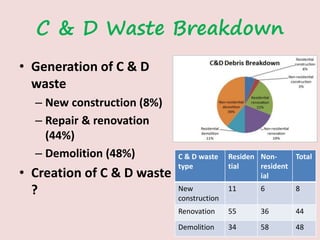

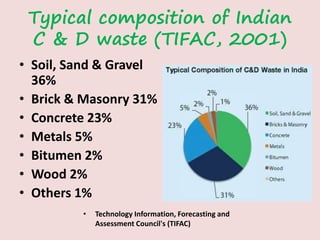

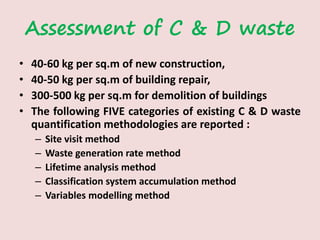

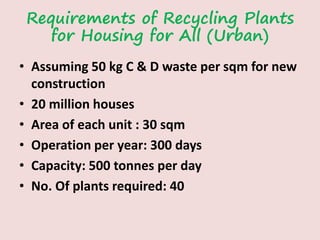

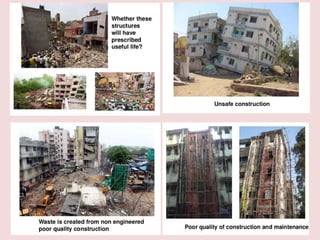

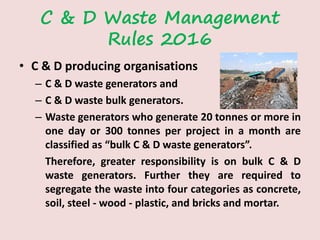

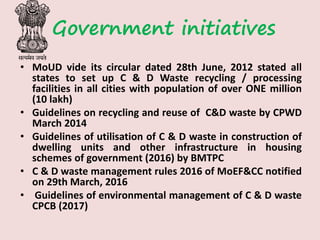

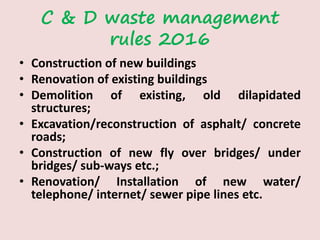

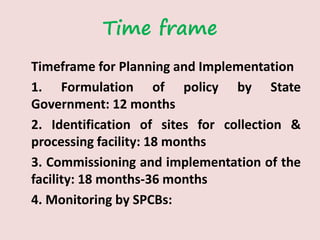

This document discusses construction and demolition (C&D) waste in India. It notes that C&D waste makes up a large portion of India's solid waste and estimates that 165-175 million tonnes of C&D waste are generated per year. It discusses government initiatives to increase recycling and use of recycled C&D waste in construction. These include guidelines from agencies like CPWD and BMTPC, as well as the C&D Waste Management Rules of 2016 which require segregation and processing of C&D waste. The document advocates increasing recycling and reuse of C&D waste to reduce impacts on landfills and natural resource extraction.