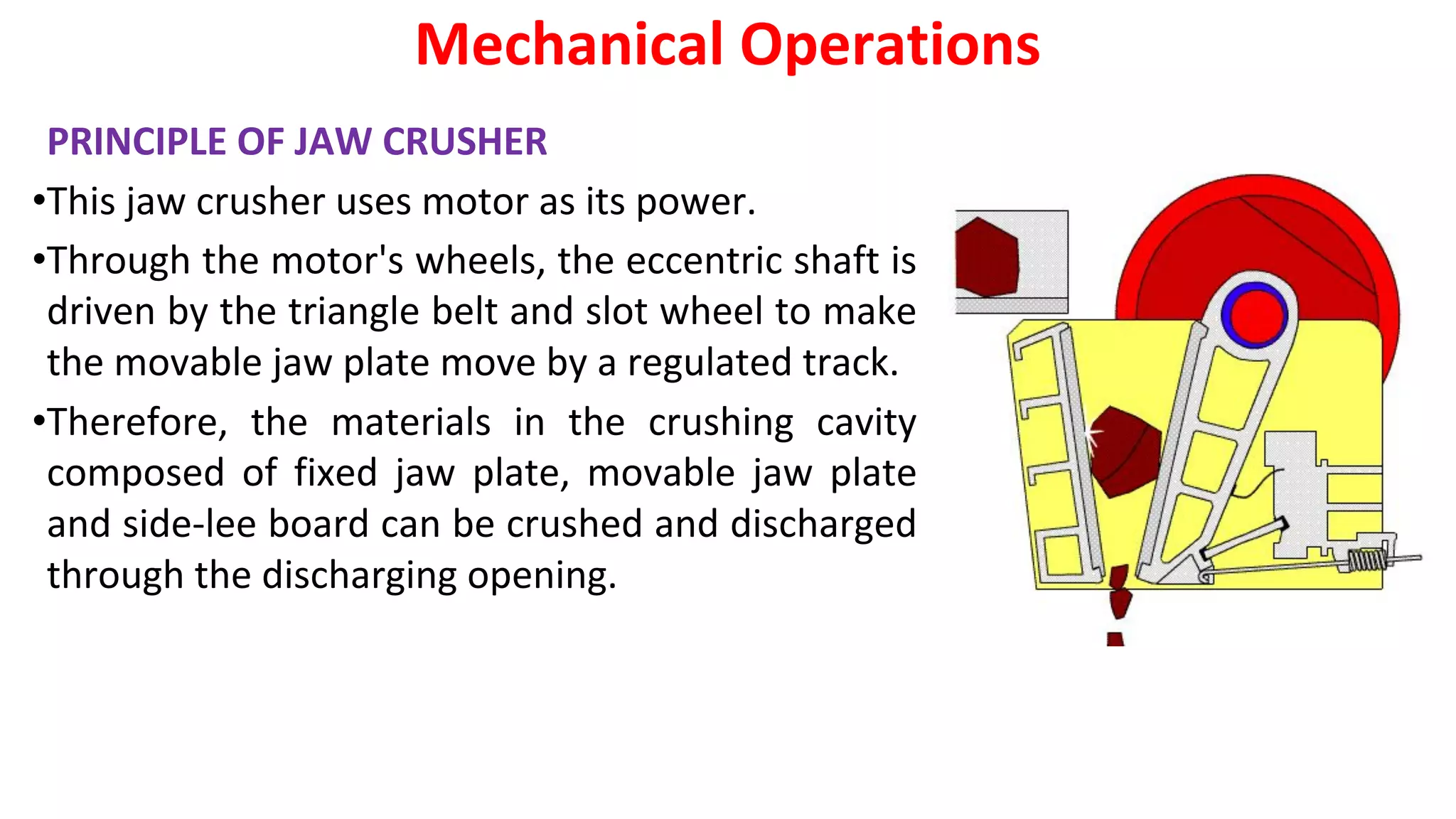

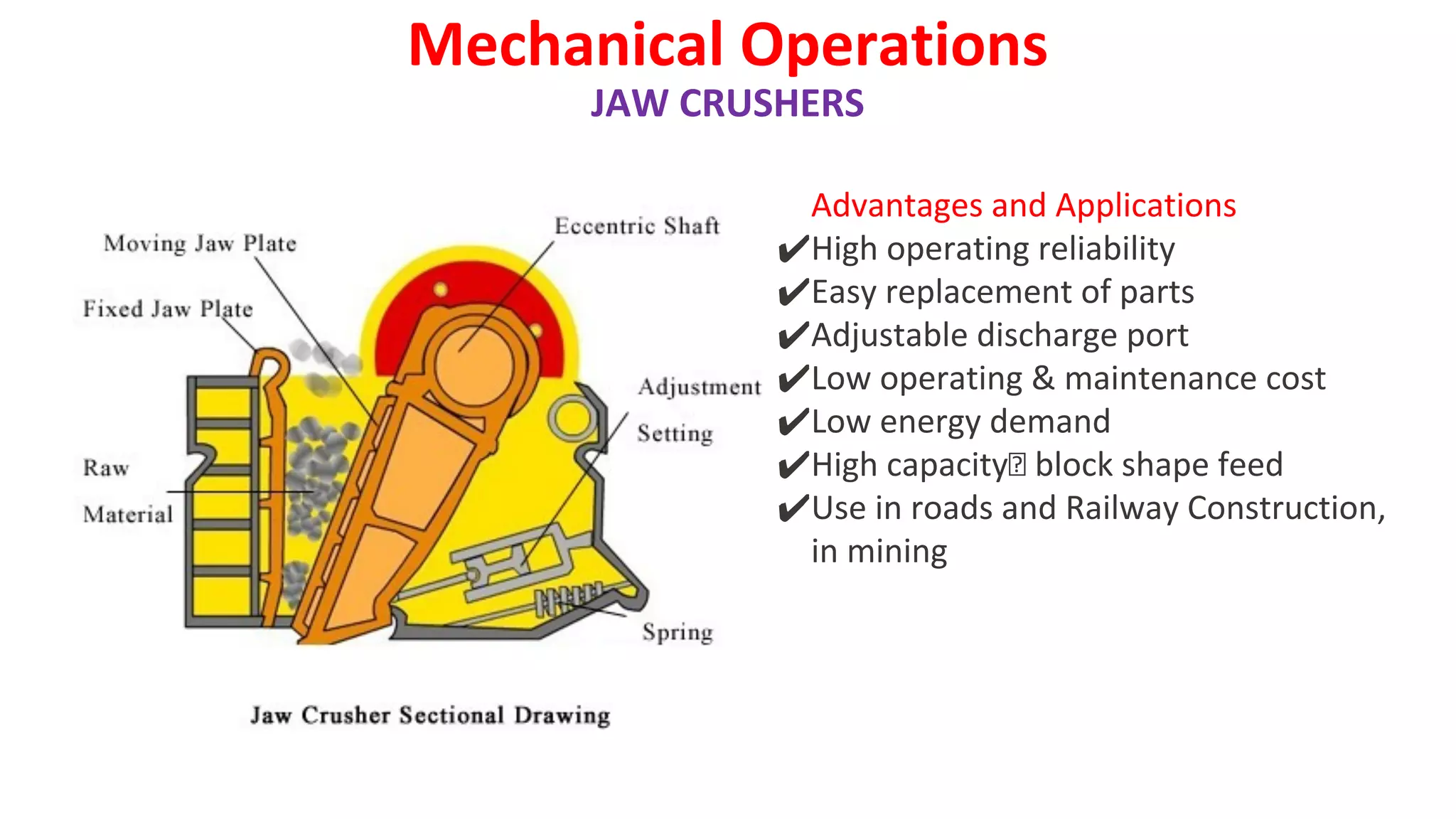

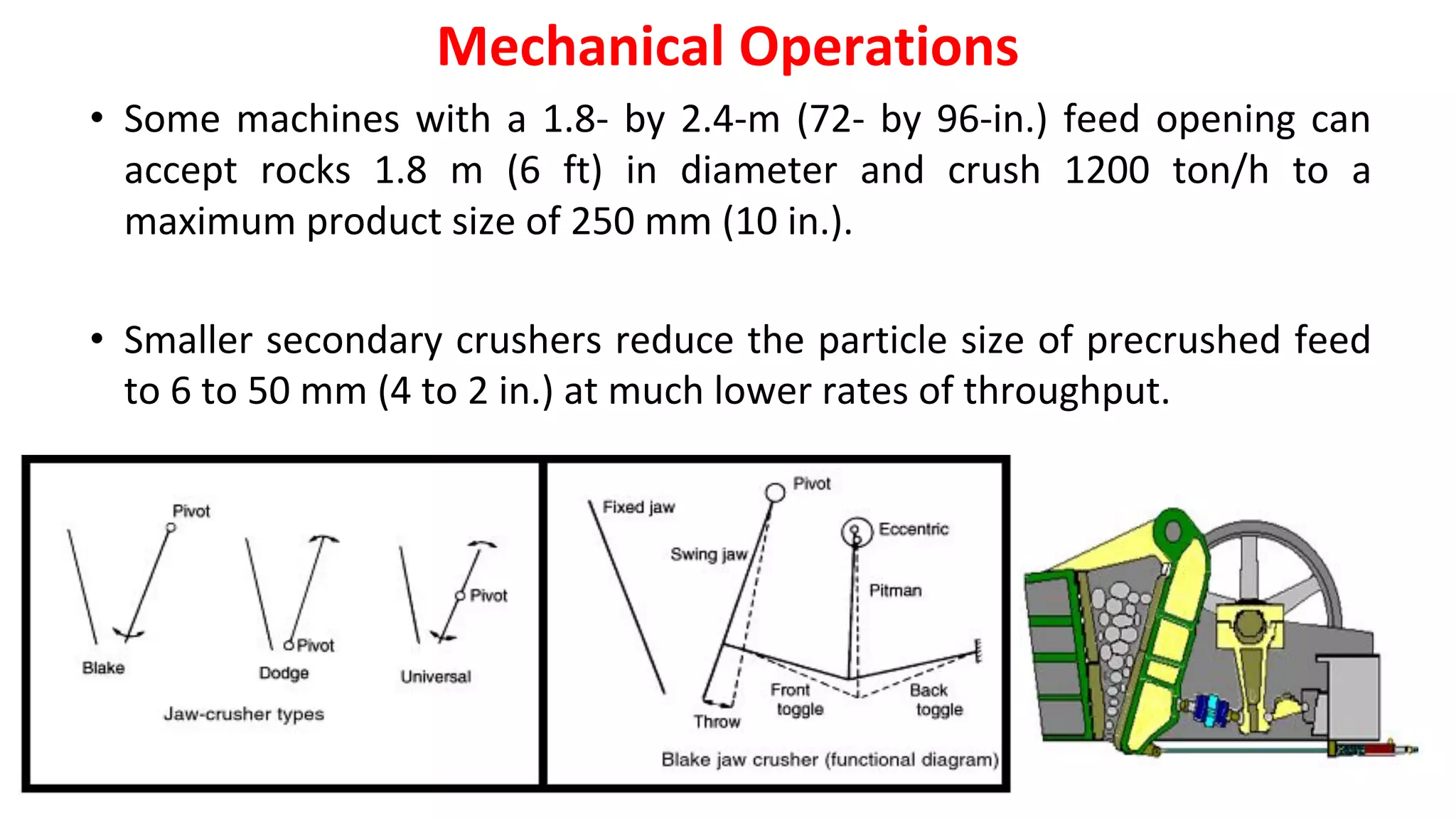

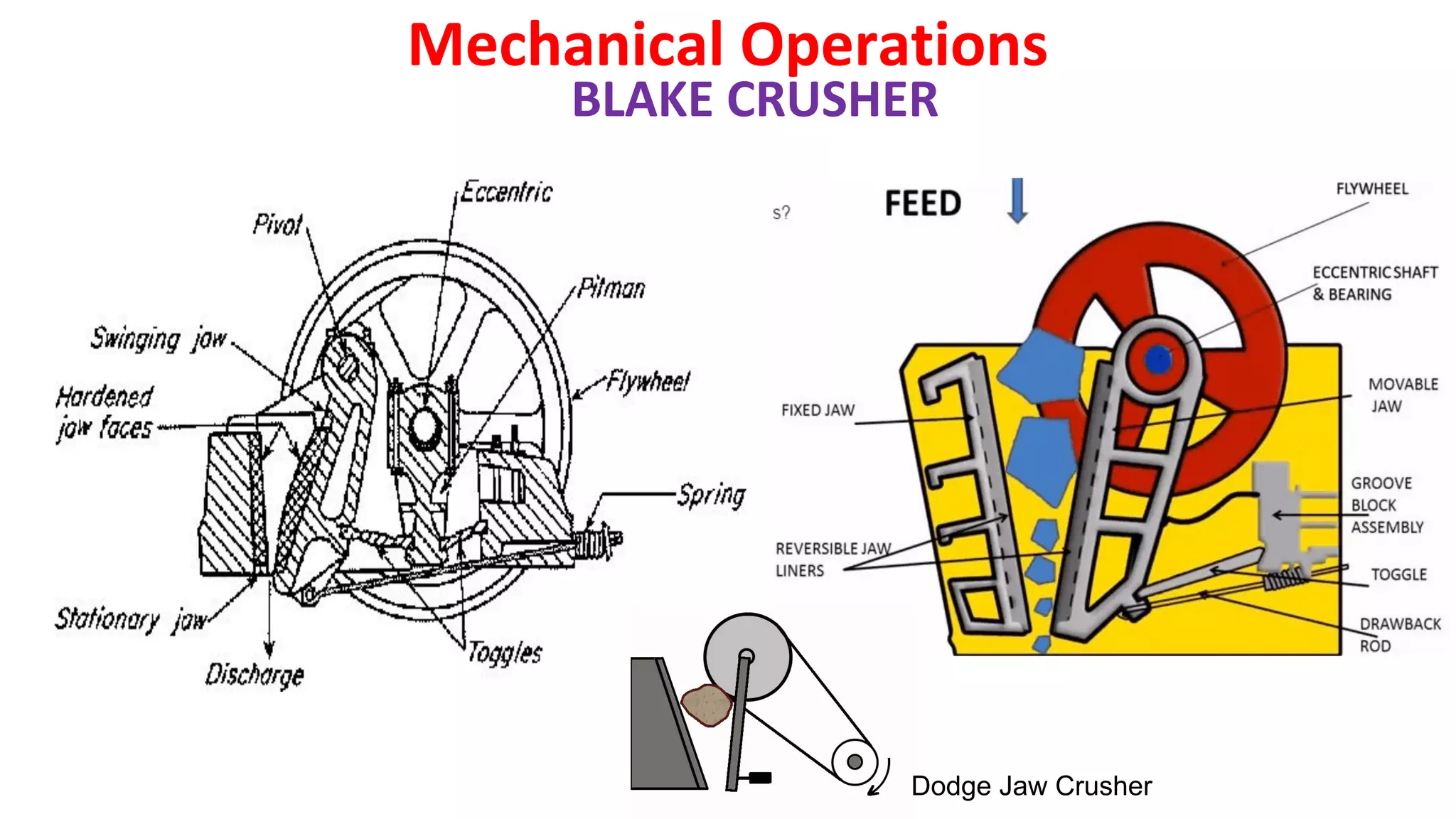

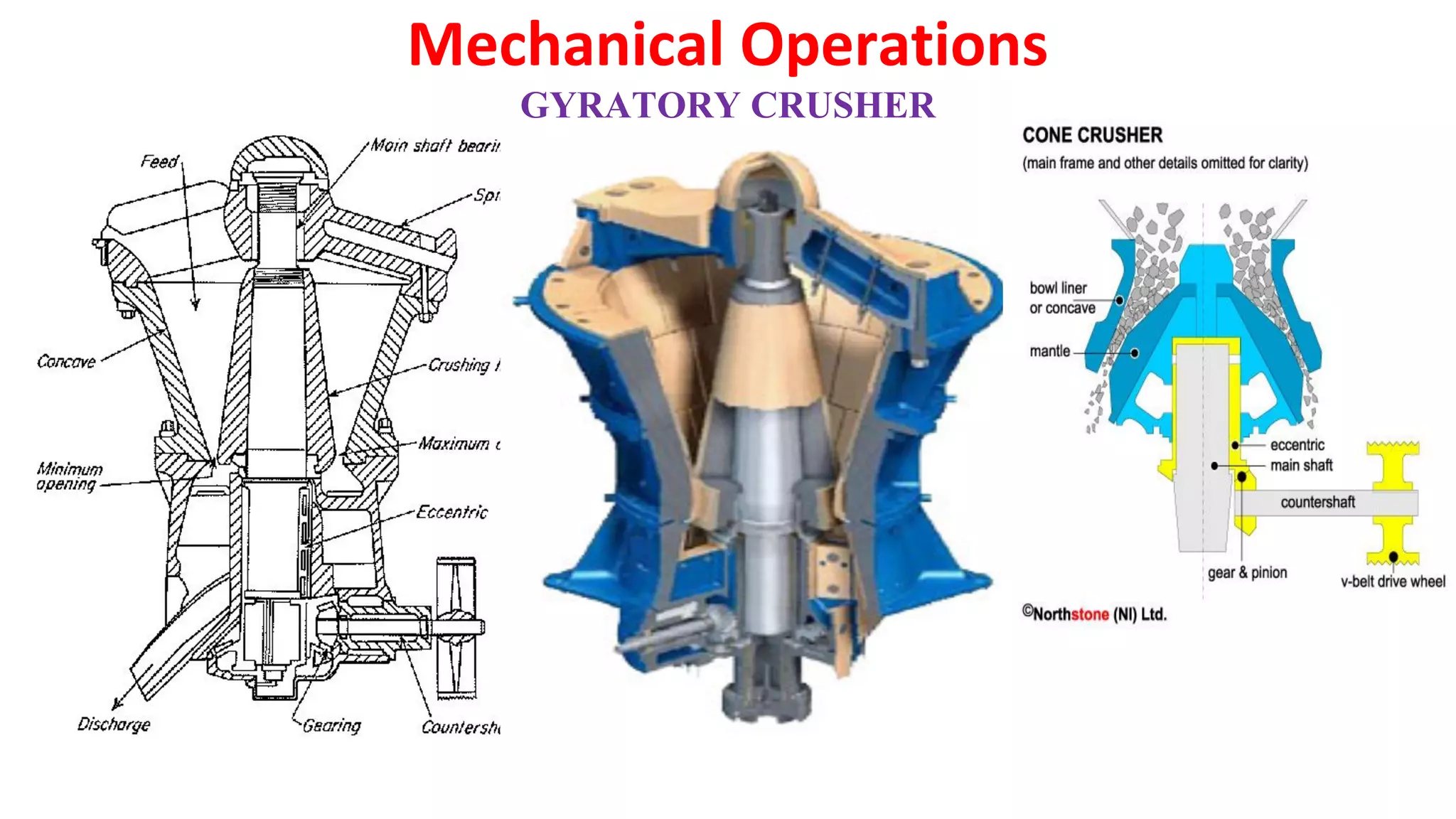

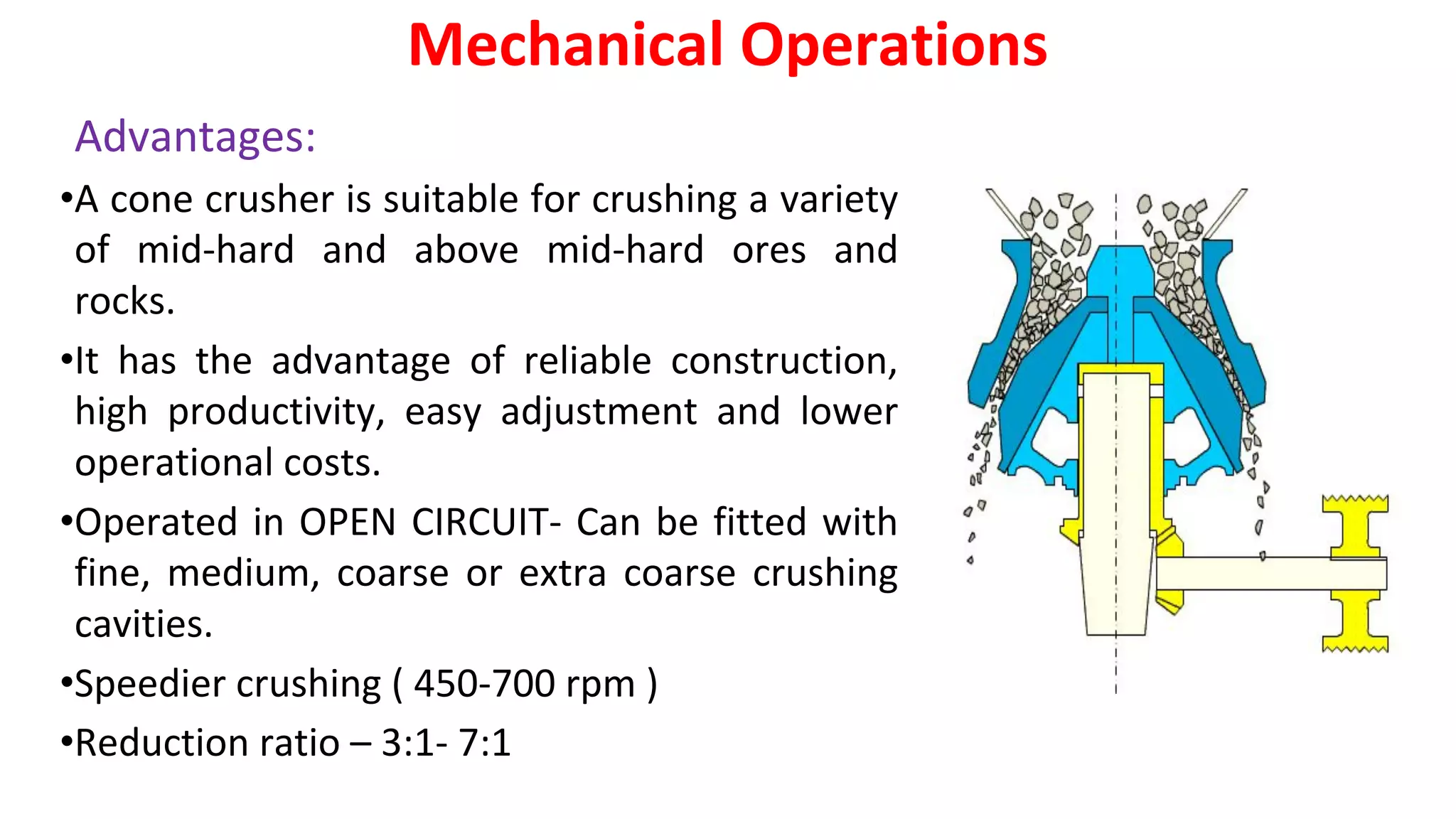

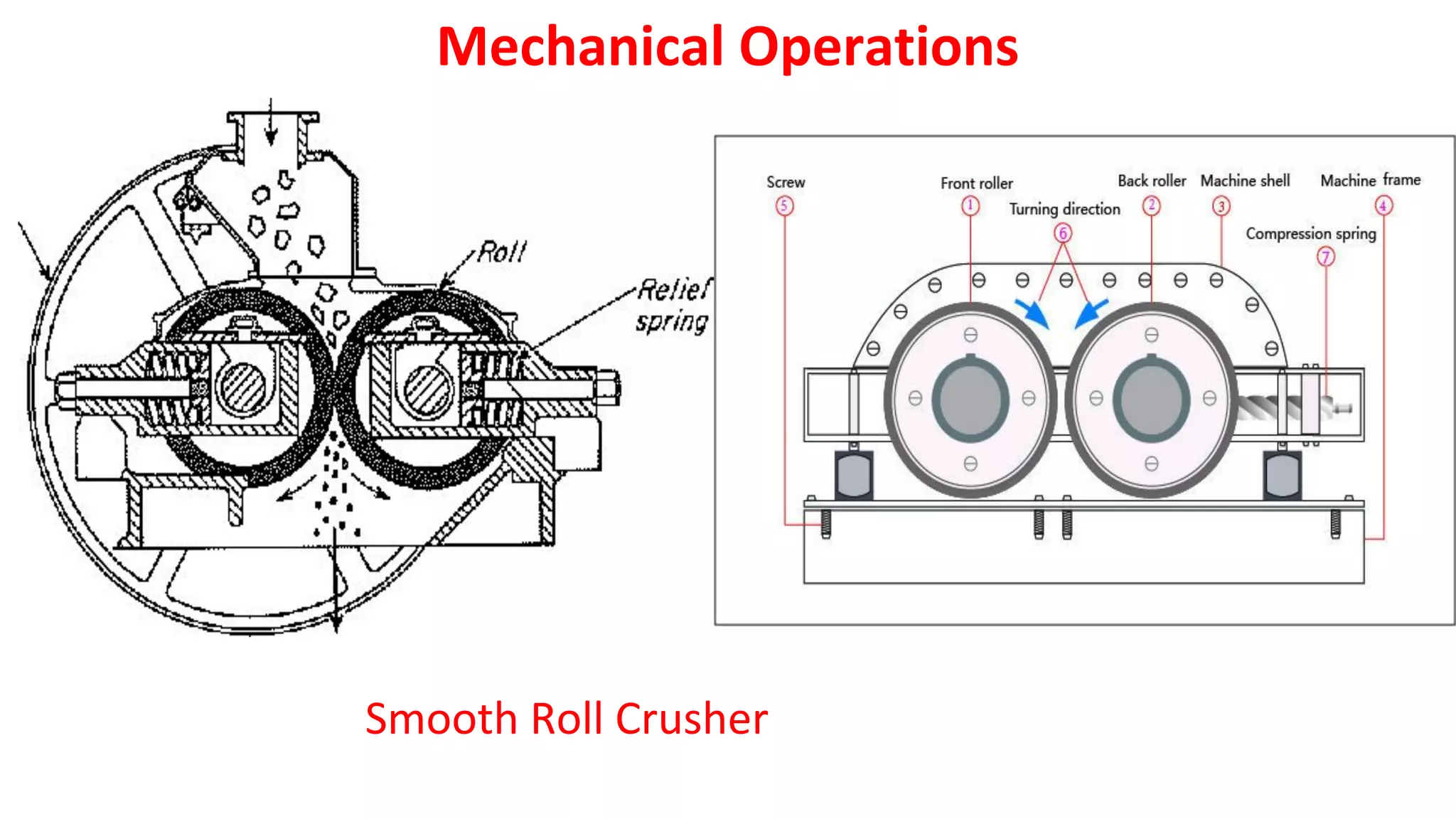

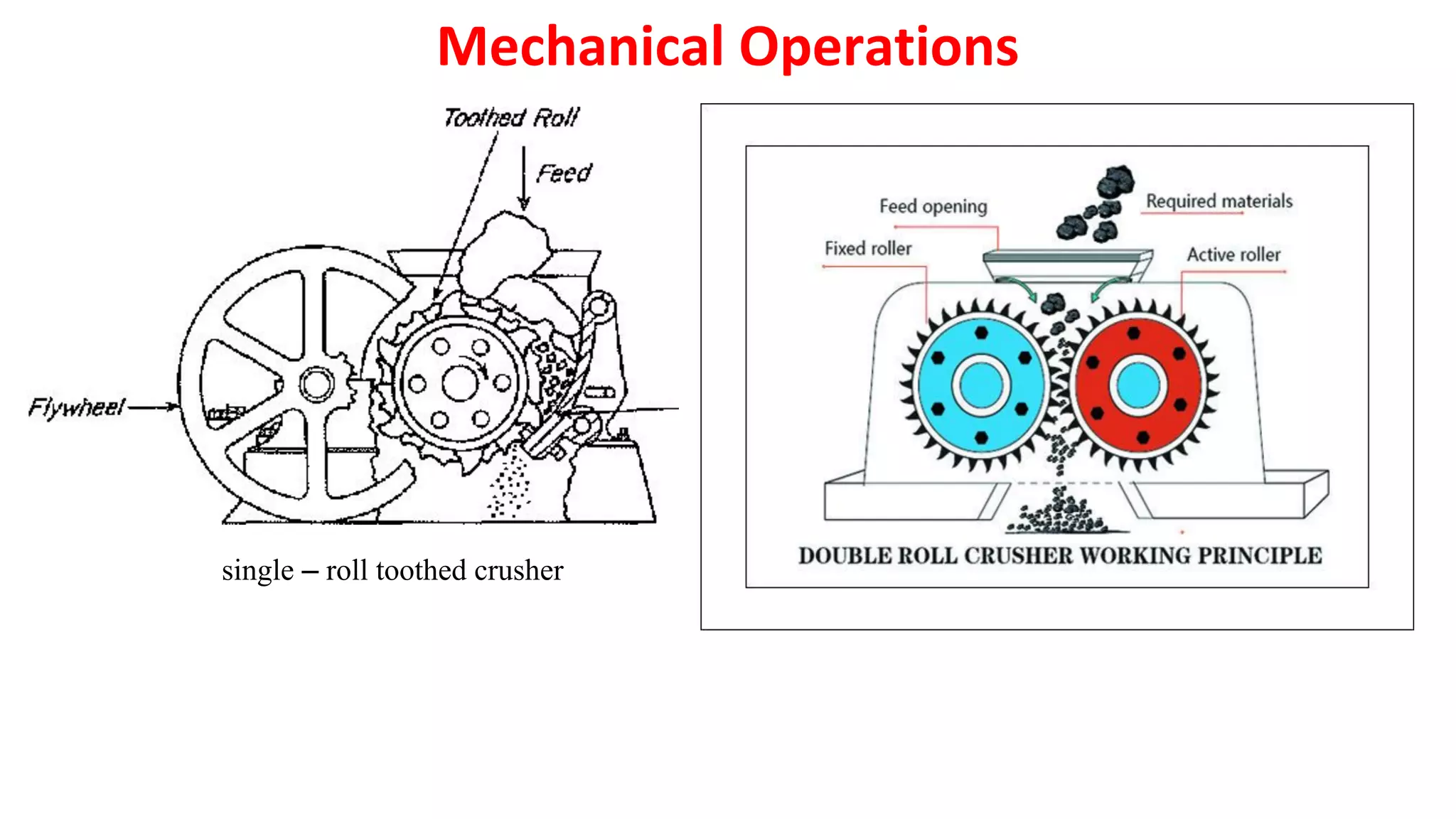

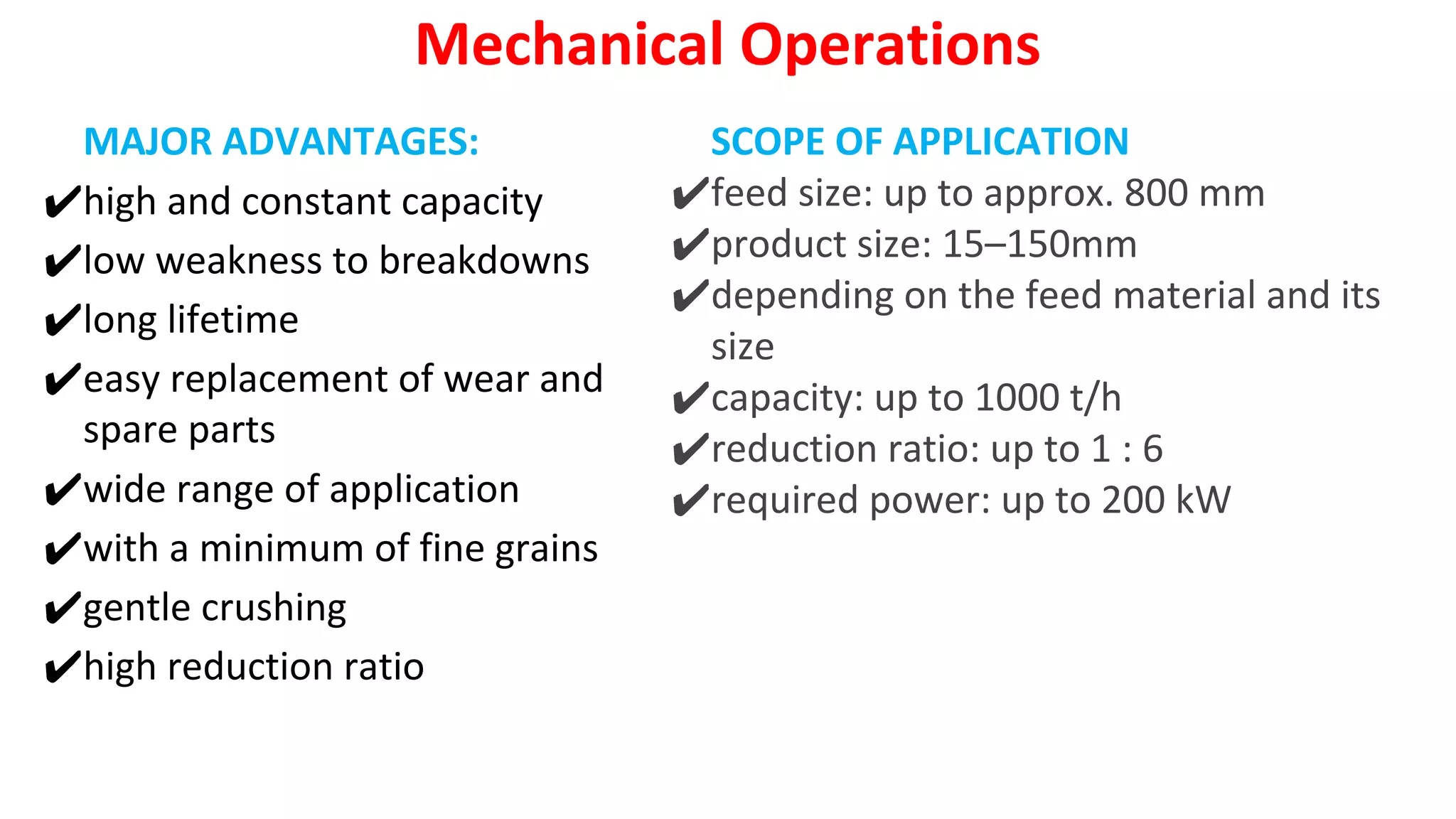

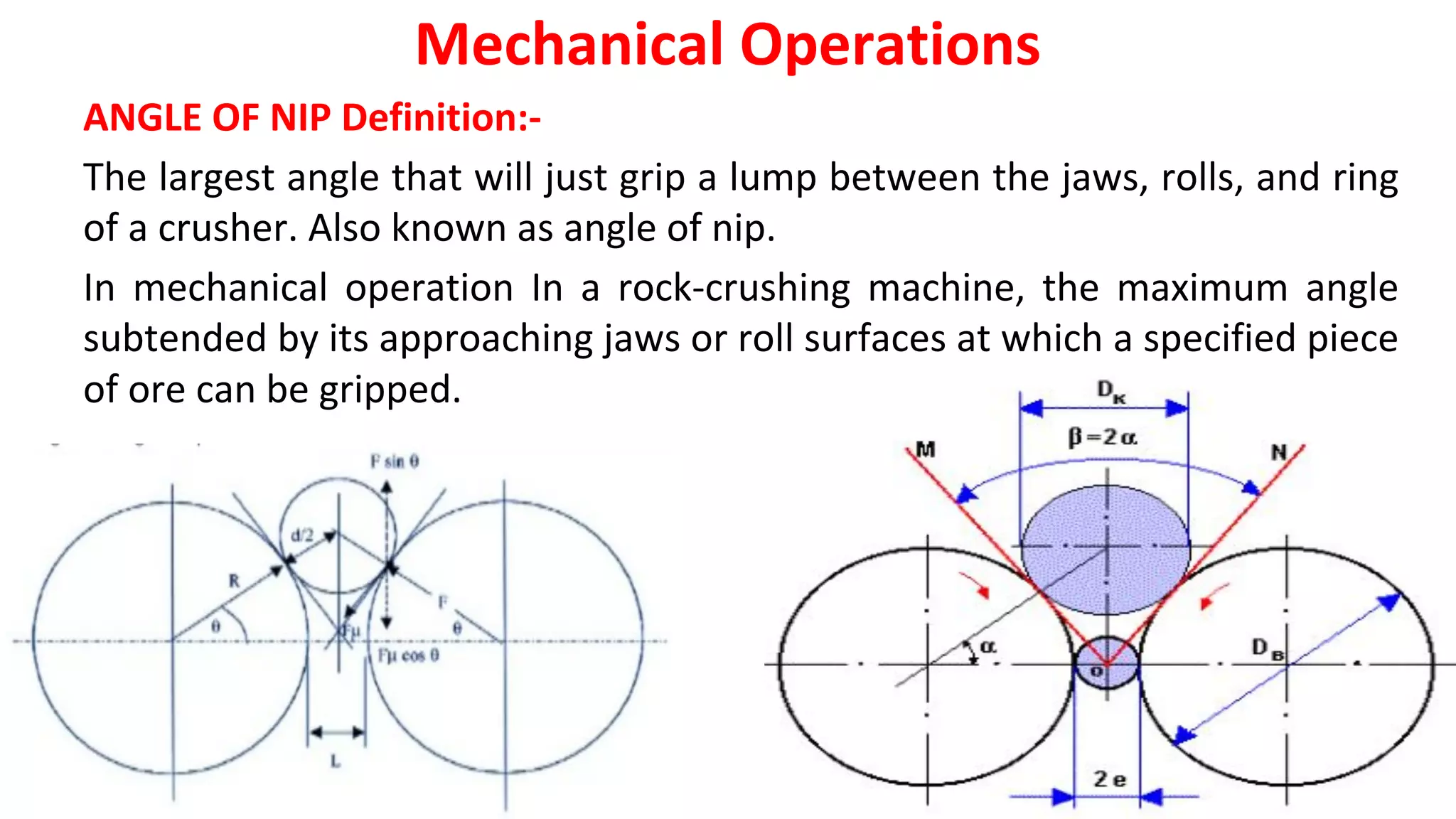

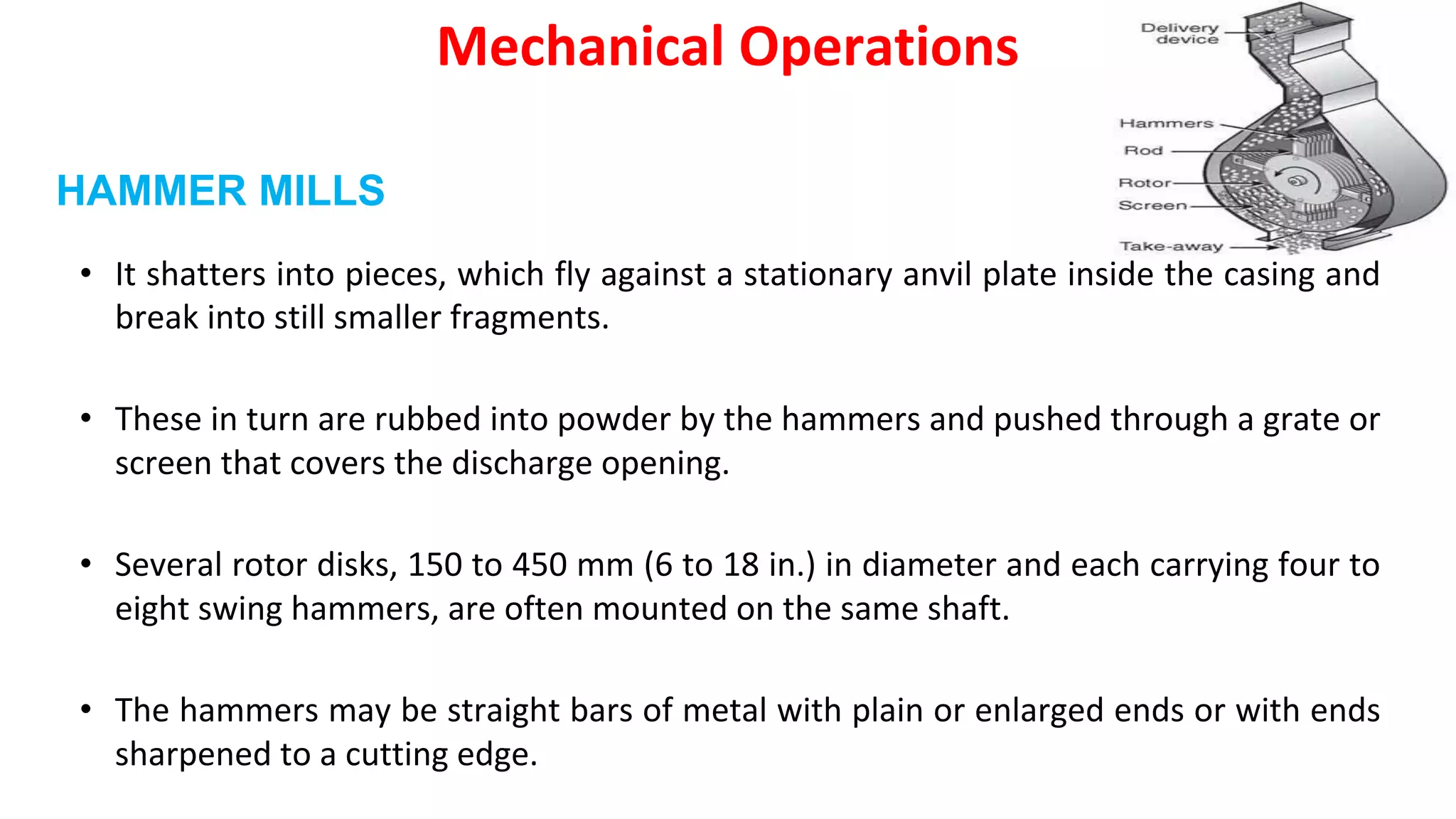

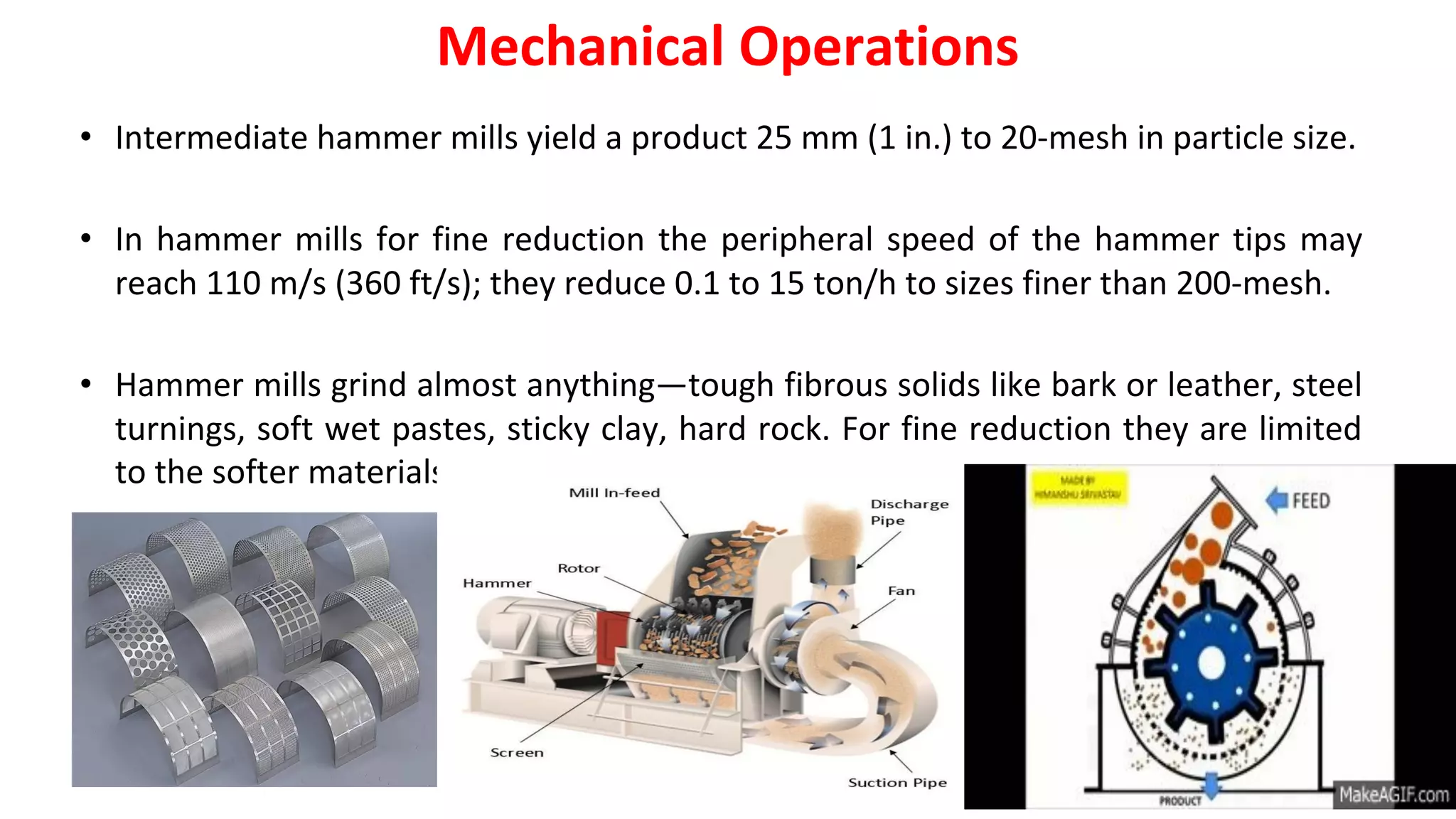

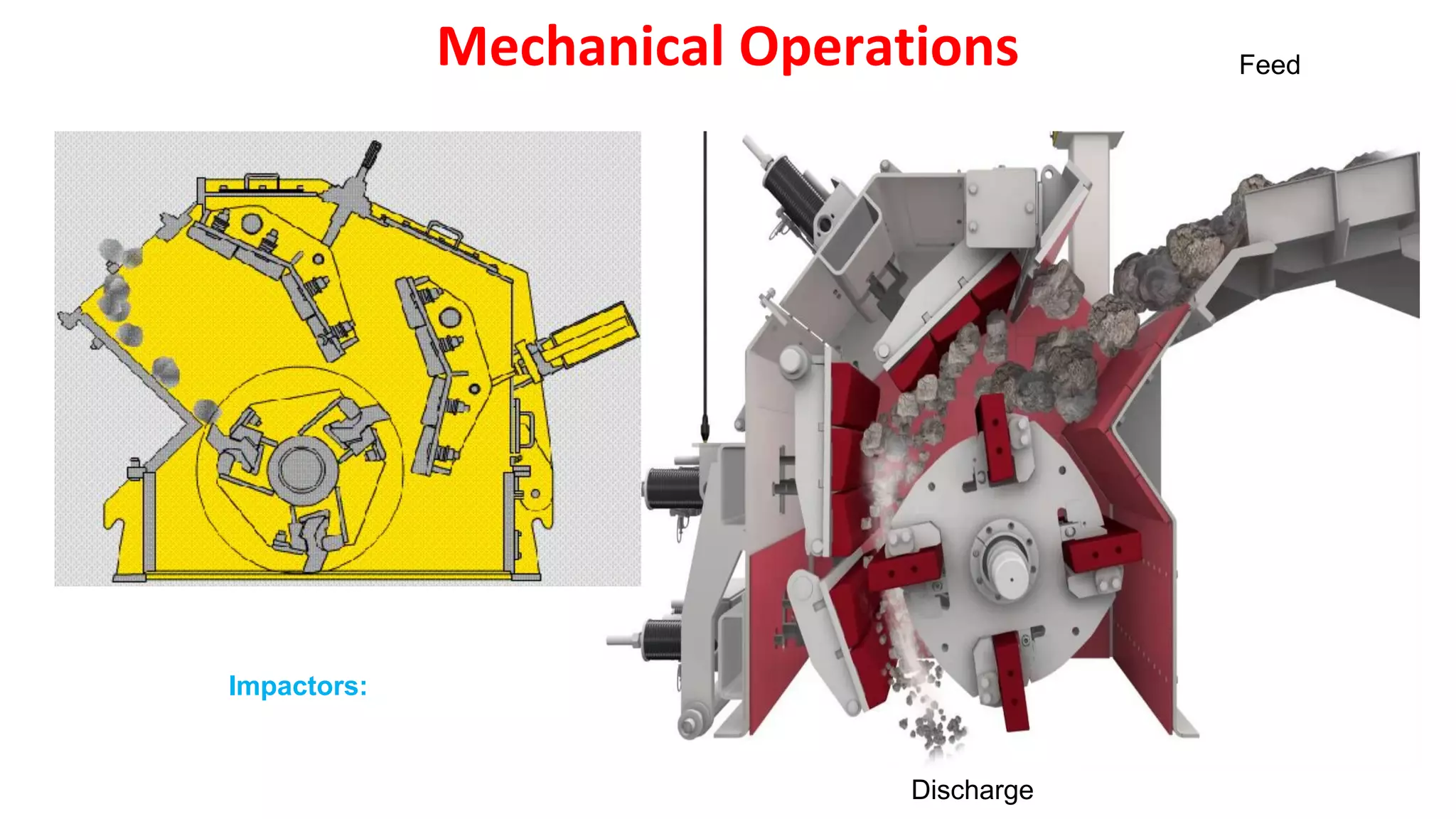

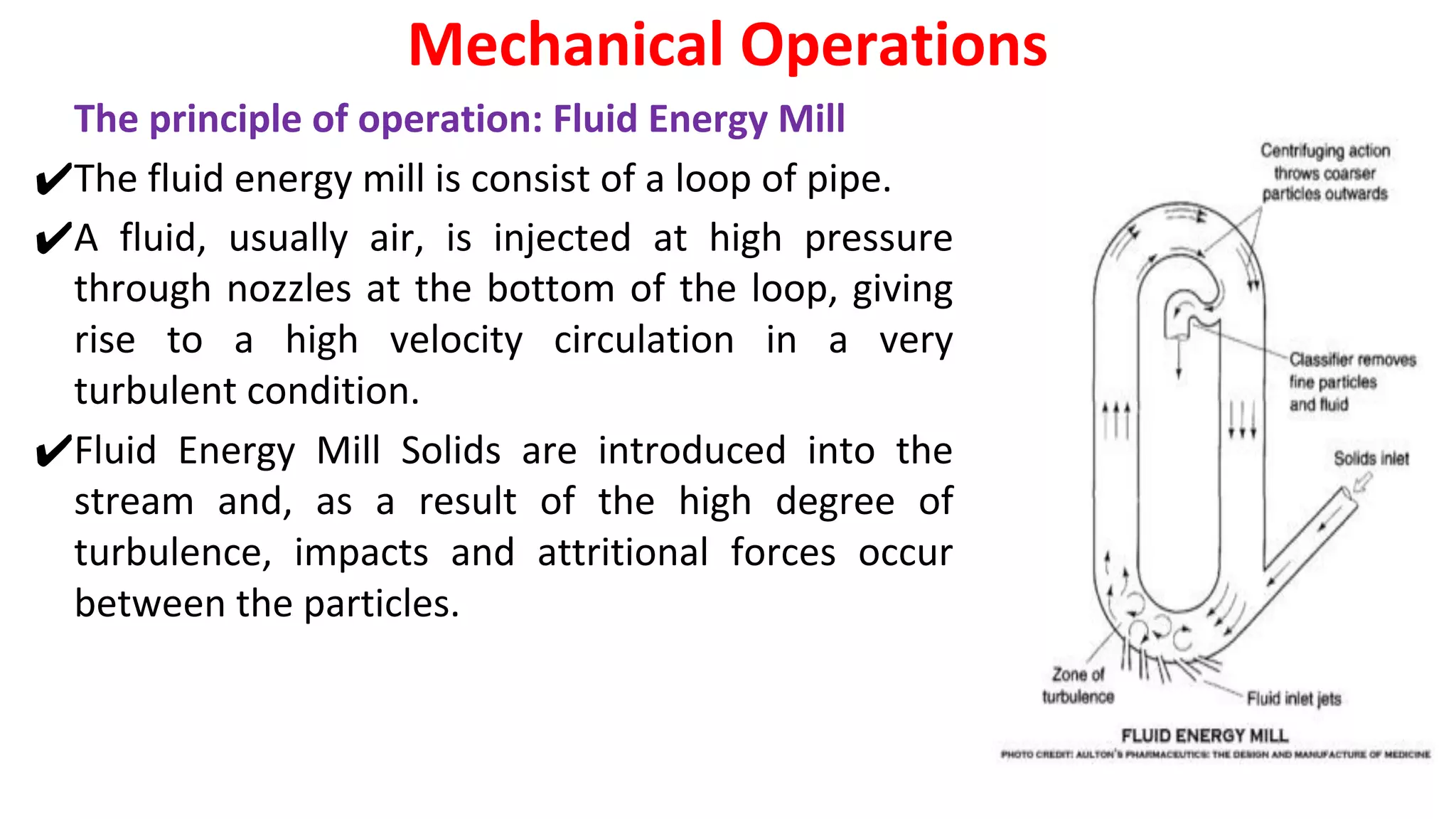

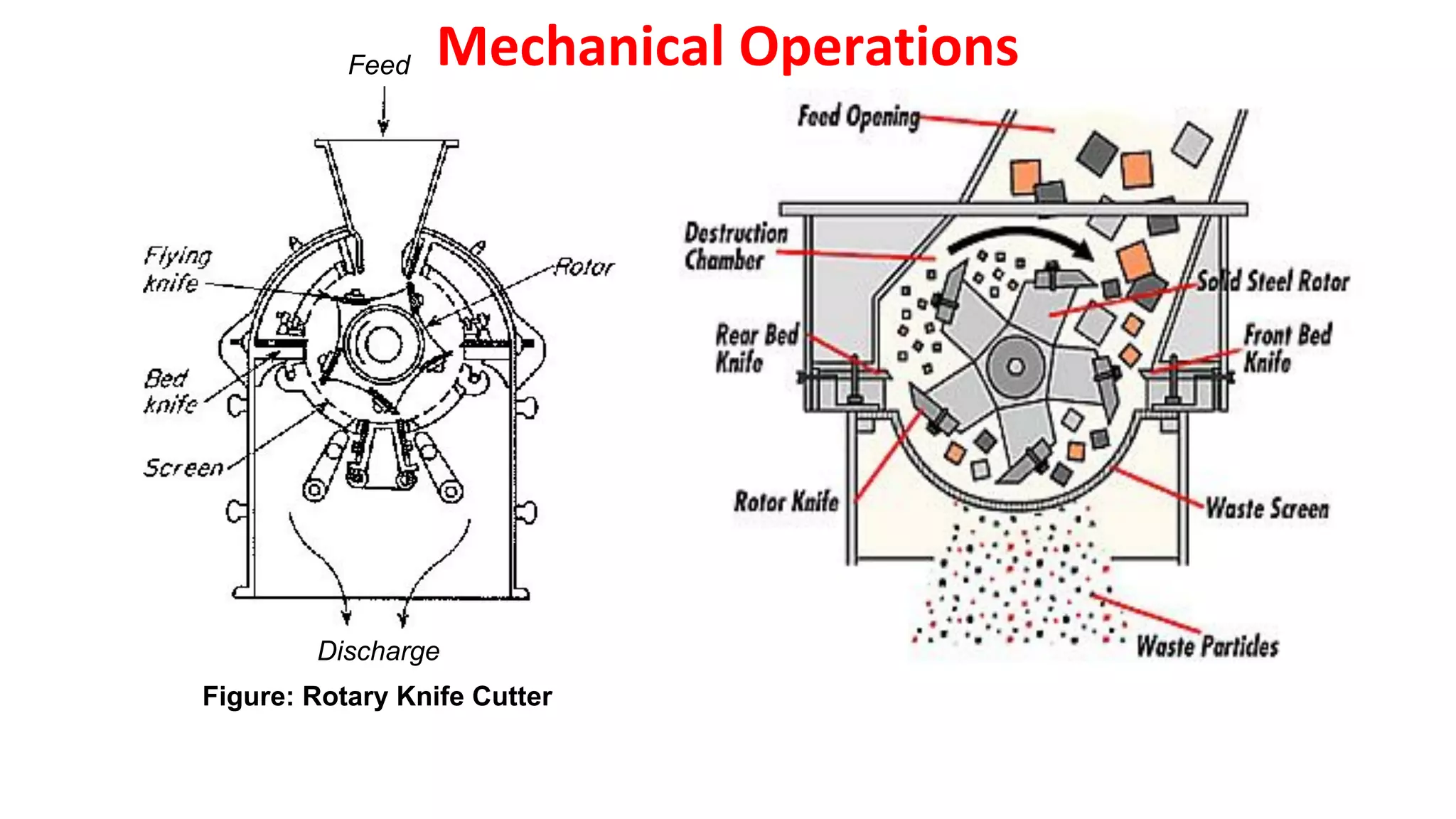

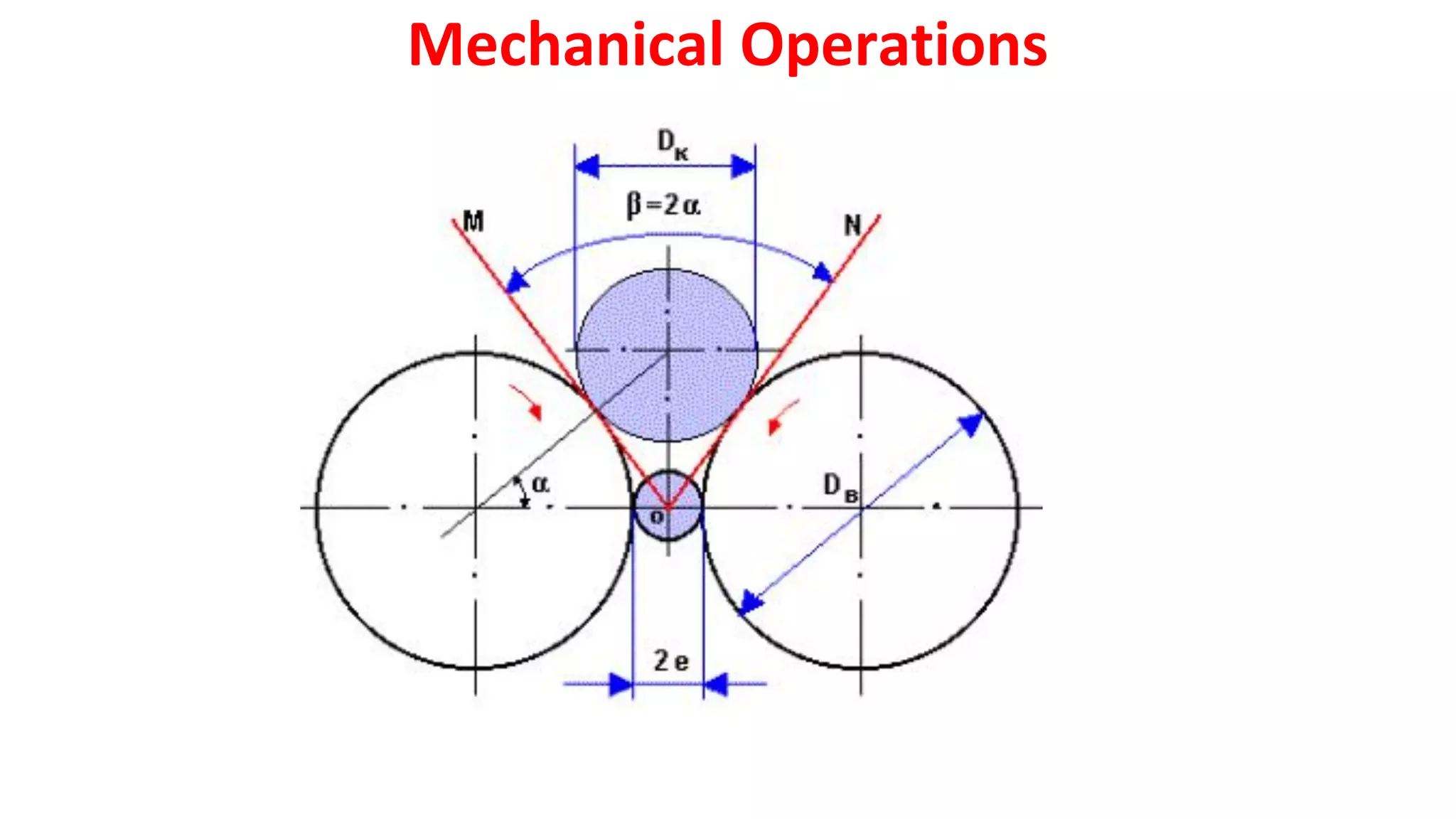

The document discusses various types of size-reduction equipment, including crushers, grinders, ultrafine grinders, and cutting machines. It describes the main types of crushers as jaw crushers, gyratory crushers, smooth-roll crushers, and toothed-roll crushers. Jaw crushers use compression to break large rocks into smaller pieces, while roll crushers employ compression to crush materials between two rolls. The document also provides details on the working principles and applications of different types of crushers.