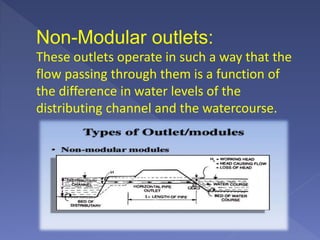

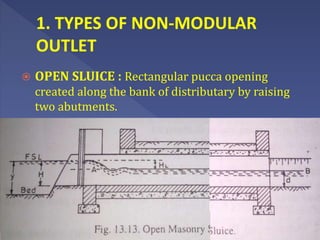

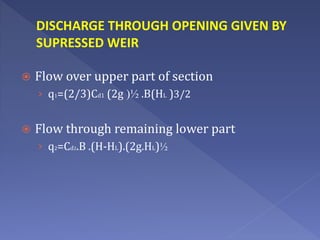

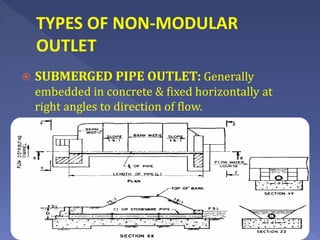

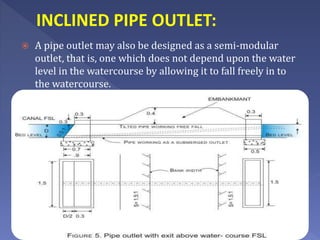

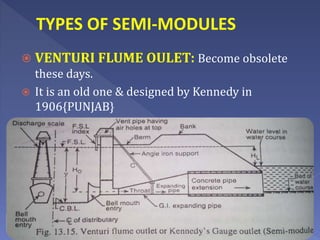

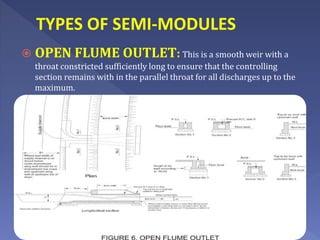

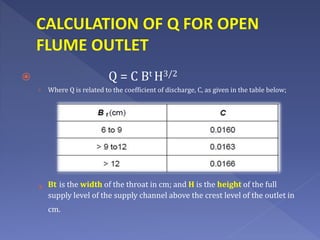

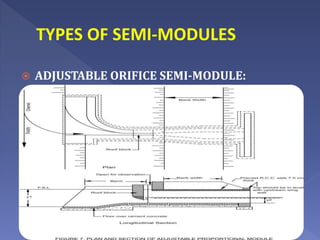

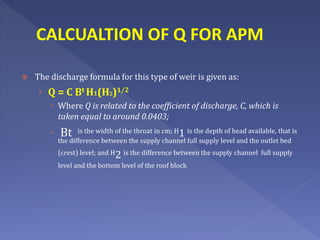

This document discusses different types of canal outlets used to release water from distributing channels into watercourses. It describes non-modular, semi-modular, and modular outlets. Non-modular outlets discharge based on water level differences, while modular outlets discharge independently of water levels. Semi-modular outlets discharge depending on the channel water level but not the watercourse level. Specific outlet types are also defined, such as pipe outlets, open sluice, and Gibbs, Khanna, and Foote rigid modules. Discharge equations for different outlet types are provided.