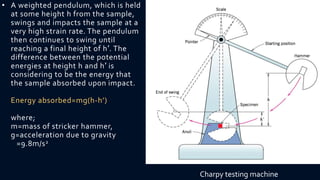

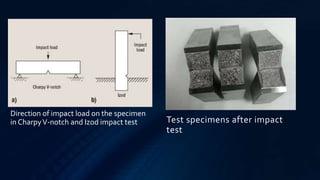

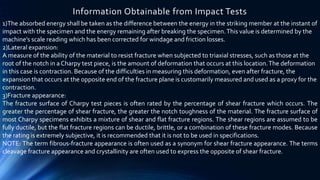

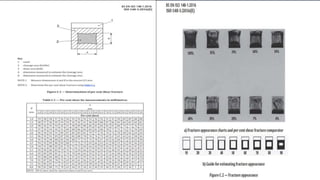

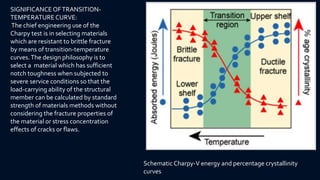

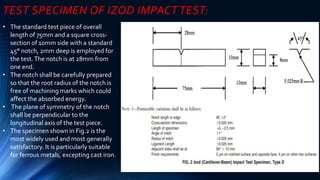

Impact testing is crucial for assessing the brittleness of metals, as standard tensile tests may not reveal their failure under sudden loads. The three primary types of impact tests—Charpy, Izod, and tensile impact—evaluate how materials behave when subjected to shock loads, and the results can indicate whether a metal is ductile or brittle. Charpy impact tests, often required for critical structures, measure the energy absorbed during fracture while providing insights into fracture appearance and material ductility.